nov . 15, 2024 08:52 Back to list

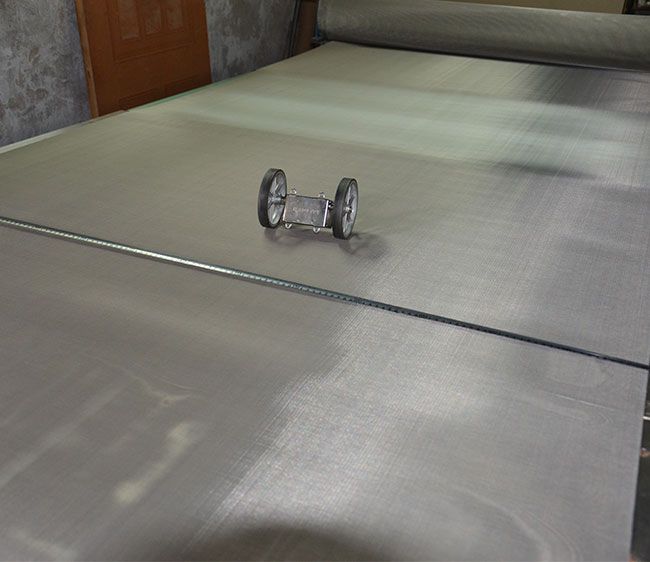

discount fine mesh screens

Understanding Discount Fine Mesh Screens A Practical Guide

In today's market, the necessity for efficient filtration and separation methods has never been more critical. Fine mesh screens are pivotal in various industries, including food processing, pharmaceuticals, and chemicals. These screens enable the separation of solids from liquids, ensuring product purity and safety. As businesses strive for cost-effective solutions, the popularity of discount fine mesh screens has surged, providing an excellent opportunity for companies looking to optimize their processes without breaking the bank.

Fine mesh screens are characterized by their small openings, typically measuring less than 1mm. They come in various materials, with stainless steel being the most common due to its durability and resistance to corrosion. These screens are utilized in several applications, including sifting flour, filtering liquids, and even in the production of cosmetics. The demand for quality filtration has led manufacturers to innovate and offer more efficient screen designs, incorporating features that enhance performance and longevity.

One notable advantage of discount fine mesh screens is their affordability. Purchasing these screens at a discount allows businesses to invest in higher quantities or choose more advanced models that they might otherwise overlook due to budget constraints. Bulk purchasing often leads to significant savings, which can be redirected to enhance other areas of operation, such as upgrading machinery or expanding product lines.

discount fine mesh screens

When searching for discount options, it is essential to consider factors such as the screen's mesh size, material, and design. The mesh size should be compatible with the specific application, ensuring optimal filtration without compromising efficiency. For instance, a screen with a finer mesh may be ideal for filtering out small particles, while a coarser mesh could be suitable for larger debris. Additionally, the material used is crucial; stainless steel screens tend to offer the best balance of strength and corrosion resistance.

Moreover, suppliers often provide customization options for fine mesh screens, allowing businesses to tailor products to their precise needs. This flexibility means that enterprises can optimize their filtration methods, ultimately enhancing product quality and customer satisfaction.

However, while seeking discounts, one must be cautious about the potential trade-offs in quality. It is vital to source screens from reputable suppliers to ensure they meet industry standards. Reading reviews and obtaining samples before a bulk purchase can help mitigate risks associated with lower-priced options. Investing in the right equipment can save costs in the long run by reducing the frequency of replacements and maintaining operational efficiency.

In conclusion, discount fine mesh screens represent a strategic opportunity for businesses aiming to enhance their filtration processes without incurring substantial expenses. Understanding the importance of mesh size, material, and supplier reliability can lead to informed purchasing decisions. By leveraging these tools effectively, companies can improve their operational efficiency while reducing costs, ultimately contributing to better product quality and profitability. Whether you are a small enterprise or a large corporation, fine mesh screens can be a valuable addition to your processing line—especially when sourced at a discount.

share

-

High-Quality Screen Stone for Modern Stone Screen Walls Elegant Facade Solutions

NewsJun.10,2025

-

High Quality Wire Filter – Cheap Stainless Steel Filter Wire Mesh Cloth & Wire Mesh Filter Solutions

NewsJun.10,2025

-

5 Micron Water Filter Cartridge - Premium Sediment Filtration, Universal Fit

NewsJun.10,2025

-

High Quality CE-Certified Gabion Boxes with OEM Options

NewsJun.10,2025

-

20x20x2 Air Filter High-Efficiency Dust Filtration for Clean Air

NewsJun.10,2025

-

Decorative Metal Mesh for Radiator Covers Custom Durable Mesh Panels

NewsJun.10,2025