sep . 30, 2024 23:02 Back to list

High-Quality 20 Micron Stainless Steel Mesh for Enhanced Filtration and Durability

The Importance of High-Quality 20 Micron Stainless Steel Mesh

In various industrial applications, the choice of materials is crucial as it directly affects the performance, sustainability, and overall success of operations. Among these materials, stainless steel mesh stands out due to its remarkable properties and versatility. Specifically, high-quality 20 micron stainless steel mesh has gained significant attention. This article will explore its characteristics, applications, and the benefits it offers across different sectors.

What is Stainless Steel Mesh?

Stainless steel mesh is a woven or welded screen made from stainless steel wires. Known for its superior strength, corrosion resistance, and durability, stainless steel mesh is widely used in filtration, sieving, and as a barrier in various applications. The 20 micron specification refers to the size of the openings in the mesh, which measures 20 microns or 0.02 millimeters. This level of fineness allows the mesh to filter out very small particles, making it suitable for applications that require precise filtration.

The Significance of 20 Micron Mesh

The 20 micron size is critical for applications where ultra-fine filtration is necessary. In industries such as pharmaceuticals, food processing, and chemicals, maintaining high purity levels is essential for product quality and safety. The high-quality 20 micron stainless steel mesh effectively traps contaminants, ensuring that end products meet regulatory compliance and quality standards.

Applications of High-Quality 20 Micron Stainless Steel Mesh

1. Filtration Systems In wastewater treatment plants, high-quality stainless steel mesh is used for filtering out debris and contaminants. Its fine mesh size ensures that even tiny particles do not pass through, contributing to cleaner effluent and minimizing environmental impact.

2. Pharmaceutical Industry In the production of medicines, maintaining a sterile environment is paramount. The 20 micron stainless steel mesh is utilized to filter out small particulates during the manufacturing process, helping to ensure that the final products are safe for consumption.

3. Food Processing In food manufacturing, stainless steel mesh plays a vital role in ensuring food safety and quality. The mesh is used in various processes, from separating different food ingredients to filtering liquids. Its corrosion resistance ensures that it can withstand harsh cleaning chemicals without degrading.

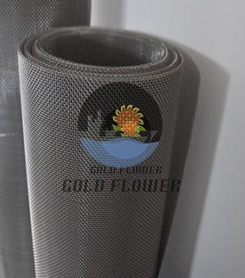

high quality 20 micron stainless steel mesh

4. Chemical Processing For chemical engineers, having reliable filtration systems is crucial. The 20 micron mesh can efficiently capture undissolved solids in various chemical reactions, aiding in the production of high-purity chemicals.

5. Industrial Applications Beyond food and pharmaceuticals, high-quality stainless steel mesh is employed in a variety of industrial applications, such as mining and oil and gas extraction, where it is used for separating minerals and other particulates from liquids.

Advantages of Using High-Quality 20 Micron Stainless Steel Mesh

1. Durability Stainless steel is known for its exceptional strength and resistance to corrosion, which extends the life of the mesh and minimizes replacement costs.

2. Efficiency The fine filtration capabilities of 20 micron mesh ensure that operational processes run smoothly with fewer interruptions due to blockages or contamination.

3. Versatility This type of mesh can be tailored for various applications, making it an adaptable solution for different industries.

4. Eco-Friendly The use of stainless steel mesh is environmentally friendly as it can be recycled, reducing waste and promoting sustainable practices.

Conclusion

High-quality 20 micron stainless steel mesh is an essential component in many industrial systems where cleanliness and precision are paramount. Its combination of durability, efficiency, and versatility makes it an invaluable asset across a wide range of applications. As industries continue to prioritize quality and sustainability, the demand for this exceptional material is expected to grow, reaffirming its role as a cornerstone in modern manufacturing and processing environments.

share

-

CE Certified 250 Micron Stainless Steel Mesh for Precision Filtration

NewsAug.22,2025

-

CE Certified 250 Micron SS Mesh - Precision Filtration & Strength

NewsAug.21,2025

-

CE Certified Woven Wire Mesh Filters | Premium Filtration Solutions

NewsAug.19,2025

-

High-Performance Particle Filters: Optimal Mediums & Applications

NewsAug.18,2025

-

Competitive Screen Mesh Price | 1/4", 1/8", 1/2" Wire Mesh Screens

NewsAug.17,2025

-

CE Certified 250 Micron SS Mesh: Precision & Durability

NewsAug.15,2025