Feb . 14, 2025 04:26 Back to list

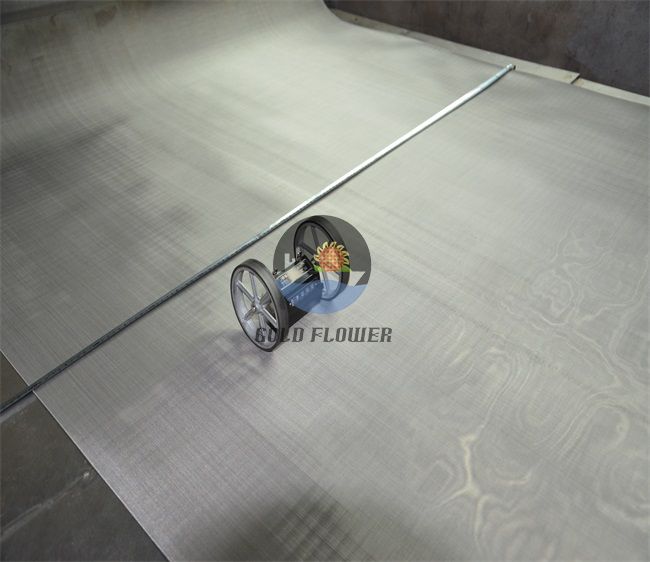

400 stainless steel mesh

Stainless steel mesh is an essential component in various industries, offering a blend of strength, durability, and versatility. When considering purchasing this vital material, understanding its applications, benefits, and selection criteria can immensely enhance the buying experience, ensuring optimal utilization across different projects. This guide aims to provide a comprehensive overview for those keen on integrating stainless steel mesh into their ventures, underpinning decisions with an expert perspective.

Product experts understand that the weave type—whether plain, twill, or Dutch—can influence the mesh's performance. Plain weaves suit general-purpose applications, providing balanced strength and durability. For tasks requiring higher filtration precision, twill Dutch and reverse Dutch weaves are advised due to their enhanced particle retention capabilities. Establishing trustworthiness in choosing a supplier involves verifying the quality control processes employed by manufacturers. Reputable suppliers will have ISO certification and adhere to ASTM standards, ensuring that the stainless steel mesh meets international quality and safety requirements. Verified customer reviews and industry recommendations will also guide purchasing decisions, showcasing a supplier's reliability and expertise in the field. When evaluating the cost of stainless steel mesh, consider both upfront expenses and long-term value. Superior quality mesh may have a higher initial cost, but its durability and reduced maintenance requirements render it a more economical choice over time. Additionally, leveraging modern technology to incorporate custom designs and sizes can further improve efficiency and application-specific suitability, providing tailored solutions that align with project goals. In conclusion, buying stainless steel mesh is an investment in durability, versatility, and efficiency. With informed choices backed by expert guidance, individuals and businesses can ensure optimal performance and value from their stainless steel mesh applications. This not only facilitates robust industrial processes but also supports sustainable practices—highlighting the imperative of quality and longevity in material selection.

Product experts understand that the weave type—whether plain, twill, or Dutch—can influence the mesh's performance. Plain weaves suit general-purpose applications, providing balanced strength and durability. For tasks requiring higher filtration precision, twill Dutch and reverse Dutch weaves are advised due to their enhanced particle retention capabilities. Establishing trustworthiness in choosing a supplier involves verifying the quality control processes employed by manufacturers. Reputable suppliers will have ISO certification and adhere to ASTM standards, ensuring that the stainless steel mesh meets international quality and safety requirements. Verified customer reviews and industry recommendations will also guide purchasing decisions, showcasing a supplier's reliability and expertise in the field. When evaluating the cost of stainless steel mesh, consider both upfront expenses and long-term value. Superior quality mesh may have a higher initial cost, but its durability and reduced maintenance requirements render it a more economical choice over time. Additionally, leveraging modern technology to incorporate custom designs and sizes can further improve efficiency and application-specific suitability, providing tailored solutions that align with project goals. In conclusion, buying stainless steel mesh is an investment in durability, versatility, and efficiency. With informed choices backed by expert guidance, individuals and businesses can ensure optimal performance and value from their stainless steel mesh applications. This not only facilitates robust industrial processes but also supports sustainable practices—highlighting the imperative of quality and longevity in material selection.

share

Latest news

-

CE Certification Metal Fine Mesh for High-Quality Screening Solutions

NewsJul.26,2025

-

CE Certification 250 Micron Stainless Steel Mesh for Industrial Use

NewsJul.25,2025

-

CE Certification Metal Fine Mesh for Safety & Durability

NewsJul.24,2025

-

High-Efficiency Particle Filter for Superior Air Purification

NewsJul.23,2025

-

CE Certification 250 Micron Stainless Steel Mesh for Industrial Use

NewsJul.22,2025

-

CE Certified 250 Micron Stain Steel Mesh - Durable & Safe

NewsJul.21,2025