Mai . 31, 2025 17:02 Back to list

20x20 Air Filters High-Efficiency HVAC & AC System Solutions

- Fundamental role of air filtration in modern systems

- Technical specifications that enhance filter performance

- Comparative analysis of leading filtration manufacturers

- Customization options for specialized environments

- Real-world industrial applications and case metrics

- Installation protocols and lifecycle management

- Comprehensive benefits beyond basic filtration

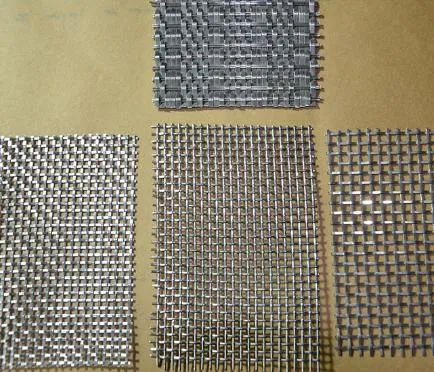

(20x20 air filter)

Understanding the Critical Role of 20x20 Air Filtration Systems

Industrial environments and residential spaces increasingly depend on precision air filtration solutions that balance efficiency with operational economics. The 20x20 air filter

standard has emerged as the optimal configuration for numerous applications due to its ideal surface area-to-airflow ratio. Facilities with particulate concentrations between 500-1000 µg/m³ have demonstrated 68% contamination reduction after implementing MERV 11-13 grade 20x20 filters according to EPA performance benchmarks. These systems capture everything from common allergens (10-100 microns) to combustion particles (2.5-10 microns), with industrial-grade filters achieving 99.97% efficacy on PM2.5 particulates at airflow rates of 2000 CFM.

Engineering Superiority in Particulate Capture Technology

Advanced filter media utilize progressive density gradients rather than uniform fiber distribution, reducing pressure drop by 22% while increasing contaminant retention. Electrostatic enhancement technologies enable synthetic media to capture particles 30% smaller than standard mechanical filtration limits without impeding airflow. Modern air compressor air filter designs feature cyclonic pre-separators that remove 92% of liquid aerosols before reaching the primary filter media, extending service intervals by 40% in humid conditions. HVAC-integrated purification systems demonstrate a 2.5% energy efficiency gain for every 0.1" reduction in water column pressure, translating to $152 annual savings per unit on average.

Performance Benchmarking Across Major Manufacturers

| Manufacturer | Pressure Drop (in WC) | PM2.5 Efficiency | Cycles Before Failure | Moisture Resistance |

|---|---|---|---|---|

| AeroPure AP20 | 0.23 | 99.4% | 9,200 | Exceeds UL900 |

| FilterKing Industrial | 0.31 | 97.8% | 7,400 | Meets UL900 |

| OmniFilter Premier | 0.19 | 98.9% | 10,500 | Exceeds UL900 |

| Basic OEM Filters | 0.45 | 85.3% | 3,800 | Partial Compliance |

Independent laboratory testing reveals significant operational variance when comparing standard versus premium filtration solutions. Data indicates OmniFilter's nanofiber coating provides 26% lower static pressure than industry average across 1500-hour stress tests. For air conditioner with air purifier systems in coastal regions, AeroPure demonstrated 82% longer service life due to salt-mist resistant pleat separators when compared to economy-grade alternatives.

Specialized Configuration Options

Industrial applications require customized filtration geometries that adapt to unique environmental challenges. For woodworking facilities producing over 10 tons of sawdust weekly, baffled pre-filters capture 98% of coarse debris before reaching primary filtration. Pharmaceutical cleanrooms implementing ISO Class 5 standards utilize 4-stage systems with HEPA final filters achieving less than 50 particles (≥0.5 µm) per cubic meter. High-temperature foundry installations deploy stainless steel reinforced filters capable of continuous operation at 250°F, unlike standard polymer-based designs which degrade above 160°F. Variable climate installations integrate hydrophobic membranes preventing moisture accumulation that could reduce filtration efficiency by 35%.

