Feb . 07, 2025 05:36 Back to list

Hot Dipped Galvanized Gabion

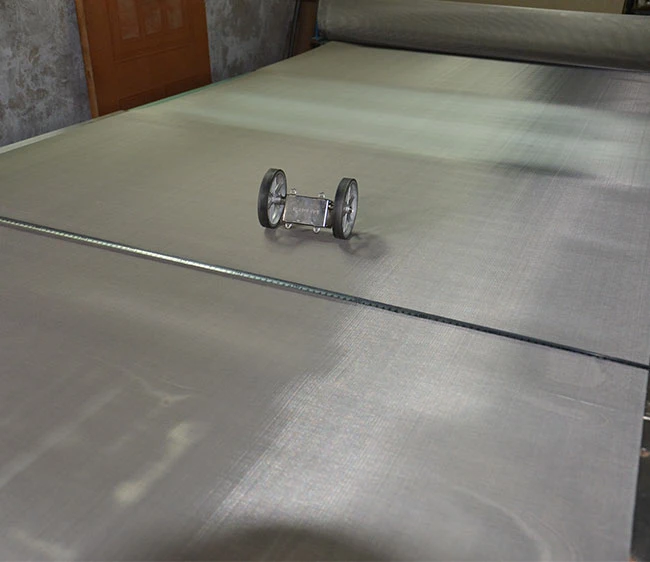

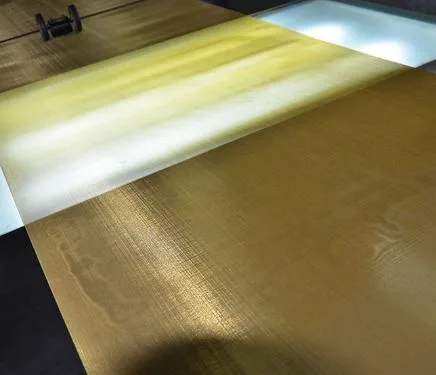

Investing in a gabion wire mesh machine offers a strategic advantage for businesses looking to enhance their production capabilities in the construction and landscaping industries. Gabion structures, owing to their durability and versatility, are increasingly employed in projects ranging from erosion control and slope stabilization to decorative landscaping elements. Understanding the intricacies of gabion wire mesh production requires an exploration of the machine's design, functionality, and the benefits it brings to operations.

Building trustworthiness in the gabion wire mesh machine investment involves comprehensive after-sales service and technical support. Reliable manufacturers offer warranties and maintenance services, ensuring prolonged machine life and consistent operation. Training programs for operators can enhance machine efficiency and ensure safe operation, which is critical for maintaining workplace safety standards. Notably, the financial implications of investing in a gabion wire mesh machine should be aligned with the anticipated return on investment. These machines, despite their upfront costs, can lead to substantial savings in the long term by fostering in-house production capabilities and reducing dependency on external suppliers. Additionally, optimized production processes can open avenues for businesses to explore custom gabion orders, thereby expanding their market reach. For those considering such an investment, visiting existing installations and seeking demonstrations can provide practical insights into machine operation and performance. By engaging with a network of industry professionals and forums, potential buyers can gauge real-world experiences and gather reviews that further inform their purchasing decisions. In summary, a gabion wire mesh machine stands as a pivotal investment for companies in the construction and landscaping sectors. Its ability to produce diverse, high-quality wire meshes offers both operational efficiency and market competitiveness. With a focus on expertise, quality assurance, and reliable support services, businesses can leverage this technology to not only meet but exceed the growing demands of infrastructure development.

Building trustworthiness in the gabion wire mesh machine investment involves comprehensive after-sales service and technical support. Reliable manufacturers offer warranties and maintenance services, ensuring prolonged machine life and consistent operation. Training programs for operators can enhance machine efficiency and ensure safe operation, which is critical for maintaining workplace safety standards. Notably, the financial implications of investing in a gabion wire mesh machine should be aligned with the anticipated return on investment. These machines, despite their upfront costs, can lead to substantial savings in the long term by fostering in-house production capabilities and reducing dependency on external suppliers. Additionally, optimized production processes can open avenues for businesses to explore custom gabion orders, thereby expanding their market reach. For those considering such an investment, visiting existing installations and seeking demonstrations can provide practical insights into machine operation and performance. By engaging with a network of industry professionals and forums, potential buyers can gauge real-world experiences and gather reviews that further inform their purchasing decisions. In summary, a gabion wire mesh machine stands as a pivotal investment for companies in the construction and landscaping sectors. Its ability to produce diverse, high-quality wire meshes offers both operational efficiency and market competitiveness. With a focus on expertise, quality assurance, and reliable support services, businesses can leverage this technology to not only meet but exceed the growing demands of infrastructure development.

share

Next:

Latest news

-

CE Certified 250 Micron Stainless Steel Mesh Filter

NewsAug.04,2025

-

Premium Twill Weave Mesh for Industrial Filtration & Strength

NewsAug.03,2025

-

CE Certified 250 Micron Stainless Steel Mesh - Durable Filter

NewsAug.02,2025

-

Screen Mesh Price Deals | gpt-4-turbo Optimized Pricing

NewsAug.01,2025

-

CE Certified 250 Micron Stainless Steel Filter Mesh | Premium

NewsJul.31,2025

-

CE Certified 250 Micron Stainless Steel Mesh | Premium Filter

NewsJul.31,2025