Lis . 21, 2024 22:49 Back to list

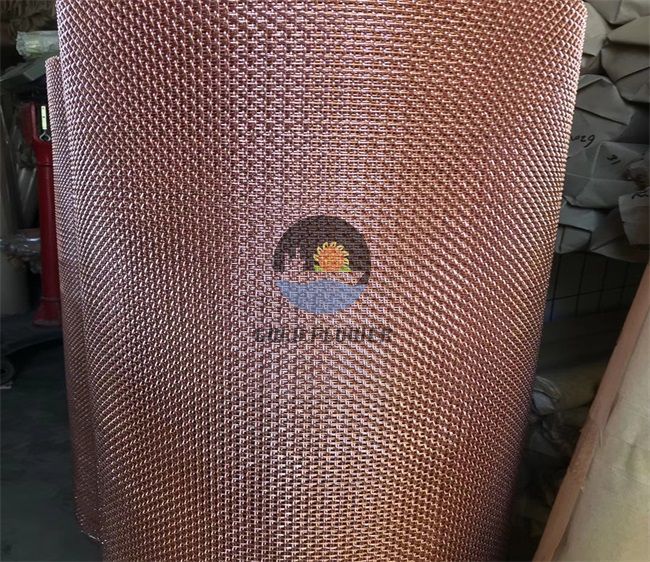

odm wire screens

Understanding ODM Wire Screens Applications and Benefits

In the world of industrial filtration, ODM wire screens have emerged as a preferred choice for many manufacturers and engineers seeking reliable and efficient screening solutions. These screens, made from durable wire materials, offer a range of applications across various sectors, including mining, pharmaceuticals, food processing, and wastewater treatment. This article delves into what ODM wire screens are, their benefits, and how they can enhance operational efficiency.

What Are ODM Wire Screens?

ODM wire screens are specialized filtration products designed to separate solids from liquids or gases effectively. Composed of woven stainless steel or other high-strength wires, these screens are fabricated to meet specific size and shape requirements. The term ODM stands for Original Design Manufacturer, indicating that these screens can be tailored to the unique specifications of different clients. This customization is crucial in ensuring that the screen performs optimally in its intended application.

Key Features of ODM Wire Screens

1. Durability ODM wire screens are crafted from robust materials, making them resistant to wear and tear. This durability ensures a longer lifespan compared to traditional screening methods, reducing the need for frequent replacements.

2. Customizability One of the standout features of ODM wire screens is their adaptability. Manufacturers can adjust parameters such as wire diameter, mesh size, and screen shape to suit the specific requirements of their operations. This level of customization enables optimal performance based on the material being processed.

3. High Flow Rates The design of ODM wire screens facilitates high flow rates, which is particularly important in industries where large volumes of material need to be processed quickly. This efficiency translates to time savings and increased productivity.

odm wire screens

4. Precision Filtration These screens can achieve precise filtration due to their mesh configurations. This precision is essential in applications where maintaining the purity of the end product is crucial, such as in pharmaceuticals and food production.

Applications of ODM Wire Screens

1. Mining In the mining industry, ODM wire screens are used for separating valuable minerals from waste materials. Their high durability and efficiency make them ideal for the rugged conditions typically found in mining sites.

2. Pharmaceuticals The pharmaceutical industry requires stringent standards of cleanliness and precision. ODM wire screens are employed in various stages of manufacturing to ensure that contaminants are removed and that the final products meet regulatory standards.

3. Food Processing In food production, maintaining hygiene and quality is vital. ODM wire screens help in filtering out impurities, ensuring that only the finest ingredients make it to the final product.

4. Wastewater Treatment The treatment of wastewater often involves the removal of solids to maintain environmental standards. ODM wire screens play a significant role in this process, efficiently separating solids from liquids.

Conclusion

In conclusion, ODM wire screens represent a versatile and robust solution for various industrial screening needs. Their customizable nature, combined with durability and efficiency, makes them an essential tool across multiple sectors. As industries continue to evolve and demand better filtration solutions, ODM wire screens are set to play a pivotal role in enhancing operational efficiency and product quality. Investing in these innovative screens not only supports compliance with industry standards but also contributes to long-term cost savings and improved sustainability in filtration processes.

share

-

CE Certified 250 Micron Stainless Steel Mesh Filter

NewsAug.04,2025

-

Premium Twill Weave Mesh for Industrial Filtration & Strength

NewsAug.03,2025

-

CE Certified 250 Micron Stainless Steel Mesh - Durable Filter

NewsAug.02,2025

-

Screen Mesh Price Deals | gpt-4-turbo Optimized Pricing

NewsAug.01,2025

-

CE Certified 250 Micron Stainless Steel Filter Mesh | Premium

NewsJul.31,2025

-

CE Certified 250 Micron Stainless Steel Mesh | Premium Filter

NewsJul.31,2025