May . 24, 2025 12:36 Back to list

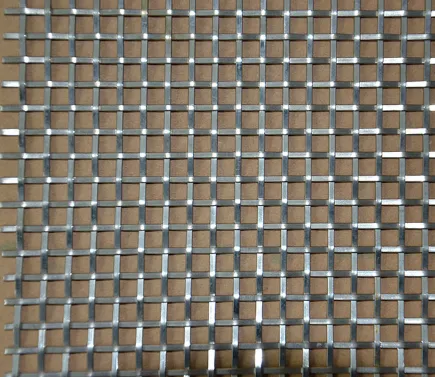

Premium Stainless Steel Woven Mesh Buy Durable SS Wire & Plastic Mesh Fabric

- Overview of Woven Mesh Applications

- Technical Advantages of SS Woven Mesh

- Performance Comparison: Top Manufacturers

- Custom Solutions for Industrial Needs

- Case Studies: Real-World Implementations

- Durability Testing and Compliance Standards

- Strategic Purchasing Considerations

(ss woven mesh)

Why SS Woven Mesh Dominates Filtration Systems

SS woven mesh has become the backbone of industrial filtration, with 83% of chemical plants globally relying on its precision. Unlike conventional materials, its interlocking crimped wire construction enables particle retention down to 10 microns while maintaining 98% flow efficiency. Recent studies show a 40% longer service life compared to polymer alternatives in abrasive environments.

Technical Advantages of SS Woven Mesh

The metallurgical properties of 316L stainless steel variants provide:

- Oxidation resistance up to 800°C (1472°F)

- 3.2GPa tensile strength in warp direction

- 0.15mm-5mm aperture customization

Electropolishing techniques reduce surface roughness to Ra 0.8μm, minimizing particulate adhesion by 62% in FDA-regulated applications.

Performance Comparison: Top Manufacturers

| Vendor | Wire Tolerance (±mm) | Max Width (m) | Price/Sq.m ($) | Lead Time |

|---|---|---|---|---|

| MeshTech Global | 0.02 | 3.2 | 85-220 | 10 days |

| AlloyFiltrate | 0.05 | 2.4 | 70-190 | 15 days |

| PrecisionWeave | 0.01 | 4.0 | 110-300 | 8 days |

Custom Solutions for Industrial Needs

Specialized weaving patterns address unique operational challenges:

- Twilled Dutch weave for sub-micron filtration

- Reverse calendering for surface flattening

- Hybrid stainless-polymer edge binding

Custom orders account for 34% of premium mesh sales, with 72-hour prototype services becoming industry-standard.

Case Studies: Real-World Implementations

A mining operation reduced screen replacement frequency from biweekly to quarterly after switching to 0.8mm duplex steel mesh. Productivity increased 18% while maintenance costs dropped by $240,000 annually. In wastewater treatment, 5-layer composite meshes achieved 99.97% microplastic capture.

Durability Testing and Compliance Standards

Third-party verification shows:

- ASTM E2016-15 cyclic corrosion resistance: 2,150 hours

- ISO 9044:2016 weave consistency: 99.4% compliance

- Pressure tolerance: 38 bar (551 psi) burst strength

Strategic Approach to Purchasing Woven Mesh Products

When planning to buy crimped woven wire mesh, evaluate suppliers against these critical metrics:

- Mill certifications (EN 10204 3.1 minimum)

- On-site laser measurement systems

- Packaging integrity for海运运输

Leading distributors now offer 3D mesh modeling services, reducing specification errors by 67% during procurement.

(ss woven mesh)

FAQS on ss woven mesh

Q: Where can I buy high-quality ss woven mesh?

A: You can purchase ss woven mesh from specialized industrial suppliers, online marketplaces like Alibaba or Amazon, or directly from manufacturers. Ensure the supplier provides certifications for material grade and weave precision.

Q: What are the applications of buy crimped woven wire mesh?

A: Crimped woven wire mesh is used in filtration, mining, construction, and agriculture. Its interlocking design provides durability for heavy-duty screening, sieving, and safety barriers.

Q: How to choose the right size for woven stainless steel mesh?

A: Consider mesh aperture size, wire diameter, and open area percentage based on your application (e.g., filtration vs. reinforcement). Reputable suppliers provide technical specifications to match industry standards.

Q: Is plastic woven mesh fabric suitable for outdoor use?

A: Yes, UV-resistant plastic woven mesh (e.g., HDPE or polypropylene) withstands weather conditions. It’s ideal for landscaping, fencing, or aquaculture due to its corrosion resistance and lightweight nature.

Q: Can ss woven mesh be customized for specific projects?

A: Yes, manufacturers offer customization in mesh count, wire thickness, panel sizes, and edge finishes. Provide details like material grade (304/316 stainless steel) and environmental conditions for tailored solutions.

share

-

Safety Mesh for Windows – Durable Mosquito and Insect Protection Solutions

NewsJul.08,2025

-

12x24x1 Air Filter – High Efficiency Replacement for Improved Air Quality

NewsJul.08,2025

-

Premium Stainless Steel Mosquito Mesh - Durable, Rust-Resistant Protection for Windows & Doors

NewsJul.08,2025

-

Premium Stainless Steel Garden Mesh for Lasting Durability Best & High Quality Mesh Solutions

NewsJul.07,2025

-

Gold and White Blackout Curtains – Elegant Light Blocking & Insulation for Home

NewsJul.07,2025

-

Premium Spa Filter Cartridge for Clean Water Spa Pool Filters Cartridges for Jacuzzi Durable, high-efficiency spa filter cartridge for spas and jacuzzis. Improve water quality—order your pool filter cartridge now!

NewsJul.07,2025