Nov . 06, 2024 07:45 Back to list

Custom Steel Crimped Mesh Solutions for Industrial Applications and Construction Needs

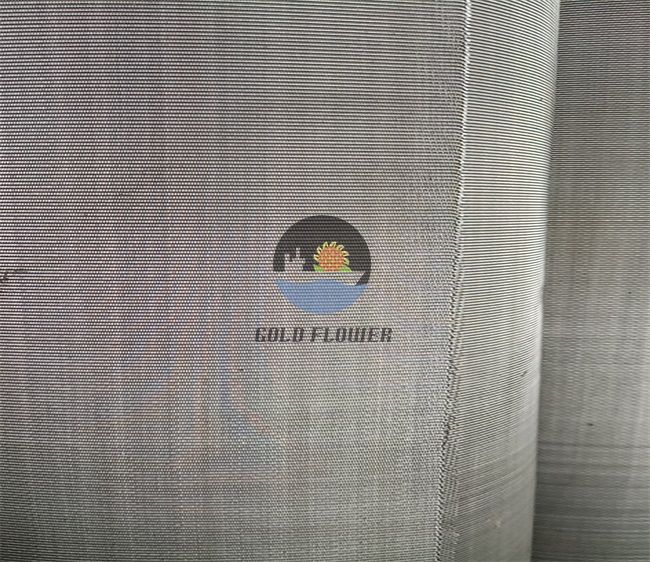

The Versatility and Applications of OEM Steel Crimped Mesh

In the world of industrial manufacturing and construction, the phrase OEM steel crimped mesh frequently arises. Understanding both its definition and its applications is vital for anyone working with or around metal products. This article will explore what OEM steel crimped mesh is, its manufacturing process, properties, and its various uses in different sectors.

What is OEM Steel Crimped Mesh?

OEM stands for Original Equipment Manufacturer, a term that signifies products made to be used as components in other goods. When we talk about steel crimped mesh, we're referring to a type of wire mesh that is made from steel wires that have been crimped—meaning they’ve been pressed to create a wave-like pattern. This crimping enhances their strength and stability, making them an ideal choice for various applications.

The manufacturing process involves weaving the crimped wires together, resulting in a robust mesh that has unique characteristics such as increased load-bearing capacity and minimized deformation under stress. The production can be tailored to meet specific requirements, which is the hallmark of OEM manufacturing. Thus, customers receive custom-made solutions that meet their operational demands.

Properties of OEM Steel Crimped Mesh

1. Durability Steel crimped mesh is inherently sturdy. It is resistant to various environmental factors including moisture, which makes it ideal for outdoor applications where exposure to the elements is a concern.

2. Versatility This type of mesh comes in various sizes and designs. It can be produced in different wire gauges, and the spacing between the crimped wires can be adjusted according to specific needs.

4. Cost-effectiveness While steel is typically more expensive than other materials, its longevity and the reduced need for frequent replacements make steel crimped mesh an economically sound choice over time.

oem steel crimped mesh

5. Ease of Installation The uniformity in design allows for quick and efficient installation, saving time and labor costs.

Applications of OEM Steel Crimped Mesh

OEM steel crimped mesh is utilized across multiple industries due to its impressive array of properties. Here are some primary applications

1. Construction In the construction industry, steel crimped mesh is widely used for reinforcement in concrete slabs, walls, and other structures. It helps improve tensile strength and minimizes the risk of cracks.

2. Mining The mining sector employs crimped mesh for separating materials. It is especially useful for creating screens that can filter out debris while allowing valuable minerals to pass through.

3. Agriculture Crimped mesh is also used in agriculture for creating enclosures or cages for livestock. Its sturdy construction ensures the safety of animals while still allowing adequate airflow.

4. Transport and Storage In warehouses, crimped mesh can serve as a reliable storage solution for items of various sizes. It can be woven into racks or used to create barriers and supports for stacked goods.

5. Architecture and Design Recently, designers have begun to embrace steel crimped mesh in architectural applications, incorporating it into staircases, partitions, and as decorative features. Its aesthetic appeal combined with structural functionality makes it a promising choice.

Conclusion

In conclusion, OEM steel crimped mesh is more than just a material; it's an essential component across various industries. With its durability, versatility, and range of properties, it provides innovative solutions to complex challenges. Whether in construction, agriculture, or even artistic installations, the demand for this type of mesh continues to grow as industries recognize its numerous advantages. By opting for OEM steel crimped mesh, businesses not only invest in a reliable product but also in the future of their operations.

share

-

Premium Stainless Steel Netting Mesh Discount & ODM Stainless Steel Wire Mesh Solutions

NewsJun.24,2025

-

High-Quality Screen Stone for Modern Stone Screen Walls Elegant Facade Solutions

NewsJun.10,2025

-

High Quality Wire Filter – Cheap Stainless Steel Filter Wire Mesh Cloth & Wire Mesh Filter Solutions

NewsJun.10,2025

-

5 Micron Water Filter Cartridge - Premium Sediment Filtration, Universal Fit

NewsJun.10,2025

-

High Quality CE-Certified Gabion Boxes with OEM Options

NewsJun.10,2025

-

20x20x2 Air Filter High-Efficiency Dust Filtration for Clean Air

NewsJun.10,2025