Nov . 07, 2024 09:45 Back to list

ce certification 120 micron steel screen

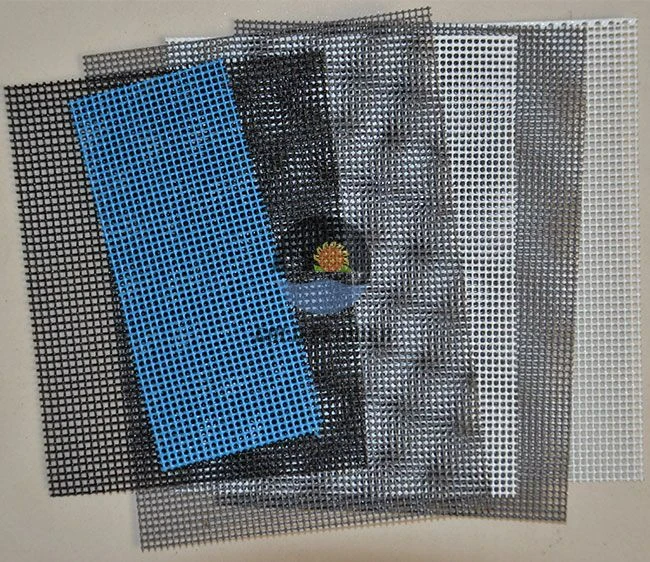

Understanding CE Certification for 120 Micron Steel Screens

In industries where filtration and separation are paramount, the specifications of materials play a crucial role in defining efficiency and performance. One such specification that often comes into focus is the CE certification of steel screens, particularly those with a mesh size of 120 microns. This article aims to elucidate the significance of CE certification, the unique properties of 120 micron steel screens, and their applications across different sectors.

CE certification, or Conformité Européenne mark, is a mandatory conformity mark for products sold within the European Economic Area (EEA). It indicates that a product meets the essential health, safety, and environmental requirements set out by European legislation. For manufacturers of 120 micron steel screens, obtaining CE certification is a critical milestone. It not only assures compliance with European standards but also builds trust with customers by highlighting the product's reliability and safety.

When we specifically talk about 120 micron steel screens, we refer to screens that have openings of 120 microns, which is equivalent to 0.12 millimeters. This fineness allows these screens to filter out very small particles, making them suitable for various applications, including chemical processing, food and beverage production, and wastewater treatment. The ability to effectively separate solids from liquids ensures that the end products meet quality standards and are free from contaminants.

ce certification 120 micron steel screen

The manufacturing process of 120 micron steel screens often involves using high-quality stainless steel, which provides excellent resistance to corrosion and wear. This durability is essential, as filtration applications can subject screens to intense conditions, including exposure to harsh chemicals and high temperatures. Additionally, the precise construction of these screens ensures that they maintain their shape and functionality over time, even under rigorous operating conditions.

One of the primary applications for CE-certified 120 micron steel screens is in the food industry, where hygiene and safety are of utmost importance. These screens can be used in processes such as brewing, where they help separate grains from liquids, and in juice production, where they remove pulp to achieve a smooth texture. The CE certification assures manufacturers that their products conform to stringent EU regulations, making the screening process more efficient and compliant.

In the industrial sector, these steel screens are utilized in various filtration processes. For instance, in chemical manufacturing, they can be employed to separate solids from slurries, ensuring the purity of the final product. In wastewater treatment, 120 micron screens play a crucial role in removing particulate matter from effluents, thus enhancing the quality of water being discharged into the environment.

In conclusion, the CE certification of 120 micron steel screens is vital for ensuring quality, safety, and compliance in numerous applications. As industries continue to push for higher standards and more efficient processes, the role of certified filtration solutions becomes increasingly important. Investing in reliable, CE-certified materials not only adheres to regulatory standards but also contributes to the overall integrity of production processes across various sectors.

share

-

5mm Stainless Steel Mesh Best Quality & Custom OEM Solutions

NewsMay.19,2025

-

20x25x4 Furnace Filter MERV 11 Dust & Allergen Defense, 60+ Day Protection

NewsMay.19,2025

-

Ornamental Expanded Metal Sheets Durable & Custom Garden Designs

NewsMay.19,2025

-

Black Chain Link Fence Costs Affordable Pricing & Installation Estimates

NewsMay.18,2025

-

Stainless Steel Chicken Mesh Durable & Corrosion-Resistant Fencing

NewsMay.18,2025

-

Affordable Cabin Air Filter Cost & Replacement Tips Save Now!

NewsMay.17,2025