nov . 28, 2024 13:12 Back to list

High-Quality Fine Mesh Screens for Effective Filtration and Separation Solutions

High-Quality Fine Mesh Screening An Essential Tool for Various Industries

In a world where efficiency and precision are paramount, high-quality fine mesh screening has emerged as an essential tool across various industries. Whether in food processing, pharmaceuticals, wastewater treatment, or chemical manufacturing, the importance of fine mesh systems cannot be overstated. These screens serve the crucial function of separating particles based on size, ensuring product purity, enhancing operational efficiency, and meeting regulatory compliance.

What is Fine Mesh Screening?

Fine mesh screening refers to the process of using a mesh material with small openings to filter and separate substances. The mesh can be made from various materials, including stainless steel, nylon, and polyester, and its quality plays a critical role in the efficiency of the separation process. The term fine typically indicates that the mesh has an opening size of less than 1 millimeter, allowing for the precise filtering of fine particles, liquids, and slurries.

Applications of Fine Mesh Screening

1. Food Processing

In food processing, high-quality fine mesh screens are crucial for maintaining hygiene and ensuring product quality. They are used to filter out impurities from raw materials, ensuring that only the best quality ingredients are used in food production. For instance, sieving flour or sugar through a fine mesh screen removes unwanted lumps and contaminants, resulting in a smoother final product. Additionally, in the production of beverages, fine mesh screens help in clarifying juices and brewing processes, ensuring a crisp and clean finish.

2. Pharmaceutical Industry

The pharmaceutical industry demands the highest standards of purity and precision. Fine mesh screening is vital in this sector for processes like granulation, tablet production, and ingredient purification. By using fine mesh screens, pharmaceutical companies can remove contaminants, ensure uniformity in particle size, and adhere to stringent regulatory requirements. A reliable mesh screening system helps to prevent cross-contamination and guarantees that products are safe for consumer use.

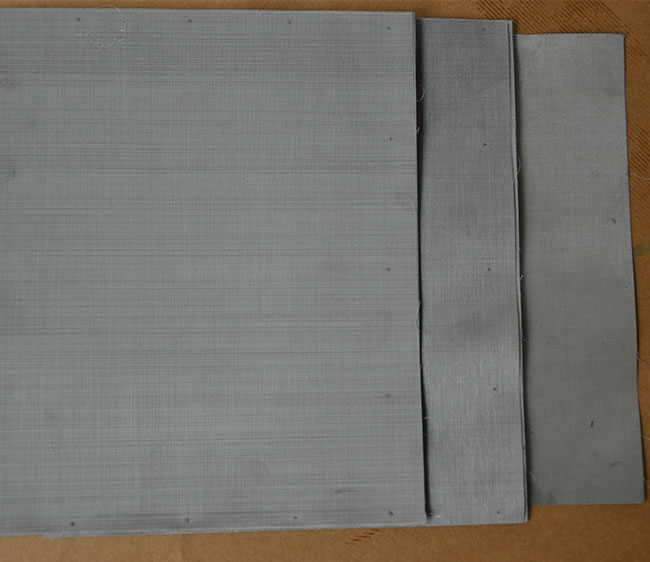

high quality fine mesh screening

In wastewater treatment, fine mesh screening plays a pivotal role in removing solids and debris from liquid waste before it undergoes further processing. By employing high-quality fine mesh screens, treatment facilities can enhance the efficiency of the treatment process, protect equipment from wear and tear, and ensure that the treated water meets environmental standards. Proper filtration reduces the load on subsequent treatment processes, making the overall system more effective and sustainable.

4. Chemical Manufacturing

The chemical manufacturing sector utilizes fine mesh screening to separate different components during the production process. The screens allow for precise filtering of substances, ensuring that mixtures are of the desired consistency and purity. This is particularly important in the production of specialty chemicals, where even minor impurities can significantly affect the performance and safety of the final product.

Benefits of High-Quality Fine Mesh Screens

Investing in high-quality fine mesh screening systems offers numerous benefits

- Enhanced Product Quality By effectively removing unwanted particles and contaminants, fine mesh screens help improve the overall quality of products across industries. - Increased Efficiency High-quality screens facilitate more efficient processing, reducing bottlenecks and enhancing production rates.

- Regulatory Compliance Many industries are governed by strict regulations regarding product purity and safety. Fine mesh screening helps businesses meet these standards, avoiding costly penalties and ensuring consumer safety.

- Cost-Effectiveness Although initial investment may be higher for high-quality screens, their durability and effectiveness can lead to significant cost savings in the long run by reducing waste and minimizing downtime.

Conclusion

In conclusion, high-quality fine mesh screening is an invaluable tool that spans multiple industries. From food processing to pharmaceuticals to wastewater treatment, the role of fine mesh screens cannot be overlooked. Their ability to enhance product quality, improve operational efficiency, and ensure compliance with regulations makes them an essential component in modern industrial processes. As industries continue to evolve and demand higher standards, investing in quality screening solutions will become increasingly critical for businesses striving for excellence.

share

-

CE Certified 250 Micron Stainless Steel Mesh Filter

NewsAug.04,2025

-

Premium Twill Weave Mesh for Industrial Filtration & Strength

NewsAug.03,2025

-

CE Certified 250 Micron Stainless Steel Mesh - Durable Filter

NewsAug.02,2025

-

CE Certified 250 Micron Stainless Steel Filter Mesh | Premium

NewsJul.31,2025

-

CE Certified 250 Micron Stainless Steel Mesh | Premium Filter

NewsJul.31,2025

-

CE Certification Buy Wire Mesh Fence for High Security and Durability

NewsJul.30,2025