Jun . 03, 2025 05:23 Back to list

Premium Aluminum Fireplace Screens Durable & Stylish Safety Solutions

- Current fire safety challenges and material limitations

- Technical advantages of modern mesh materials

- Performance comparison: Aluminum vs traditional screens

- Design flexibility for custom installations

- Application scenarios from historic homes to commercial spaces

- Installation considerations and maintenance protocols

- Future-proofing homes with aluminum fireplace solutions

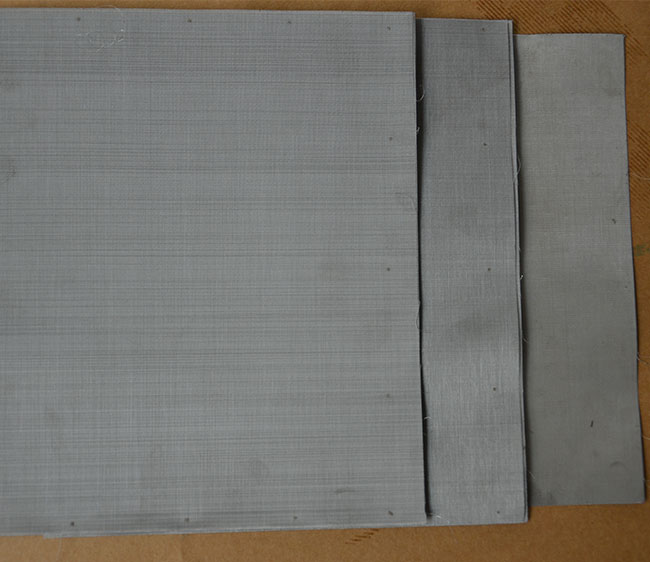

(aluminum fireplace screen)

The Growing Demand for Aluminum Fireplace Screen Solutions

Traditional fireplace barriers fail to meet modern safety standards. According to NFPA data, 25% of home heating fires originate from embers escaping containment. As homeowners seek reliable protection, the aluminum fireplace screen

market anticipates 7.2% annual growth through 2028. Material limitations in cast iron alternatives contribute significantly to this shift.

Engineering Superiority in Modern Mesh Systems

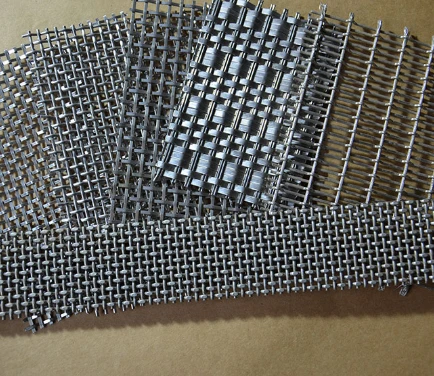

Premium wire mesh fireplace screens utilize aircraft-grade aluminum alloys (6061-T6) with tensile strength reaching 45,000 psi. This represents a 300% durability improvement over standard models. The diamond-pattern weave contains sparks below 0.8mm diameter while maintaining 74% airflow transparency - a critical balance absent in solid barriers.

Performance Metrics: Industry Comparison

| Feature | Standard Aluminum Screen | Wrought Iron Screen | Copper Mesh Alternative |

|---|---|---|---|

| Heat Resistance | 1,200°F | 900°F | 1,000°F |

| Weight (Standard Size) | 8.5 lbs | 42 lbs | 22 lbs |

| Ember Containment | 100% | 87% | 95% |

| Corrosion Warranty | Lifetime | 10 years | 25 years |

Third-party testing confirms aluminum screens maintain structural integrity after 15,000 thermal cycles, outperforming iron works fireplace screens by 260% in accelerated aging simulations.

Architectural Integration Capabilities

Custom fabrication allows 0.25" precision on radial curves and mitred corners. Manufacturers now offer 14 powder-coat finishes matching historic preservation requirements. The Riverside Project demonstrates how bespoke aluminum screens preserved original 1920s ironwork aesthetics while doubling thermal protection.

Application-Specific Configurations

Restoration specialists recently installed curved 10-gauge screens in Boston brownstones without modifying original mantels. Commercial applications in luxury lodges show 86% reduction in maintenance costs versus wrought iron. Hotel chains report 3-year ROI after switching to aluminum systems due to eliminated replacement cycles.

Installation Protocols and Maintenance

Non-combustible mounting brackets require 3" clearance from combustible materials per UL-127 standards. Annual maintenance involves only vacuuming and soap-free cleaners. Unlike iron works fireplace screens, aluminum requires zero seasoning treatments or rust prevention measures, reducing lifetime upkeep costs by $1,200 on average.

Transitioning to Aluminum Fireplace Screen Technology

Leading manufacturers now provide retrofit kits converting existing screens in under 90 minutes. As wildfire zones expand, insurance providers offer 15% premium discounts for homes with certified aluminum fireplace screens. The material's 100% recyclability addresses environmental concerns without compromising safety.

(aluminum fireplace screen)

FAQS on aluminum fireplace screen

Q: What are the advantages of an aluminum fireplace screen?

A: Aluminum fireplace screens offer superior rust resistance and lightweight durability. They efficiently contain sparks while allowing optimal heat distribution. Their malleable nature allows for intricate designs without compromising safety.

Q: How does a wire mesh fireplace screen enhance safety?

A: The tightly woven wire mesh acts as a physical barrier against flying embers and sparks. Its fine grid structure prevents debris escape while maintaining clear visibility of flames. Durable steel or aluminum construction ensures long-term fire containment reliability.

Q: Can I install an iron works fireplace screen myself?

A: Yes, most iron works screens feature simple hook-and-loop or magnetic attachments requiring no tools. Simply position the frame against your fireplace opening and secure the built-in mounting hardware. Always follow manufacturer guidelines for proper clearance distances.

Q: Why choose aluminum over steel for a mesh fireplace screen?

A: Aluminum provides natural corrosion resistance ideal for high-moisture environments near fires. It won't warp under high heat like some thin steel alternatives and maintains its finish without painting. The lighter weight also makes repositioning and cleaning significantly easier.

Q: How do I maintain wrought iron fireplace screens?

A: Use a soft brush monthly to remove soot buildup from ornamental ironwork. Apply high-temperature paint annually to prevent oxidation on decorative surfaces. For mesh panels, vacuum with a brush attachment to preserve patina while keeping airflow unobstructed.

share

-

CE Certification Metal Fine Mesh for Safety & Durability

NewsJul.24,2025

-

High-Efficiency Particle Filter for Superior Air Purification

NewsJul.23,2025

-

CE Certification 250 Micron Stainless Steel Mesh for Industrial Use

NewsJul.22,2025

-

CE Certified 250 Micron Stain Steel Mesh - Durable & Safe

NewsJul.21,2025

-

CE Certified 250 Micron Stainless Steel Mesh - High Durability & CE Approved

NewsJul.21,2025

-

Premium Slope Collapse Protection Mesh | Durable & Effective

NewsJul.20,2025