Nov . 28, 2024 06:50 Back to list

Versatile Aluminum Wire Mesh Solutions for Various Applications and Industries

The Versatility of ODM Wire Mesh Aluminum A Comprehensive Overview

Aluminum wire mesh, specifically through Original Design Manufacturer (ODM) processes, has emerged as a paramount material in various industries. Its unique blend of properties not only enhances functionality but also offers aesthetic value, making it a sought-after choice in manufacturing and construction applications. This article will delve into the benefits, applications, and manufacturing processes of ODM wire mesh aluminum.

Understanding ODM Wire Mesh Aluminum

ODM refers to the practice where manufacturers create products based on specifications provided by another company. When it comes to aluminum wire mesh, this means crafting customized mesh solutions tailored to specific client needs. Aluminum itself is a lightweight, durable, and corrosion-resistant metal, which, when woven into a mesh form, offers an array of benefits that are hard to match by other materials like steel or plastic.

Benefits of Aluminum Wire Mesh

1. Lightweight Nature One of the foremost advantages of aluminum wire mesh is its lightweight property. This characteristic not only aids in ease of handling and installation but also minimizes structural loads, making it ideal for applications where weight is a concern.

2. Corrosion Resistance Aluminum has an inherent resistance to corrosion due to the formation of a protective oxide layer when oxidized. This property makes aluminum wire mesh particularly suitable for outdoor and industrial applications where exposure to moisture and harsh conditions is common.

3. Aesthetic Appeal ODM aluminum wire mesh can be finished in various ways, including anodizing and powder coating. These finishes enhance its appearance, making it an attractive option for architectural applications, interior design, and even decorative purposes.

4. Versatile Applications The adaptability of aluminum wire mesh allows it to be used in various sectors, ranging from construction and automotive to food processing and filtration systems. It can serve functions including safety barriers, screens, filters, and separation grids.

Applications of ODM Wire Mesh Aluminum

1. Construction Industry In construction, aluminum wire mesh is often used for safety barriers and protective screens. Its strength and lightweight nature make it ideal for scaffolding applications, ensuring worker safety while also being easy to install and dismantle.

odm wire mesh aluminum

2. Architecture and Design In architectural projects, architects utilize aluminum mesh for facades, sunshades, and decorative elements due to its striking visual appeal. It allows for creative design while maintaining functionality, providing ventilation without compromising on aesthetic value.

3. Filtration Systems The industrial sector employs aluminum wire mesh for various filtration applications. It is used in water treatment plants, air filtration systems, and food processing facilities due to its ability to trap contaminants while allowing for proper fluid flow.

4. Transportation In the automotive and aerospace industries, aluminum wire mesh is used for lightweight structural components as well as screens and grills. Its strength-to-weight ratio is crucial for enhancing efficiency and performance.

Manufacturing Process

The manufacturing of ODM wire mesh aluminum typically involves several key steps

1. Material Selection High-grade aluminum is sourced based on the requirements specified by the client, ensuring optimal performance.

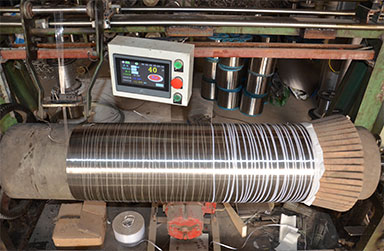

2. Wire Drawing Aluminum rods are drawn into wire of desired gauges, preparing them for weaving.

3. Weaving The drawn wires are then interlaced through various weaving techniques to create mesh sheets. ODM manufacturers can customize the weave pattern, mesh size, and thickness according to client specifications.

4. Finishing Finally, the mesh undergoes finishing processes like anodizing, powder coating, or painting to enhance durability and aesthetics.

Conclusion

In summary, ODM wire mesh aluminum exemplifies a blend of practicality and design, making it a pivotal material across numerous industries. With its lightweight, corrosion-resistant, and customizable features, aluminum wire mesh caters to a wide range of applications, proving indispensable in modern manufacturing and construction. As industries continue to evolve, the demand for such innovative materials will undoubtedly grow, paving the way for further advancements in design and functionality. The value of ODM wire mesh aluminum is clear, and its potential continues to expand, promising a bright future in a multitude of applications.

share

-

CE Certified 250 Micron Stainless Steel Mesh | Precision & Durability

NewsAug.27,2025

-

CE Certified 250 Micron Stainless Steel Mesh for Precision & Durability

NewsAug.26,2025

-

CE Certified 250 Micron Stainless Steel Mesh for Precision & Durability

NewsAug.25,2025

-

Premium CE Certified Metal Fine Mesh for Precision & Safety

NewsAug.24,2025

-

Stainless Steel Wedge Wire Mesh: Durable, Precision Filtration

NewsAug.23,2025

-

CE Certified 250 Micron Stainless Steel Mesh for Precision Filtration

NewsAug.22,2025