Nov . 26, 2024 08:01 Back to list

High-Performance Stainless Steel Mesh Screens for Various Applications

The Versatility and Importance of Famous SS Mesh Screens

In various industries, the demand for efficient filtration systems is ever-increasing. Stainless steel (SS) mesh screens have risen to prominence due to their unique properties and wide-ranging applications. Known for their durability, corrosion resistance, and excellent filtration capabilities, these screens have become essential tools across multiple sectors, such as food processing, pharmaceuticals, and chemical manufacturing.

Stainless steel mesh screens are made from high-quality SS wire woven into various mesh sizes, which dictates the screen's porosity and filtration efficiency. The versatility of these screens allows them to be tailored for specific applications, whether it be for coarse filtration or fine mesh separation. For instance, in the food industry, SS mesh screens are utilized to filter liquids and separate solids efficiently, ensuring that the final product is pure and free from contaminants.

The Versatility and Importance of Famous SS Mesh Screens

The cleaning process for stainless steel mesh screens is also relatively straightforward, which adds to their appeal. Often, these screens can be cleaned and reused multiple times without losing their filtration efficiency. This feature not only minimizes waste but also supports performance stability, making them a preferred choice for manufacturers striving for sustainability.

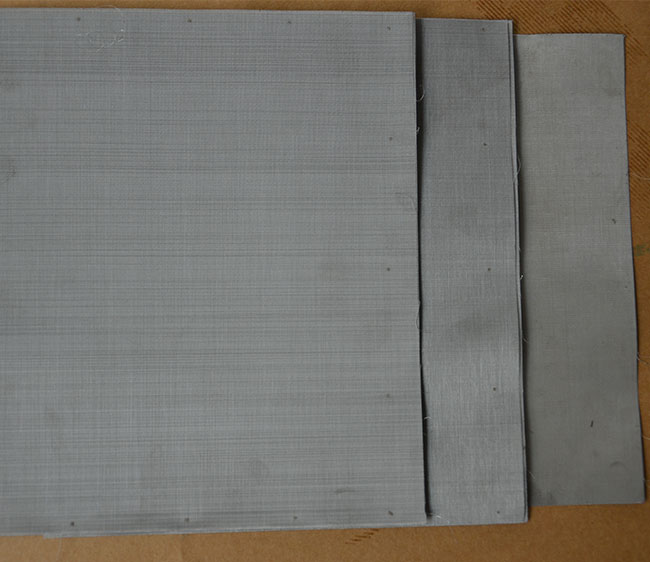

famous ss mesh screen

Moreover, the use of stainless steel mesh screens extends to safety applications. In the pharmaceutical industry, they play a crucial role in ensuring that medications are produced without contamination. The stringent regulations surrounding pharmaceutical manufacturing necessitate the highest levels of cleanliness, and SS mesh screens help maintain that standard.

Additionally, in construction and civil engineering, SS mesh screens are employed for safety applications, such as preventing debris from falling and ensuring worker safety. This multifaceted utility demonstrates the screens' capability to meet diverse safety and operational requirements across various fields.

The customization of stainless steel mesh screens further enhances their appeal. Manufacturers can offer a range of woven patterns, wire diameters, and mesh openings to meet specific filtration needs. This tailored approach allows engineers and designers to choose the right specifications based on their unique operational demands, thereby enhancing efficiency and productivity.

In conclusion, stainless steel mesh screens are far more than just filtration tools. Their strength, longevity, and adaptability make them indispensable in many industries. As technology advances and the need for more refined filtration processes grows, the popularity of stainless steel mesh screens is likely to continue to rise. Businesses that invest in these high-quality filtration solutions can expect improved operational effectiveness and enhanced product safety in their production processes. With numerous benefits, stainless steel mesh screens will remain a vital component in ensuring the quality and safety of various products across multiple sectors.

share

-

High-Quality Screen Stone for Modern Stone Screen Walls Elegant Facade Solutions

NewsJun.10,2025

-

High Quality Wire Filter – Cheap Stainless Steel Filter Wire Mesh Cloth & Wire Mesh Filter Solutions

NewsJun.10,2025

-

5 Micron Water Filter Cartridge - Premium Sediment Filtration, Universal Fit

NewsJun.10,2025

-

High Quality CE-Certified Gabion Boxes with OEM Options

NewsJun.10,2025

-

20x20x2 Air Filter High-Efficiency Dust Filtration for Clean Air

NewsJun.10,2025

-

Decorative Metal Mesh for Radiator Covers Custom Durable Mesh Panels

NewsJun.10,2025