nov . 10, 2024 11:23 Back to list

Top ASTM Wire Mesh Options for Your Projects and Applications

Exploring the Best ASTM Wire Mesh A Comprehensive Guide

Wire mesh has become an essential material across various industries, primarily due to its durability, strength, and versatility. Among the numerous standards that govern the production of wire mesh, the American Society for Testing and Materials (ASTM) has established a reputation for providing high-quality guidelines. This article delves into the characteristics, types, and applications of the best ASTM wire mesh available in the market today.

Understanding ASTM Wire Mesh Standards

ASTM standards are sets of criteria established to ensure reliability and consistency in materials, processes, and services. ASTM wire mesh is manufactured following these specific standards, which cover aspects such as material quality, dimensions, mechanical properties, and performance. Common ASTM standards relevant to wire mesh include ASTM A185, which pertains to the specifications for welded wire reinforcement, and ASTM A497, which covers the requirements for expanded metal lath. These standards serve as benchmarks, assuring consumers and manufacturers that the products meet rigorous safety and quality specifications.

Types of ASTM Wire Mesh

There are various types of wire mesh compliant with ASTM standards, each suited for specific applications. Some of the most common types include

1. Welded Wire Mesh This type is formed by welding steel wires together at their intersections, creating a grid-like pattern. It is widely used in construction for reinforcing concrete due to its strength and stability. ASTM A185 outlines the specifications for welded wire fabric, ensuring that it meets rigorous performance standards.

2. Expanded Metal Mesh Made from a single sheet of metal that is cut and stretched to create a mesh-like structure, expanded metal is known for its excellent ventilation properties and aesthetic appeal. ASTM A497 specifies the requirements for expanded metal lath, which is often used in drywall and plaster applications.

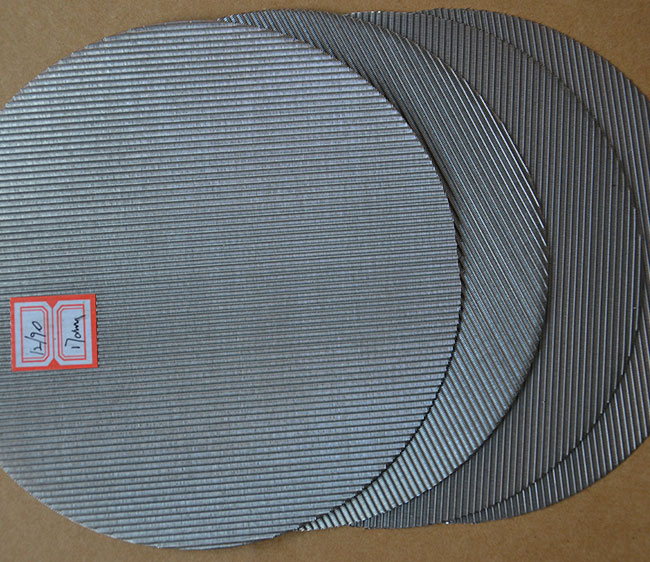

best astm wire mesh

3. Chain Link Fencing Common in security applications, chain link fencing is made from interlocking steel wire strands. Its ASTM specifications cover various factors such as wire gauge, coating, and mesh size, making it a trusted choice for both residential and commercial properties.

4. Intricate Mesh Designs This includes decorative and specialized meshes used in architecture and design. While some may not have a direct ASTM standard, many manufacturers still adhere to quality assurance practices inspired by ASTM criteria.

Applications of ASTM Wire Mesh

The applications of ASTM wire mesh are extensive, spanning multiple industries

- Construction Used for reinforcement in slabs, walls, and foundations, ensuring structural integrity and longevity. - Security Chain link fences and enclosures provide safety and security around properties, schools, and industrial sites. - Agriculture Wire mesh is utilized for animal enclosures, trellises, and crop protection. - Manufacturing Various industrial applications require wire mesh for filtration, sieving, or as part of machinery. - Home Improvement Wire mesh can be found in decorative elements like railings, screens, and garden fencing, offering both utility and aesthetic appeal.

Choosing the Best ASTM Wire Mesh

When selecting wire mesh, it is essential to consider factors such as material type, mesh size, and the specific ASTM standard it adheres to. Not all wire meshes are created equal; therefore, understanding the requirements of your project and choosing the appropriate type is crucial.

In summary, ASTM wire mesh is a robust and reliable material that caters to a myriad of applications. By adhering to stringent standards, manufacturers ensure that the wire mesh available in the market meets high-performance levels. Whether for construction, security, or agriculture, the best ASTM wire mesh offers unparalleled strength and versatility, making it an invaluable resource across various sectors. When making a selection, always consult the relevant ASTM standards and choose a reputable supplier to ensure quality and reliability.

share

-

CE Certified 250 Micron Stainless Steel Mesh - High Durability & CE Approved

NewsJul.21,2025

-

Premium Slope Collapse Protection Mesh | Durable & Effective

NewsJul.20,2025

-

Safety Mesh for Windows – Durable Mosquito and Insect Protection Solutions

NewsJul.08,2025

-

12x24x1 Air Filter – High Efficiency Replacement for Improved Air Quality

NewsJul.08,2025

-

Premium Stainless Steel Mosquito Mesh - Durable, Rust-Resistant Protection for Windows & Doors

NewsJul.08,2025

-

Premium Stainless Steel Garden Mesh for Lasting Durability Best & High Quality Mesh Solutions

NewsJul.07,2025