nov . 26, 2024 02:11 Back to list

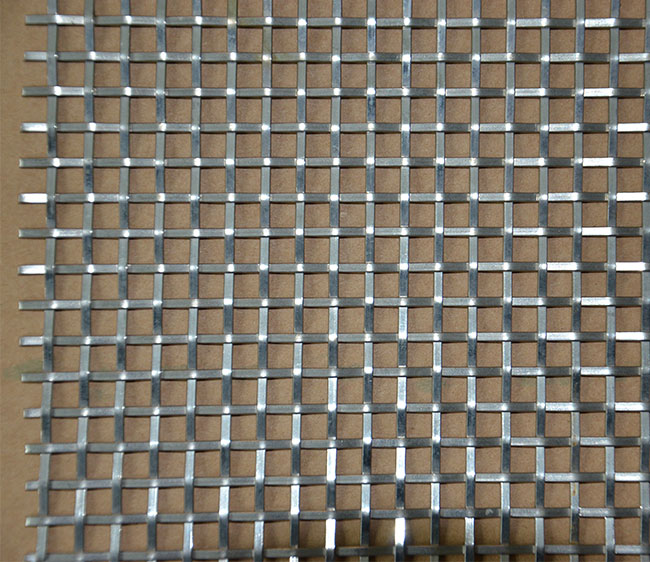

High-Quality Stainless Steel Woven Wire Mesh for Versatile Applications

The Versatility and Utility of Best Stainless Steel Woven Wire Fabric Mesh

Stainless steel woven wire fabric mesh has emerged as an indispensable material across various industries due to its exceptional durability, resistance to corrosion, and versatility in design. This type of mesh, constructed from high-quality stainless steel wires, offers a perfect combination of strength and aesthetic appeal, making it an ideal choice for numerous applications ranging from architecture to filtration processes.

Composition and Properties

The main allure of stainless steel woven wire mesh lies in its composition. Made primarily from stainless steel alloys, typically 304 or 316, this mesh exhibits remarkable resistance to rust and oxidation, making it ideal for environments that may otherwise cause degradation in lesser materials. The inclusion of chromium and nickel in these alloys enhances the mesh's strength while providing a polished finish that remains visually appealing over time.

The woven structure of the mesh contributes to its flexibility and strength. Unlike solid sheets of metal, the woven wire configuration allows for a degree of give and elasticity, which can be beneficial in applications that require some level of adaptability. Furthermore, the mesh can be tailored to specific needs by varying the wire diameter and the size of the openings, providing a bespoke solution to meet various filtrations or architectural demands.

Applications Across Industries

Stainless steel woven wire fabric mesh has found widespread use across numerous sectors. In architectural applications, it is frequently employed as a decorative element in building facades and as safety barriers. The aesthetic flexibility of the mesh allows architects to incorporate it into modern building designs, creating visually striking patterns while maintaining visibility and airflow.

best stainless steel woven wire fabric mesh

In the manufacturing sector, this mesh plays a crucial role in filtration and separation processes

. Industries reliant on precision filtration, such as food processing, pharmaceuticals, and chemicals, utilize stainless steel woven wire mesh for its superior filtering capabilities. This mesh serves to filter out particulates while ensuring that the desired materials remain unimpeded, thereby optimizing production efficiency.The automotive industry also benefits from stainless steel woven wire fabric mesh in applications such as exhaust systems and engine compartments, where heat resistance and durability are paramount. Additionally, it is increasingly used in the design of outdoor structures, including fencing and shading solutions, due to its strength and weather resistance.

Maintenance and Longevity

One of the significant advantages of stainless steel woven wire fabric mesh is its low maintenance requirement. Unlike other materials that may require regular coatings or treatments to prevent corrosion, stainless steel can often be cleaned with simple soap and water, helping it remain functional and appealing for years. This long-term durability translates to cost savings for businesses and consumers, as replacements become a rare necessity.

Conclusion

In summary, best stainless steel woven wire fabric mesh is a remarkable material that embodies a blend of functionality, durability, and aesthetic appeal. Its properties make it suitable for a myriad of applications across various industries, establishing it as a preferred choice for architectural, manufacturing, and automotive purposes. As industries continue to evolve and innovate, the demand for versatile materials like stainless steel woven wire mesh will undoubtedly grow, affirming its status as a key player in modern engineering solutions. With ongoing advancements in wire mesh technologies and fabrication techniques, the future holds promising potential for even broader applications, solidifying the importance of this material in our everyday lives.

share

-

Premium Twill Weave Mesh for Industrial Filtration & Strength

NewsAug.03,2025

-

CE Certified 250 Micron Stainless Steel Mesh - Durable Filter

NewsAug.02,2025

-

Screen Mesh Price Deals | gpt-4-turbo Optimized Pricing

NewsAug.01,2025

-

CE Certified 250 Micron Stainless Steel Filter Mesh | Premium

NewsJul.31,2025

-

CE Certified 250 Micron Stainless Steel Mesh | Premium Filter

NewsJul.31,2025

-

CE Certification Buy Wire Mesh Fence for High Security and Durability

NewsJul.30,2025