Zář . 22, 2024 01:47 Back to list

oem wire mesh 304

The Versatility of OEM 304 Wire Mesh

In the world of industrial and commercial applications, wire mesh plays a crucial role due to its diverse applications and properties. One particular type that stands out is OEM 304 wire mesh. Crafted from high-quality 304 stainless steel, this material possesses excellent corrosion resistance, durability, and versatility, making it an ideal choice for various industries.

Understanding 304 Stainless Steel

Before diving into the specifics of OEM 304 wire mesh, it’s important to understand what 304 stainless steel is. This alloy is composed primarily of iron, chromium (approximately 18%), and nickel (around 8%). The addition of chromium provides an oxide layer that protects against rust and corrosion, while nickel enhances the ductility and workability of the material. This combination makes 304 stainless steel suitable for environments that are challenging and require materials that can withstand extreme conditions.

Key Features of OEM 304 Wire Mesh

1. Corrosion Resistance One of the standout features of OEM 304 wire mesh is its exceptional resistance to corrosion. This property makes it perfect for use in environments that are exposed to chemicals, moisture, and harsh weather conditions, such as in manufacturing plants, marine applications, and agriculture.

2. Durability and Strength The robust nature of 304 stainless steel ensures that the wire mesh maintains its integrity over time, even under physical stress. This durability is particularly beneficial in applications that require heavy-duty support structures, filtration processes, and safety enclosures.

oem wire mesh 304

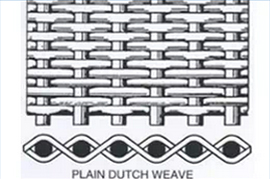

3. Versatile Applications OEM 304 wire mesh is incredibly versatile. It can be used in various applications, including architectural projects for aesthetic paneling, industrial applications for filtration and separation, and safety tools for barriers and fences. Its flexibility in usage allows it to be tailored to specific needs, which is where OEM (Original Equipment Manufacturer) offers a significant advantage.

4. Design and Customization OEM manufacturers can create wire mesh products that cater to specific dimensions, shapes, and performance requirements. This customization is beneficial for businesses looking for unique solutions tailored to their needs, whether in industrial settings, food processing, or even in the construction industry.

Applications Across Industries

The applications of OEM 304 wire mesh span numerous sectors. In the food and beverage industry, it is commonly employed for protecting equipment and ensuring safety standards while also being easy to clean due to its non-reactive nature. In the construction industry, it serves as reinforcement in concrete and as a barrier for safety. Other applications include HVAC systems for air filtration, automotive industries, and electronics for shielding components from electromagnetic interference.

Conclusion

In conclusion, OEM 304 wire mesh is a material that brings exceptional value to various industries due to its impressive properties of corrosion resistance, durability, and versatility. As businesses and industries continue to seek efficient and reliable materials, the demand for OEM 304 wire mesh is expected to rise. Its ability to meet specific requirements and adapt to diverse applications makes it a vital player in modern manufacturing and industrial processes. Companies looking for a dependable solution for their wire mesh needs should consider the advantages that OEM 304 wire mesh offers, ensuring both performance and quality.

share

-

High Flow Water Filter Cartridge – Superior Filtration & Easy Replacement Hi Flow Water Filter Replacement Cartridge & Aqua Flow 50 Filter Cartridges

NewsJul.04,2025

-

Premium Window and Door Mosquito Net – Effective Insect Protection for Your Home

NewsJul.04,2025

-

Premium Stainless Steel Netting Mesh Discount & ODM Stainless Steel Wire Mesh Solutions

NewsJun.24,2025

-

High-Quality Screen Stone for Modern Stone Screen Walls Elegant Facade Solutions

NewsJun.10,2025

-

High Quality Wire Filter – Cheap Stainless Steel Filter Wire Mesh Cloth & Wire Mesh Filter Solutions

NewsJun.10,2025

-

5 Micron Water Filter Cartridge - Premium Sediment Filtration, Universal Fit

NewsJun.10,2025