Úno . 14, 2025 11:31 Back to list

buy woven wire mesh screen

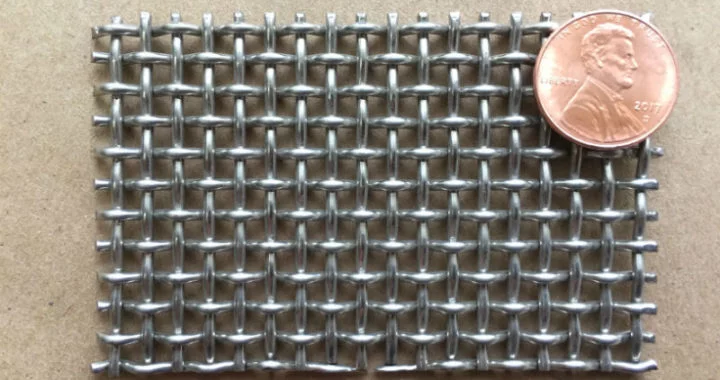

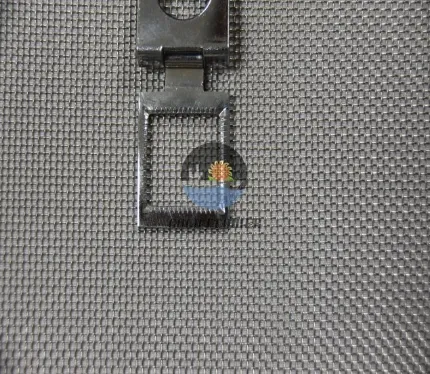

Woven wire mesh screens have become an indispensable component in various industries, from manufacturing to architecture. As businesses and individuals seek reliable and effective solutions for filtration, separation, and design, selecting the right woven wire mesh screen not only ensures efficiency but also guarantees durability and satisfaction. This guide explores the crucial aspects of purchasing woven wire mesh screens, emphasizing the essential qualities that bolster decision-making processes and instilling confidence in prospective buyers.

The customization options available offer added value. From bespoke sizes and shapes to specialty coatings that improve performance—such as anti-rust treatments or heat-resistant coatings—having a tailored solution can greatly enhance productivity and lifespan in specific environments. Consulting with industry experts who can offer guidance on these options ensures that the investment made caters precisely to operational demands. Logistics should not be overlooked during the purchasing process. Timely delivery and after-sales service contribute significantly to customer satisfaction. Engaging with suppliers who have a robust distribution network ensures that products arrive as expected, minimizing downtime and maintaining operational continuity. Furthermore, companies that provide comprehensive support services, including installation assistance and technical consultation, build trust and long-term partnerships with their clients. Lastly, sustainability considerations are becoming increasingly important. Opting for suppliers who employ eco-friendly manufacturing processes and materials promotes environmental responsibility. But beyond the ecological impact, sustainable practices often reflect a company’s overall commitment to quality and care, fostering a culture of trustworthiness and integrity that resonates throughout their business operations. In conclusion, purchasing a woven wire mesh screen requires a diligent approach that considers materiality, functionality, quality assurance, customization, and logistics. By making informed decisions based on these parameters, businesses and individuals can optimize operational efficiency, reduce costs, and ensure long-term satisfaction with their choice. The expertise and resources provided by reputable suppliers not only elevate the purchasing experience but also establish a dependable foundation for future endeavors.

The customization options available offer added value. From bespoke sizes and shapes to specialty coatings that improve performance—such as anti-rust treatments or heat-resistant coatings—having a tailored solution can greatly enhance productivity and lifespan in specific environments. Consulting with industry experts who can offer guidance on these options ensures that the investment made caters precisely to operational demands. Logistics should not be overlooked during the purchasing process. Timely delivery and after-sales service contribute significantly to customer satisfaction. Engaging with suppliers who have a robust distribution network ensures that products arrive as expected, minimizing downtime and maintaining operational continuity. Furthermore, companies that provide comprehensive support services, including installation assistance and technical consultation, build trust and long-term partnerships with their clients. Lastly, sustainability considerations are becoming increasingly important. Opting for suppliers who employ eco-friendly manufacturing processes and materials promotes environmental responsibility. But beyond the ecological impact, sustainable practices often reflect a company’s overall commitment to quality and care, fostering a culture of trustworthiness and integrity that resonates throughout their business operations. In conclusion, purchasing a woven wire mesh screen requires a diligent approach that considers materiality, functionality, quality assurance, customization, and logistics. By making informed decisions based on these parameters, businesses and individuals can optimize operational efficiency, reduce costs, and ensure long-term satisfaction with their choice. The expertise and resources provided by reputable suppliers not only elevate the purchasing experience but also establish a dependable foundation for future endeavors.

share

Latest news

-

CE Certified 250 Micron Stainless Steel Mesh | GPT-4 Turbo AI

NewsAug.05,2025

-

CE Certified 250 Micron Stainless Steel Mesh Filter

NewsAug.04,2025

-

Premium Twill Weave Mesh for Industrial Filtration & Strength

NewsAug.03,2025

-

CE Certified 250 Micron Stainless Steel Mesh - Durable Filter

NewsAug.02,2025

-

Screen Mesh Price Deals | gpt-4-turbo Optimized Pricing

NewsAug.01,2025

-

CE Certified 250 Micron Stainless Steel Filter Mesh | Premium

NewsJul.31,2025