nov . 29, 2024 09:36 Back to list

Unique Textured Woven Wire Mesh for Enhanced Durability and Aesthetic Appeal

The Versatility and Applications of Famous Woven Crimped Wire Mesh

Woven crimped wire mesh, a staple in the industrial and commercial sectors, has gained notoriety for its exceptional durability and versatility. This type of wire mesh is crafted from high-quality metal wire, which is woven together in a crimped pattern. The crimped structure provides enhanced rigidity and stability, making it ideal for various applications across different fields. In this article, we will explore the properties of woven crimped wire mesh, its manufacturing process, and its myriad applications.

Properties of Woven Crimped Wire Mesh

One of the most striking features of woven crimped wire mesh is its strength. The crimping process alters the structure of the wire, allowing it to withstand higher loads without deformation. This makes it exceptionally suited for heavy-duty applications where other types of mesh might fail. Additionally, the open weave of the mesh allows for excellent air and light penetration while providing adequate filtration.

Another important property is its corrosion resistance. Woven crimped wire mesh can be made from various materials including stainless steel, galvanized steel, and aluminum. Each material offers its own benefits, with stainless steel being particularly favored for its resistance to rust and corrosion in challenging environments. This quality makes the mesh suitable for outdoor applications or in areas where exposure to moisture and chemicals is a concern.

Manufacturing Process

The production of woven crimped wire mesh typically begins with high-quality wire rods. These rods undergo a process of drawing and crimping to attain the required dimensions and strength. The crimping can be achieved through various methods where the wire is passed through a crimping machine, ensuring consistency in the crimp patterns.

After crimping, the wires are woven together using a loom, which ensures that the specific mesh size and diameter are achieved. Different weaving techniques, such as plain weave or twill weave, can be applied depending on the intended use of the mesh. Once woven, the finished product can be treated with protective coatings to enhance its durability, particularly in corrosive environments.

Applications of Woven Crimped Wire Mesh

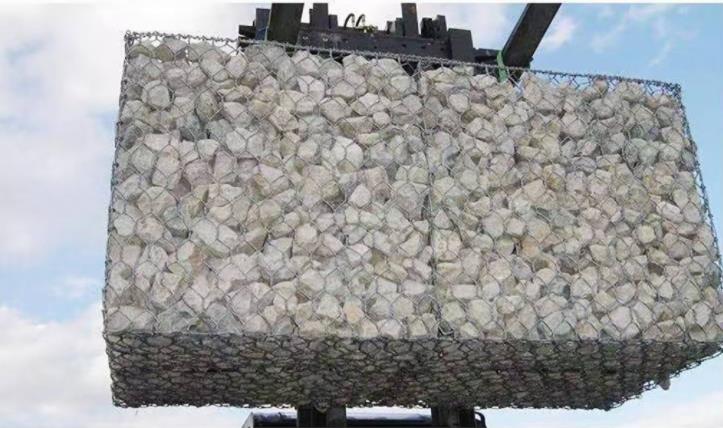

famous woven crimped wire mesh

Woven crimped wire mesh has a wide range of applications across various industries. Its most common uses include

1. Filtration In industrial settings, woven crimped wire mesh is often employed as a filter medium due to its structural integrity and open weave. It is commonly used in water treatment plants, oil and gas filtration, and air purification systems.

2. Construction In the construction industry, this type of mesh serves as reinforcement for concrete and is often used in fencing, as a support structure for plastering, or as protective barriers.

3. Mining and Quarrying Due to its strength and durability, woven crimped wire mesh is frequently utilized in the mining industry for screening and sorting materials. It is capable of withstanding harsh conditions and heavy loads.

4. Automotive and Aerospace The automotive and aerospace sectors utilize crimped wire mesh for components such as intake screens, heat exchangers, and even as noise reduction barriers.

5. Agriculture In agriculture, woven crimped wire mesh is used in a variety of applications from animal enclosures to seedbed screens, providing essential support and protection.

6. Interior and Exterior Design With its aesthetic appeal, woven crimped wire mesh is increasingly found in architectural applications, such as decorative facades, room dividers, and railings, where it combines functionality with modern design elegance.

Conclusion

The fame of woven crimped wire mesh is rooted in its remarkable properties, robust performance, and the diverse range of applications it serves. Whether in heavy industry or artistic design, this versatile mesh continues to be a valuable resource, providing solutions that meet the needs of various sectors. As technology advances and new materials are developed, the potential for woven crimped wire mesh remains vast and exciting, ensuring its role as a fundamental material in many industries.

share

-

CE Certified 250 Micron Stainless Steel Filter Mesh | Premium

NewsJul.31,2025

-

CE Certified 250 Micron Stainless Steel Mesh | Premium Filter

NewsJul.31,2025

-

CE Certification Buy Wire Mesh Fence for High Security and Durability

NewsJul.30,2025

-

Stainless Steel Mesh Filter Discs for Precise Filtration Solutions

NewsJul.29,2025

-

CE Certification 250 Micron Stainless Steel Mesh for Industrial Use

NewsJul.29,2025

-

Premium Stainless Steel Weave Mesh for Filtration and Security

NewsJul.29,2025