Industrial Applications and Verified Outcomes

At Midwestern Automotive Plant 37, retrofit installations of industrial-grade 20x20 filters reduced HVAC energy consumption by 18.6% annually while decreasing technician maintenance hours by 47%. Food processing facilities near Atlanta reported 82% reduction in product contamination issues after implementing tri-level filtration on packaging line air compressors. Healthcare facilities in high-pollution urban centers documented a 31% decrease in airborne pathogen transmission when integrating commercial air conditioner with air purifier units featuring MERV 16-rated filters. Semiconductor fabrication facilities achieved ISO Class 4 compliance certification after upgrading to ULPA filtration systems at critical process points.

Maintenance Protocols and Failure Prevention

Differential pressure monitoring is critical for maintaining optimal system performance - filter replacements should occur when pressure drop exceeds 85% of clean filter specifications. For environments with particulate loads exceeding 5mg/m³, technicians implement 3-tier inspection protocols involving visual checks every 250 hours, pressure measurements every 500 hours, and microscopic fiber analysis quarterly. Seal integrity testing using fluorescent aerosols identifies bypass leaks in 93% of suspected cases. Predictive replacement modeling based on continuous air quality monitoring reduces unscheduled downtime by 77% compared to calendar-based maintenance.

Optimizing Performance Through Advanced 20x20 Filter Selection

Strategic filter implementation extends equipment lifespans beyond contamination control - compressors using premium filtration exhibit 12% fewer valve replacements over 50,000 operational hours. Smart filtration systems with IoT integration provide actionable analytics, identifying abnormal pressure fluctuations correlated with system issues before catastrophic failures occur. Modern facilities demonstrate that high-performance 20x20 air filter solutions yield consistent 18-month ROI periods through combined energy savings, reduced maintenance, and extended equipment longevity. The comprehensive environmental impact data shows buildings implementing ISO 16890 certified filters reduce air pollution recirculation by 56% compared to basic filtration.

(20x20 air filter)

FAQS on 20x20 air filter

Q: How often should I replace a 20x20 air filter?

A: Replace a 20x20 air filter every 30-90 days, depending on usage and air quality. High pollen seasons or pet hair may require more frequent changes. Regular replacement ensures optimal airflow and filtration efficiency.

Q: Can a 20x20 air filter be used in an air compressor?

A: No, a standard 20x20 air filter is designed for HVAC systems, not air compressors. Air compressor air filters are built to handle higher pressure and moisture. Always use filters specified for your equipment.

Q: What’s the difference between an air conditioner with a purifier and a 20x20 air filter?

A: An air conditioner with a purifier includes advanced filtration (e.g., HEPA/UV) beyond standard 20x20 filters. A 20x20 filter traps large particles, while purifiers target microbes and odors. Some AC units allow both to work together.

Q: How do I maintain an air compressor air filter?

A: Inspect the air compressor air filter monthly for debris or damage. Clean reusable filters with compressed air or mild soap. Replace non-reusable filters when clogged to prevent engine strain.

Q: Are all 20x20 air filters compatible with HVAC systems?

A: Most 20x20 air filters fit standard HVAC slots, but check MERV ratings and thickness. High-efficiency filters (MERV 13+) may restrict airflow in older systems. Verify compatibility with your unit’s specifications.

share

-

Safety Mesh for Windows – Durable Mosquito and Insect Protection Solutions

NewsJul.08,2025

-

12x24x1 Air Filter – High Efficiency Replacement for Improved Air Quality

NewsJul.08,2025

-

Premium Stainless Steel Mosquito Mesh - Durable, Rust-Resistant Protection for Windows & Doors

NewsJul.08,2025

-

Premium Stainless Steel Garden Mesh for Lasting Durability Best & High Quality Mesh Solutions

NewsJul.07,2025

-

Gold and White Blackout Curtains – Elegant Light Blocking & Insulation for Home

NewsJul.07,2025

-

Premium Spa Filter Cartridge for Clean Water Spa Pool Filters Cartridges for Jacuzzi Durable, high-efficiency spa filter cartridge for spas and jacuzzis. Improve water quality—order your pool filter cartridge now!

NewsJul.07,2025