Lis . 25, 2024 07:02 Back to list

Custom OEM Wire Mesh Solutions for Various Applications and Industries

Understanding OEM Wire Mesh Applications and Benefits

Wire mesh is an integral component in various industries, providing solutions for filtration, separation, and support. Among its many variants, OEM (Original Equipment Manufacturer) wire mesh stands out as a specialized product designed to meet specific requirements of manufacturers. This article explores the characteristics, applications, and advantages of OEM wire mesh.

What is OEM Wire Mesh?

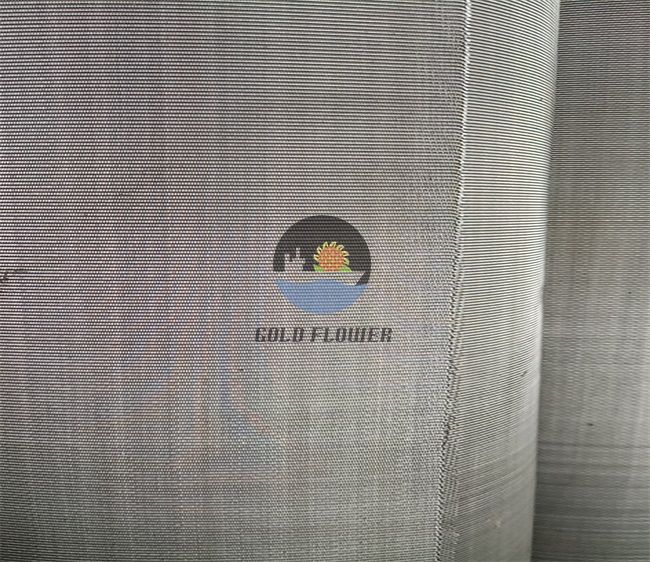

OEM wire mesh refers to custom-designed wire mesh products produced to meet the unique specifications provided by manufacturers. Unlike standard wire mesh, which is mass-produced and meant for general applications, OEM wire mesh is tailored to the needs of a specific project or product. This customization involves adjusting various factors, including material type, mesh size, wire diameter, and treatment processes, ensuring that the final product aligns perfectly with the intended use.

Materials and Construction

OEM wire mesh can be constructed from a variety of materials, including stainless steel, aluminum, fiberglass, and various alloys. Stainless steel is particularly popular due to its strength, durability, and resistance to corrosion, making it suitable for both indoor and outdoor applications. The choice of material is critical, as it affects the mesh's performance, lifespan, and suitability for the intended environment.

The construction of OEM wire mesh also varies significantly. Different weaving techniques such as plain weave, twill weave, and Dutch weave can be employed, depending on the desired characteristics of the final product. For instance, a tighter weave might be required for filtration applications, while a looser weave could be ideal for structural support.

Applications of OEM Wire Mesh

The versatility of OEM wire mesh enables its use across numerous industries. Here are some common applications

1. Filtration and Screening OEM wire mesh is widely used in filtration systems where precise separation is critical. For example, in water treatment plants, OEM wire mesh can be tailored to filter out specific particle sizes, ensuring higher efficiency and effectiveness in the filtration process.

oem wire mesh 5

2. Automotive Industry In the automotive sector, OEM wire mesh is often used in components such as air filters, oil filters, and other critical systems where durability and performance are paramount. Customization allows manufacturers to meet strict regulatory standards while ensuring optimal performance.

3. Construction and Architecture Builders utilize OEM wire mesh for reinforcement in concrete and as a component in walkway grates, fences, and security screens. Its strength and structural integrity make it a preferred choice for enhancing safety and durability in construction projects.

4. Industrial Equipment Many industrial machines benefit from OEM wire mesh used in guards, shields, and protective covers. The tailored specifications ensure that these components effectively protect machinery and personnel while allowing necessary airflow.

5. Food and Beverage Industry In food processing, OEM wire mesh is used for sifting, sorting, and separating materials. It meets the high sanitation standards required in food production while providing long-lasting performance.

Benefits of OEM Wire Mesh

The primary advantage of OEM wire mesh lies in its tailored approach. By conforming to specific requirements, manufacturers can ensure that the mesh performs optimally in its intended application. Customization also allows for improved efficiency, reduced waste, and better resource management, as companies can produce only what they need.

Furthermore, OEM wire mesh often results in enhanced durability and longevity. When mesh is designed to withstand particular environmental conditions or stresses, it reduces the likelihood of failure or replacement, ultimately saving costs in the long run.

Conclusion

OEM wire mesh plays a crucial role in enhancing performance across various industries by providing customized solutions to meet specific needs. Its adaptability and the ability to cater to unique specifications make it an invaluable asset in manufacturing, construction, automotive, and many other fields. As technology advances and industries evolve, the significance of OEM wire mesh will continue to grow, highlighting the importance of tailored solutions in a competitive marketplace.

share

-

Premium CE Certified Metal Fine Mesh for Precision & Safety

NewsAug.24,2025

-

Stainless Steel Wedge Wire Mesh: Durable, Precision Filtration

NewsAug.23,2025

-

CE Certified 250 Micron Stainless Steel Mesh for Precision Filtration

NewsAug.22,2025

-

CE Certified 250 Micron SS Mesh - Precision Filtration & Strength

NewsAug.21,2025

-

CE Certified Woven Wire Mesh Filters | Premium Filtration Solutions

NewsAug.19,2025

-

High-Performance Particle Filters: Optimal Mediums & Applications

NewsAug.18,2025