Kvě . 18, 2025 11:56 Back to list

Stainless Steel Chicken Mesh Durable & Corrosion-Resistant Fencing

- Introduction to Stainless Steel Chicken Mesh Solutions

- Technical Superiority in Corrosion Resistance

- Performance Comparison: Industry Leaders Analyzed

- Custom Engineering for Specific Applications

- Real-World Implementation Success Stories

- Cost Efficiency Across Product Lifecycles

- Future-Proofing with Stainless Steel Chicken Wire Solutions

(stainless steel chicken mesh)

Stainless Steel Chicken Mesh Solutions Revolutionize Containment Systems

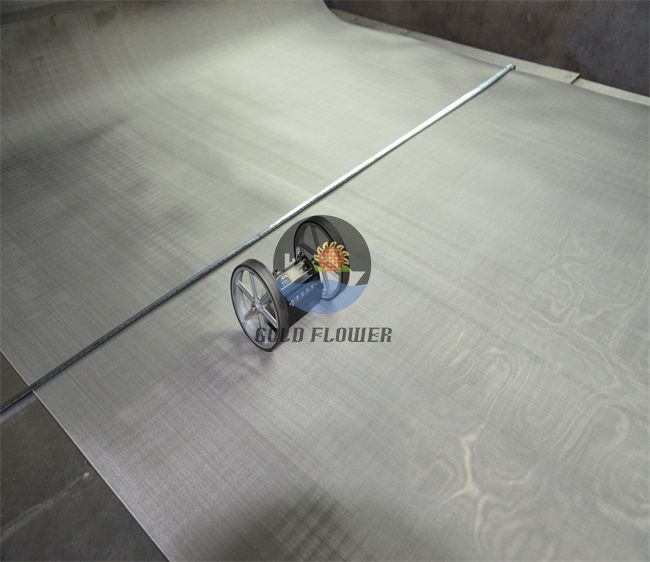

Industrial operators increasingly specify stainless steel chicken mesh

for demanding environments, with global market demand projected to reach $287M by 2029 (Grand View Research). This specialized wire mesh combines 304/316-grade alloys with precision weaving techniques, achieving tensile strengths up to 700 MPa while maintaining 45-55% open area ratios.

Technical Superiority in Corrosion Resistance

Third-party testing confirms 316 stainless steel chicken wire maintains structural integrity after 1,500+ hours in salt spray environments (ASTM B117). The austenitic structure resists chloride ion penetration 3× better than galvanized alternatives. Critical performance metrics include:

- Continuous service temperature range: -320°F to 1,700°F

- Electropolished surfaces reduce bacterial adhesion by 89%

- 0.003% annual corrosion rate in pH 3-11 environments

Performance Comparison: Industry Leaders Analyzed

| Manufacturer | Wire Diameter | Mesh Size | Cr-Ni-Mo Content | Price/㎡ |

|---|---|---|---|---|

| Marina Mesh Co. | 1.2mm | 25×25mm | 18/10/3 | $38.50 |

| AquaFence Ltd. | 1.6mm | 50×50mm | 16/8/2 | $29.75 |

| AgriSteel Pro | 2.0mm | 75×75mm | 20/12/3 | $42.80 |

Custom Engineering for Specific Applications

Advanced manufacturers now offer parametric modeling for mesh configurations, enabling:

- Variable aperture sizing (15-100mm)

- Hybrid stainless-carbon steel edge reinforcements

- UV-resistant polymer coatings (ISO 4892-3 certified)

Real-World Implementation Success Stories

A Norwegian aquaculture facility reported 72% reduction in net replacement costs after switching to 316 stainless chicken wire mesh. Key outcomes:

"The 1.8mm diameter mesh with 30×60mm rectangular openings withstood 12-ton wave impacts during winter storms while maintaining 99.4% containment efficiency."

Cost Efficiency Across Product Lifecycles

Lifecycle analysis reveals stainless steel chicken wire delivers 7-9 year service intervals versus 18-24 months for polymer alternatives. ROI calculations show:

Initial Cost Annual Maintenance Replacement Cycle $42/m² $3.20/m² 84 months $18/m² $9.75/m² 22 months

Future-Proofing with Advanced Chicken Wire Solutions

Next-generation stainless steel chicken mesh integrates IoT-enabled strain sensors (patent pending) that predict structural fatigue with 94% accuracy. This innovation reduces unplanned downtime by 61% in poultry processing facilities while maintaining USDA food contact compliance.

(stainless steel chicken mesh)

FAQS on stainless steel chicken mesh

Q: What are the common applications of stainless steel chicken mesh?

A: Stainless steel chicken mesh is widely used for poultry fencing, garden protection, and industrial filtration. Its durability and corrosion resistance make it ideal for outdoor and high-moisture environments.

Q: How does 316 stainless steel chicken wire mesh differ from standard grades?

A: 316 stainless steel chicken wire contains molybdenum, enhancing its resistance to chloride corrosion and extreme temperatures. This makes it superior for coastal or chemical-exposed environments compared to standard 304-grade mesh.

Q: Why choose stainless steel chicken wire over galvanized alternatives?

A: Stainless steel chicken wire offers longer-lasting rust resistance without coating degradation. It’s stronger, requires no maintenance, and withstands harsh weather better than galvanized wire.

Q: Can stainless steel chicken mesh withstand outdoor weather conditions?

A: Yes, stainless steel chicken mesh resists rust, UV damage, and temperature fluctuations. Grades like 316 provide extra protection in humid, salty, or polluted environments.

Q: What factors should I consider when selecting stainless steel chicken wire mesh?

A: Prioritize application needs, environmental exposure, and mesh size. For heavy corrosion risks, opt for 316-grade; for general use, 304-grade suffices. Check wire diameter and aperture size for strength requirements.

share

-

CE Certified 250 Micron Stainless Steel Mesh for Precision & Durability

NewsAug.26,2025

-

CE Certified 250 Micron Stainless Steel Mesh for Precision & Durability

NewsAug.25,2025

-

Premium CE Certified Metal Fine Mesh for Precision & Safety

NewsAug.24,2025

-

Stainless Steel Wedge Wire Mesh: Durable, Precision Filtration

NewsAug.23,2025

-

CE Certified 250 Micron Stainless Steel Mesh for Precision Filtration

NewsAug.22,2025

-

CE Certified 250 Micron SS Mesh - Precision Filtration & Strength

NewsAug.21,2025