Pro . 15, 2024 07:42 Back to list

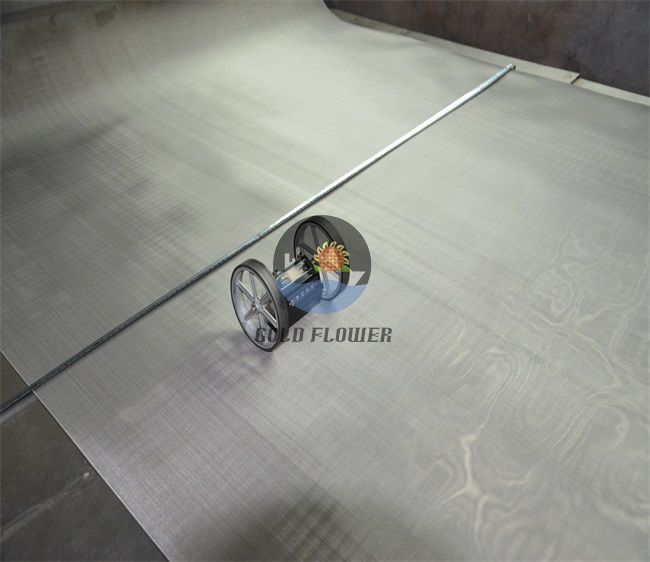

stainless steel metal mesh

Stainless Steel Metal Mesh Versatility and Applications

Stainless steel metal mesh has emerged as a vital component in numerous industries, owing to its unmatched durability, corrosion resistance, and versatility. Made from a blend of steel and chromium, stainless steel retains its integrity and appearance over time, making it an ideal choice for a variety of applications. This article explores the distinct properties of stainless steel metal mesh, its manufacturing process, and the various sectors where it finds practical use.

Properties of Stainless Steel Metal Mesh

Stainless steel metal mesh is renowned for its exceptional corrosion resistance, which makes it suitable for use in harsh environments. The presence of chromium in its composition forms a protective layer on the surface, preventing rust and oxidation. This characteristic is especially beneficial in industries like pharmaceuticals, food processing, and marine applications, where equipment and materials are constantly exposed to moisture and corrosive substances.

Additionally, stainless steel mesh boasts high tensile strength, enabling it to withstand significant stress without deforming. This durability is crucial in applications where mechanical strength is required, such as architectural frameworks, automotive grilles, and industrial sieving processes.

Another noteworthy property is its aesthetic appeal. The shiny, polished look of stainless steel adds a modern touch to architectural designs and features. As a result, stainless steel mesh is frequently used in interior and exterior design elements, contributing not only to functionality but also to the overall aesthetic of a space.

Manufacturing Process

The production of stainless steel metal mesh involves several key steps, ensuring the final product meets specific standards. The process begins with the selection of high-quality stainless steel alloys. These materials are then drawn into wire, which can vary in diameter depending on the intended application.

Once the wire is produced, it is woven or welded to create a mesh. The weaving methods include plain weave, twill weave, and Dutch weave, each offering different characteristics suitable for diverse applications. For instance, the plain weave is often used for filtration, while the twill weave provides additional strength and flexibility.

After weaving or welding, the stainless steel mesh undergoes finishing treatments. These may include polishing, passivation, or coating to enhance its resistance to rust and improve its appearance. The finished product is then inspected to ensure it adheres to industry standards before being distributed to various sectors.

stainless steel metal mesh

Applications of Stainless Steel Metal Mesh

Stainless steel metal mesh is incredibly versatile, with applications spanning multiple industries

1. Architecture and Design In modern architecture, stainless steel mesh is employed in facades, partitions, and decorative elements. Its combination of strength and aesthetic appeal makes it an excellent choice for contemporary design projects.

2. Industrial Use In manufacturing and processing plants, stainless steel mesh is commonly utilized for filtration, sieving, and screening applications. It effectively separates materials, whether in food production or chemical processing, ensuring that only the desired products proceed through various stages of production.

3. Construction In the construction industry, stainless steel mesh is used in reinforcing concrete structures. Its high tensile strength enhances the structural integrity of buildings, bridges, and other constructions, while also preventing cracking and deformation over time.

4. Automotive Automotive manufacturers employ stainless steel mesh for grilles and other components due to its durability and resistance to corrosion. This not only contributes to the vehicle's performance but also its aesthetic appeal.

5. Aerospace and Marine Given its resilience in extreme environments, stainless steel mesh is used in aerospace components and marine applications. Whether in aircraft interiors or shipbuilding, its properties ensure continued performance and safety.

6. Food and Beverage Industry The food industry relies on stainless steel mesh for everything from brewing to cooking, as it meets strict hygiene standards. Its corrosion resistance makes it suitable for contact with various food substances without compromising quality or safety.

Conclusion

In summary, stainless steel metal mesh is a remarkable product that provides numerous benefits across multiple industries. Its durability, corrosion resistance, and aesthetic qualities make it a favored choice for many applications, ranging from architectural designs to industrial processes. As technology advances, the potential uses for stainless steel mesh continue to expand, solidifying its place as a fundamental element in both manufacturing and design. Whether in everyday products or specialized applications, stainless steel metal mesh stands as a testament to the enduring appeal and functionality of stainless steel.

share

-

CE Certified 250 Micron Stainless Steel Mesh for Precision Filtration

NewsAug.22,2025

-

CE Certified 250 Micron SS Mesh - Precision Filtration & Strength

NewsAug.21,2025

-

CE Certified Woven Wire Mesh Filters | Premium Filtration Solutions

NewsAug.19,2025

-

High-Performance Particle Filters: Optimal Mediums & Applications

NewsAug.18,2025

-

Competitive Screen Mesh Price | 1/4", 1/8", 1/2" Wire Mesh Screens

NewsAug.17,2025

-

CE Certified 250 Micron SS Mesh: Precision & Durability

NewsAug.15,2025