Mar . 04, 2025 02:02 Back to list

buy 5mm stainless steel mesh

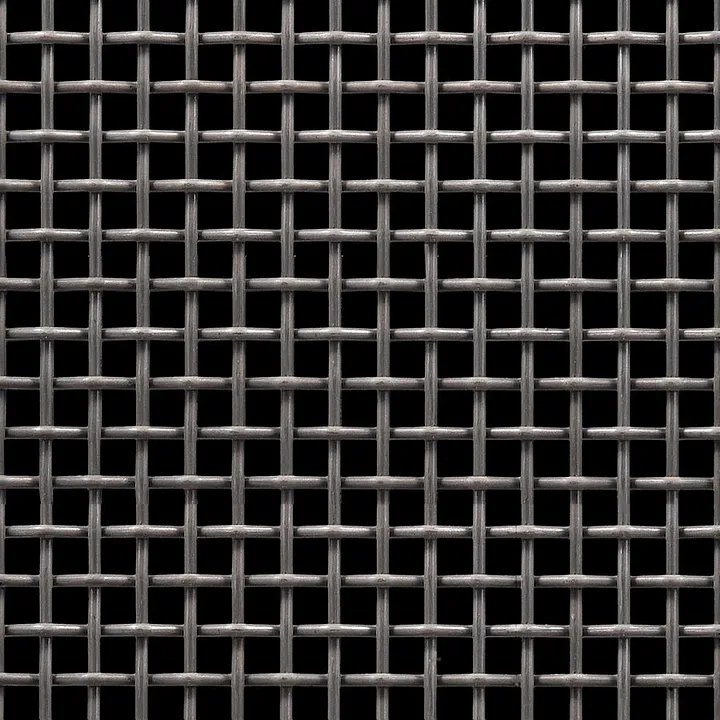

In the vast arena of construction and industrial materials, stainless steel mesh stands out for its durability, versatility, and reliability. Specifically, the 5mm stainless steel mesh gains a spotlight for its robustness and precision. When considering the purchase of this material, understanding its applications, benefits, and selection criteria becomes imperative.

When deciding to purchase 5mm stainless steel mesh, several factors must be considered to ensure product quality and suitability for the intended application. First and foremost, evaluating the mesh's grade of stainless steel is critical. The most common grades used are 304 and 316, with the latter offering superior corrosion resistance, making it ideal for marine environments or projects exposed to corrosive elements. Furthermore, assessing the weave of the mesh is pivotal. The weave impacts not only the strength but also the functionality of the mesh. Different weave patterns, such as plain weave or twilled weave, offer varied benefits, from enhanced strength to improved filtration accuracy. Understanding these nuances helps in selecting the right type for the specific needs of your project. Supplier credibility is another crucial aspect when purchasing 5mm stainless steel mesh. Reliable suppliers will provide detailed product specifications, certifications, and quality assurance guarantees, fostering trust and ensuring you receive a product that meets your expectations. Engaging with suppliers who have a proven track record and positive reviews can avert potential discrepancies in product quality and delivery. Lastly, the cost considerations of 5mm stainless steel mesh cannot be overlooked. While opting for cheaper alternatives might be tempting, it’s important to consider the long-term implications of such choices. Investing in higher-quality stainless steel mesh may entail higher upfront costs, but its longevity, reduced maintenance requirements, and superior performance offer better value in the long run. In essence, the decision to buy 5mm stainless steel mesh is not merely a matter of selecting a functional material. It encompasses a broader spectrum of considerations, which include understanding the specific needs of your project, evaluating the material’s attributes and sustainability, and selecting a credible supplier. These factors collectively ensure a purchase decision that stands the test of time and delivers tangible benefits across diverse applications. By approaching the purchase strategically, you ensure that this vital material enhances the value, efficiency, and sustainability of your projects, reflecting a commitment to quality and innovation.

When deciding to purchase 5mm stainless steel mesh, several factors must be considered to ensure product quality and suitability for the intended application. First and foremost, evaluating the mesh's grade of stainless steel is critical. The most common grades used are 304 and 316, with the latter offering superior corrosion resistance, making it ideal for marine environments or projects exposed to corrosive elements. Furthermore, assessing the weave of the mesh is pivotal. The weave impacts not only the strength but also the functionality of the mesh. Different weave patterns, such as plain weave or twilled weave, offer varied benefits, from enhanced strength to improved filtration accuracy. Understanding these nuances helps in selecting the right type for the specific needs of your project. Supplier credibility is another crucial aspect when purchasing 5mm stainless steel mesh. Reliable suppliers will provide detailed product specifications, certifications, and quality assurance guarantees, fostering trust and ensuring you receive a product that meets your expectations. Engaging with suppliers who have a proven track record and positive reviews can avert potential discrepancies in product quality and delivery. Lastly, the cost considerations of 5mm stainless steel mesh cannot be overlooked. While opting for cheaper alternatives might be tempting, it’s important to consider the long-term implications of such choices. Investing in higher-quality stainless steel mesh may entail higher upfront costs, but its longevity, reduced maintenance requirements, and superior performance offer better value in the long run. In essence, the decision to buy 5mm stainless steel mesh is not merely a matter of selecting a functional material. It encompasses a broader spectrum of considerations, which include understanding the specific needs of your project, evaluating the material’s attributes and sustainability, and selecting a credible supplier. These factors collectively ensure a purchase decision that stands the test of time and delivers tangible benefits across diverse applications. By approaching the purchase strategically, you ensure that this vital material enhances the value, efficiency, and sustainability of your projects, reflecting a commitment to quality and innovation.

share

Next:

Latest news

-

CE Certified 250 Micron Stainless Steel Filter Mesh | Premium

NewsJul.31,2025

-

CE Certified 250 Micron Stainless Steel Mesh | Premium Filter

NewsJul.31,2025

-

CE Certification Buy Wire Mesh Fence for High Security and Durability

NewsJul.30,2025

-

Stainless Steel Mesh Filter Discs for Precise Filtration Solutions

NewsJul.29,2025

-

CE Certification 250 Micron Stainless Steel Mesh for Industrial Use

NewsJul.29,2025

-

Premium Stainless Steel Weave Mesh for Filtration and Security

NewsJul.29,2025