Ліст . 14, 2024 07:52 Back to list

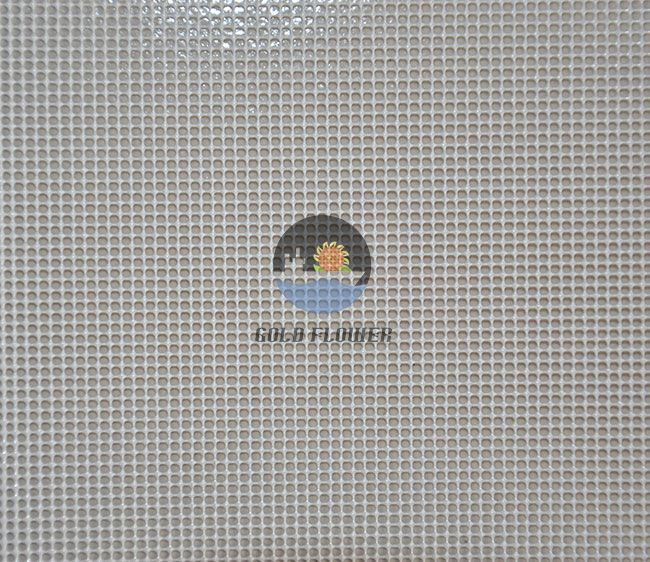

famous galvanised woven mesh

The Versatility of Galvanised Woven Mesh A Comprehensive Overview

Galvanised woven mesh is a remarkable material that has captured the attention of industries around the world. This type of mesh, typically crafted from high-quality steel wire, is treated with a galvanisation process that involves coating the metal with a layer of zinc. This treatment not only enhances the durability of the mesh but also provides excellent corrosion resistance, making it suitable for a wide range of applications.

Historical Context

The origins of woven mesh can be traced back to ancient civilizations, where early forms of mesh were used for various practical purposes. However, the galvanisation process was developed in the 19th century, revolutionizing the use of wire products. The introduction of galvanised woven mesh marked a significant milestone, leading to widespread adoption in construction, agriculture, and numerous other sectors.

Key Characteristics

Galvanised woven mesh is known for its distinctive characteristics. The mesh is available in various sizes, shapes, and wire thicknesses, making it highly customizable. Its unique woven structure provides strength and flexibility, allowing it to withstand tensile stresses while maintaining structural integrity. The zinc coating ensures that the mesh is resistant to rust, which is particularly advantageous in outdoor environments where exposure to moisture and harsh weather conditions can lead to rapid deterioration.

Applications in Various Industries

1. Construction and Building One of the most common applications of galvanised woven mesh is in the construction industry. It is often used as reinforcement in concrete, providing additional strength to structures. Additionally, it serves as a barrier in various building projects, preventing debris from entering work areas while still allowing for visibility and ventilation.

famous galvanised woven mesh

2. Agriculture In agricultural applications, galvanised woven mesh plays a crucial role in fencing and enclosures. Farmers utilize this material to protect crops and livestock from predators and harsh weather. The mesh is durable enough to withstand outdoor conditions, making it an ideal choice for long-term agricultural solutions.

3. Industrial Use Many manufacturing and industrial facilities employ galvanised woven mesh for safety and functionality. It is often used in machinery guards, walkways, and safety screens. The visibility provided by the mesh allows for monitoring without sacrificing safety, which is essential in busy industrial settings.

4. Mining and Quarrying In the mining sector, galvanised woven mesh is critical for controlling dust and supporting structures. Its robust nature allows it to endure the rough environment of mines and quarries, ensuring that it remains effective over time.

5. DIY and Home Improvement Beyond industrial applications, galvanised woven mesh is popular among DIY enthusiasts. It can be used for various home improvement projects, from creating garden trellises to crafting decorative elements. The versatility and ease of handling make it a favorite choice for many home-based projects.

Environmental Considerations

As sustainability becomes an increasingly important focus for industries, galvanised woven mesh stands out as an environmentally friendly option. The galvanisation process extends the lifespan of the wire, reducing the need for frequent replacements. Furthermore, at the end of its life cycle, the steel can be recycled, contributing to a circular economy and minimizing waste.

Conclusion

Galvanised woven mesh is a versatile and durable material that has earned its place in various industries due to its strength, flexibility, and resistance to corrosion. From construction and agriculture to industrial applications and DIY projects, the range of uses for this material continues to grow. As industries aim for more sustainable practices, galvanised woven mesh also contributes positively by promoting longevity and recyclability. With its historical roots and modern innovations, galvanised woven mesh remains a fundamental component in a myriad of applications, proving that it is indeed a noteworthy material in today's world.

share

-

Black Chain Link Fence Costs Affordable Pricing & Installation Estimates

NewsMay.18,2025

-

Stainless Steel Chicken Mesh Durable & Corrosion-Resistant Fencing

NewsMay.18,2025

-

Affordable Cabin Air Filter Cost & Replacement Tips Save Now!

NewsMay.17,2025

-

Top-Rated Good Air Purifiers Clean Air & Allergy Relief

NewsMay.17,2025

-

ODM Brass Wire Mesh Screens Custom Sizes & Antique Finishes

NewsMay.16,2025

-

China Netting Fence Wire - Durable & Fox Proof Wire Mesh Solutions

NewsMay.16,2025