Pro . 23, 2024 10:47 Zpět na seznam

Everything You Need to Know About Screening Wire Mesh

When it comes to filtration, safety, or even aesthetic purposes, screening wire mesh plays an essential role in various industries. From industrial applications to household uses, wire mesh screen is a versatile material that provides a wide range of solutions. In this article, we’ll dive into the screen mesh price, the materials commonly used in wire mesh screens, and the advantages of stainless steel wire mesh screens.

What is Screening Wire Mesh?

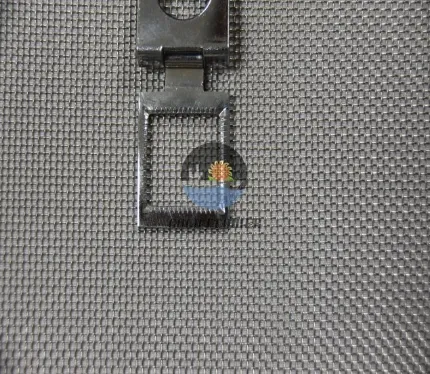

Screening wire mesh is a mesh fabric made from wire strands woven together to create a grid of holes. This mesh can be used in a variety of applications such as filtering, separating materials, providing security, or even as a protective barrier. Depending on its use, the mesh size, wire thickness, and material can vary.

- Drátěná síťovina: This refers to the actual product made from wire strands. The term can encompass a wide range of mesh types, from fine mesh for filtering small particles to coarser mesh used for separating larger materials.

- Screening: The process of using mesh for sorting, filtering, or protecting surfaces from unwanted materials or pests.

Popular Materials for Screening Wire Mesh

Drátěné pletivo z nerezové oceli

One of the most widely used materials in screening wire mesh is stainless steel. Known for its durability and resistance to corrosion, stainless steel wire mesh screens are often used in outdoor applications and industries where hygiene and durability are important.

- Odolnost proti korozi: Stainless steel is highly resistant to rust, making it ideal for harsh outdoor environments or applications that require long-term durability, such as filtration in water treatment or food processing.

- Pevnost a odolnost: The material’s strength makes it suitable for use in demanding applications, from security screens to industrial separation.

- Hygiene: Stainless steel is non-reactive, making it a good choice for environments where food safety and hygiene are essential.

Galvanized Steel Wire Mesh

Galvanized steel is another common material for wire mesh screens. It is coated with a layer of zinc to prevent rust and corrosion, which gives it extra durability and a longer lifespan. This type of wire mesh is often used for applications where cost-effectiveness is a priority, such as in agriculture or construction.

Mosazné drátěné pletivo

Brass wire mesh, although less common than stainless steel, is used in specialized applications where an aesthetically pleasing appearance or specific conductivity properties are required.

Aluminum Wire Mesh

Aluminum wire mesh is lightweight, corrosion-resistant, and relatively inexpensive, making it suitable for use in areas with less rigorous demands, like window screens, ventilation systems, and minor security applications.

Screen Mesh Price: What Affects the Cost?

The screen mesh price depends on a variety of factors, including:

Material Type

- Drátěné pletivo z nerezové ocelitends to be more expensive than galvanized steel or aluminum due to its higher durability and resistance to corrosion.

- Brass or copper wire meshcan also be more expensive, often used in specific or high-end applications.

Mesh Size

The finer the mesh, the higher the price, as smaller holes require more precision and labor to manufacture. Fine meshes are commonly used in filtration or security purposes, while coarser meshes are used in construction or separation.

Wire Thickness

Thicker wires provide stronger and more durable meshes but tend to be more expensive than thinner ones. The price also increases with higher gauge wires used for specific heavy-duty applications.

Quantity

Purchasing in bulk can often reduce the price per unit. Suppliers may offer discounts for larger orders, so businesses often purchase larger rolls of wire mesh to reduce costs.

Customization

Custom-made wire mesh, whether for specific dimensions, coatings, or finishes, will generally cost more than standard pre-manufactured options.

Applications of Screening Wire Mesh

Industrial Filtration and Separation

In industries such as mining, water treatment, and food processing, screening wire mesh plays a critical role in filtering materials, separating solids from liquids, or categorizing materials by size. Stainless steel wire mesh screens are especially popular in these industries due to their ability to withstand harsh chemicals and extreme conditions.

Security and Fencing

Wire mesh screens are also widely used in security applications, including fencing, gates, and barriers. Whether used to protect private property or ensure safety in industrial areas, these meshes provide a durable and cost-effective solution.

Home Use

At home, wire mesh screens are used in window and door screening to keep out insects and pests while allowing air to flow. Stainless steel wire mesh screens are preferred for their strength and ability to maintain airflow without corroding over time.

Construction and Architecture

Wire mesh screens are often used as reinforcement in concrete, or as part of a structural system in buildings. Whether used in slabs, facades, or foundation support, wire mesh is an essential component in modern construction.

Horticulture and Agriculture

In agriculture, screening wire mesh is used in irrigation systems, plant protection, and pest control. It's also used in seed cleaning, grading, and harvesting, where fine mesh is often required.

Choosing the Right Wire Mesh Screen for Your Needs

When choosing a wire mesh screen for your application, consider the following factors:

Purpose

Determine what you need the mesh for—whether it's filtration, protection, security, or aesthetic purposes. The type of material, mesh size, and wire thickness will vary depending on your requirements.

Durability

For outdoor or high-stress applications, drátěné pletivo z nerezové oceli is often the best choice due to its superior strength and corrosion resistance. For less demanding applications, galvanized steel or aluminum mesh may be sufficient.

Mesh Size

Select the appropriate mesh size for your needs. Finer mesh is needed for filtering or screening small particles, while coarser mesh is more appropriate for security or construction.

Price

Compare prices from different suppliers. Consider bulk purchases to lower the overall cost if you need a large quantity. Custom mesh designs may incur additional costs, but they could provide a more tailored solution to your specific needs.

Why Choose Stainless Steel Wire Mesh for Your Screening Needs

In conclusion, screening wire mesh is an essential material used across a variety of industries and home applications. Whether you're looking for stainless steel wire mesh screens for their strength and corrosion resistance, or seeking a more affordable option like galvanized or aluminum wire mesh, there is a product to suit your needs. By understanding the screen mesh price and the factors that influence it, you can make an informed decision about the best mesh for your project. With their wide range of uses in filtration, security, construction, and more, wire mesh screens provide durability, protection, and efficiency for any task.

podíl

-

What Are the Key Applications and Benefits of Chicken Wire Gabion and Related Retaining Solutions?

ZprávyJul.18,2025

-

What Are the Key Advantages and Applications of PVC Coated Gabion Wire Mesh and Related Solutions?

ZprávyJul.18,2025

-

Welded Gabion Mesh Solutions: Strength and Versatility in Construction

ZprávyJul.18,2025

-

Essential Solutions for Slope Stability: A Focus on Protective Nets

ZprávyJul.18,2025

-

Durable Solutions for Erosion Control and Construction: Galvanised Gabion Systems

ZprávyJul.18,2025

-

Constructing Functional Structures: The Art of Making Gabions

ZprávyJul.18,2025