Dez . 19, 2024 00:54 Back to list

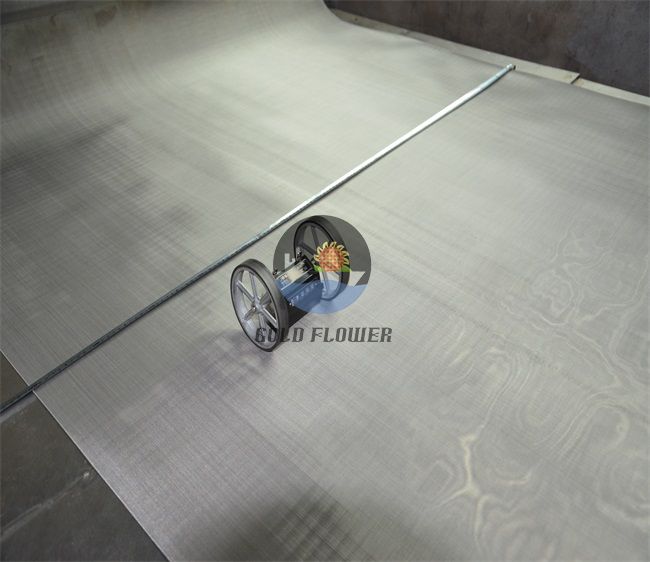

buy stainless steel wire mesh making machine

Buy Stainless Steel Wire Mesh Making Machine A Comprehensive Guide

In the modern industrial landscape, the demand for durable and reliable materials is ever-growing. Among these, stainless steel wire mesh has garnered significant attention due to its versatility and resilience. As businesses look to enhance production capabilities, investing in a stainless steel wire mesh making machine has become increasingly popular. This article provides an insightful overview of the factors to consider when buying such a machine.

Understanding Stainless Steel Wire Mesh

Stainless steel wire mesh is widely used across various industries, including construction, filtration, automotive, agriculture, and food processing. Its resistance to corrosion, high strength, and ability to withstand extreme temperatures make it an ideal material for many applications. Consequently, the need for efficient production machinery has surged, prompting many entrepreneurs to explore options for purchasing a stainless steel wire mesh making machine.

Key Features to Consider

When considering the purchase of a stainless steel wire mesh making machine, several critical features must be evaluated

1. Production Capacity Assess your business needs and look for a machine that can meet your production requirements. Machines are available in various capacities, so choose one that aligns with your operational goals and market demands.

2. Wire Diameter and Mesh Size Different applications require different wire diameters and mesh sizes. Ensure the machine can accommodate a range of specifications to provide flexibility in your product offerings.

3. Automation Level Machines can be fully automatic, semi-automatic, or manual. Automatic machines tend to have higher output and efficiency but may come with a higher price tag. Evaluate the level of automation that suits your workforce and production environment.

buy stainless steel wire mesh making machine

4. Material Quality The quality of the materials used in the machine's construction will impact its durability and maintenance needs. Look for machines constructed from high-quality steel and components that are designed to withstand rigorous operation.

5. Technology Integration Advanced machines may feature digital controls, allowing for easier operation and monitoring. Consider investing in technology that enhances the efficiency and accuracy of the production process.

Cost Considerations

The price of a stainless steel wire mesh making machine varies significantly based on its features, brand, and production capacity. While it may be tempting to choose the least expensive option, it is crucial to weigh the long-term benefits and potential return on investment (ROI). A higher initial cost could lead to greater efficiency, reduced downtime, and higher-quality output, ultimately saving money in the long run.

Supplier Reputation

When purchasing machinery, supplier reputation is as important as the machine itself. Conduct thorough research to find suppliers with a proven track record in the industry. Look for customer reviews, and testimonials, and consider the level of customer service provided. Reliable suppliers often offer warranties and support services, ensuring peace of mind with your investment.

Conclusion

Investing in a stainless steel wire mesh making machine can significantly enhance your production capabilities and contribute to the growth of your business. By considering production capacity, material quality, cost, and supplier reputation, you can make an informed decision that aligns with your operational needs. As the demand for stainless steel wire mesh continues to rise, equipping your business with the right machinery will position you for success in a competitive market.

share

-

Screen Mesh Price Deals | gpt-4-turbo Optimized Pricing

NewsAug.01,2025

-

CE Certified 250 Micron Stainless Steel Filter Mesh | Premium

NewsJul.31,2025

-

CE Certified 250 Micron Stainless Steel Mesh | Premium Filter

NewsJul.31,2025

-

CE Certification Buy Wire Mesh Fence for High Security and Durability

NewsJul.30,2025

-

Stainless Steel Mesh Filter Discs for Precise Filtration Solutions

NewsJul.29,2025

-

CE Certification 250 Micron Stainless Steel Mesh for Industrial Use

NewsJul.29,2025