Oct . 10, 2024 07:05 Back to list

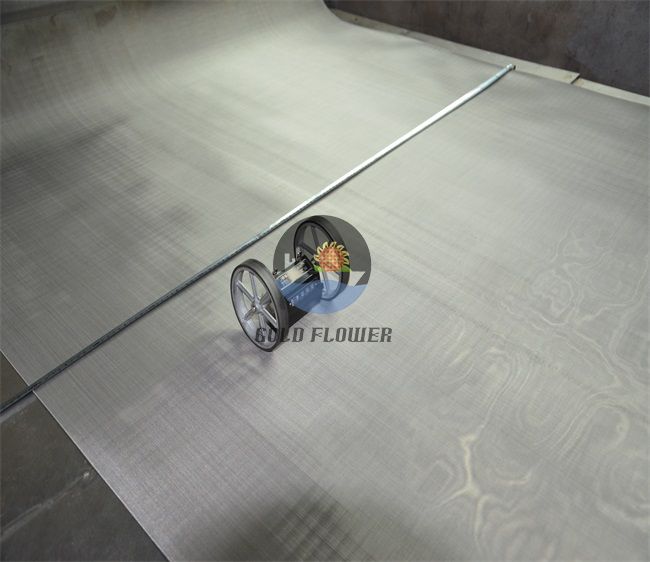

oem wire mesh aluminum

The Versatility of OEM Wire Mesh Aluminum A Comprehensive Overview

In today's industrial landscape, the demand for durable, lightweight, and versatile materials has driven manufacturers to explore various options. One such innovative product is OEM wire mesh aluminum, a favored choice for various applications across multiple sectors. By understanding its characteristics, benefits, and uses, we can appreciate why this material has gained significant traction in modern manufacturing.

What is OEM Wire Mesh Aluminum?

OEM wire mesh aluminum refers to a customized wire mesh product made from aluminum, tailored specifically to the needs of Original Equipment Manufacturers (OEMs). The term wire mesh indicates a grid-like structure formed from interwoven strands of metal. Aluminum, known for its lightweight and corrosion-resistant properties, enhances the performance and lifespan of wire mesh products. OEM specifications ensure that these materials meet specific standards and requirements, allowing for greater adaptability to various applications.

Characteristics of OEM Wire Mesh Aluminum

1. Lightweight One of the most significant advantages of aluminum is its low density. OEM wire mesh aluminum is much lighter than other metal options like steel, making it easier to handle and transport.

2. Corrosion Resistance Aluminum naturally forms a protective oxide layer, which prevents rust and corrosion, even in harsh environments. This property is particularly beneficial in outdoor applications or industries that require exposure to chemicals or moisture.

3. Strength-to-Weight Ratio Despite being lightweight, aluminum possesses a high strength-to-weight ratio. This characteristic makes OEM wire mesh aluminum suitable for applications where strength and durability are crucial yet requires minimal weight.

4. Customizability As an OEM product, wire mesh aluminum can be tailored to meet specific design requirements, including varying mesh sizes, wire thicknesses, and finish options. This flexibility allows manufacturers to meet diverse demands across industries.

5. Aesthetic Appeal Aluminum can be finished in various ways, offering both functional and decorative solutions. Anodizing, painting, or coating the wire mesh can enhance its appearance and extend its life, making it an attractive choice for architectural designs.

oem wire mesh aluminum

Applications of OEM Wire Mesh Aluminum

The versatility of OEM wire mesh aluminum means it can be found in many sectors, including

1. Construction Aluminum wire mesh is commonly used in construction for reinforcing concrete, providing stability while minimizing weight. It is also employed in architectural features such as facades, railings, and screens.

2. Automotive In the automotive industry, OEM wire mesh aluminum is used for filters, screens, and grilles. Its lightweight nature helps improve fuel efficiency while maintaining necessary structural integrity.

3. Food and Beverage The corrosion resistance and easy-to-clean properties make aluminum wire mesh ideal for applications in food processing and packaging. It is often used in conveyor systems and filtration processes.

4. Aerospace The aerospace sector demands materials that are not only strong but also lightweight. OEM wire mesh aluminum components are used in various applications, including airframes and components of aircraft.

5. Electronics In electronics, this material can be found in shielding applications, protecting sensitive components from electromagnetic interference while remaining lightweight.

Conclusion

OEM wire mesh aluminum stands as a testament to the innovative materials that drive modern manufacturing. Its unique combination of lightweight, strength, corrosion resistance, and customizability makes it a preferred choice across diverse industries. As technology advances and industries evolve, the application of OEM wire mesh aluminum is likely to expand further, leading to new uses that enhance efficiency and performance. For businesses looking to source high-quality aluminum wire mesh tailored to their specific needs, understanding the benefits and applications of this versatile material is the first step towards making informed decisions in their manufacturing processes. Whether enhancing construction projects, improving vehicle performance, or ensuring food safety, OEM wire mesh aluminum is poised to play a crucial role in the future of materials technology.

share

-

Metal Fly Curtains Durable Insect Barrier & Ventilation Solution

NewsMay.15,2025

-

ODM Steel Crimped Mesh High-Strength & Customizable Solutions

NewsMay.15,2025

-

Wire Mesh Filter Elements Durable & Affordable Filtration Solutions

NewsMay.14,2025

-

Professional Chain Link Fence Installation Services Fast & Affordable

NewsMay.14,2025

-

Premium Dutch Woven Wire Cloth Exporter Durable & Versatile Solutions

NewsMay.13,2025

-

Best Galvanized Wire Mesh for Gabion Baskets OEM & Durable

NewsMay.13,2025