helmi . 14, 2025 03:02 Back to list

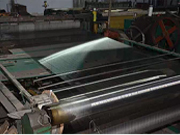

ce certification fine metal mesh netting

Metal netting mesh is an indispensable component in various industries, including agriculture, construction, and manufacturing. Understanding its diverse applications and the nuances of its selection can significantly influence both efficiency and durability in projects. With years of hands-on experience in project design and implementation, I am keen to share insights that underscore expertise in optimizing the use of metal netting mesh.

Another critical aspect of utilizing metal mesh correctly is the method of installation. Experience has shown that improper installation can lead to premature wear and increased maintenance costs. The use of correct fastening techniques and ensuring the mesh’s tension is adequately maintained are crucial steps in maximizing product lifespan. It is recommended to consult with professionals who bring specialized skills to this area, ensuring that the mesh is used to its fullest potential. Trustworthiness is built from proven results and consistent performance over time. Investing in high-quality metal netting mesh not only promises enhanced operational efficiency but also solidifies trust among clients and stakeholders. End-users should review case studies and client testimonials that highlight the mesh's successful applications in similar scenarios. Trust is further cemented when suppliers offer warranty and after-sale services, demonstrating a commitment to customer satisfaction. In the current market, the sustainability aspect of materials cannot be overlooked. Opting for recyclable and environmentally friendly metal netting meshes not only aligns with global trends towards sustainability but also attracts environmentally conscious stakeholders and clients. This approach not only underscores a commitment to the planet but also enhances the marketability of products or services associated with the mesh. In conclusion, the selection and application of metal netting mesh is a sophisticated process that benefits immensely from expert guidance. Whether the aim is to protect, support, or enhance structural components, a well-informed decision will invariably lead to cost benefits and superior project outcomes. By considering factors such as material type, standard compliance, and proper installation techniques, stakeholders can leverage the full potential of metal netting meshes, thereby ensuring their projects are both efficient and resilient. These insights, rooted in extensive experience and a commitment to quality, serve as a roadmap for utilizing metal netting mesh in the most effective way possible.

Another critical aspect of utilizing metal mesh correctly is the method of installation. Experience has shown that improper installation can lead to premature wear and increased maintenance costs. The use of correct fastening techniques and ensuring the mesh’s tension is adequately maintained are crucial steps in maximizing product lifespan. It is recommended to consult with professionals who bring specialized skills to this area, ensuring that the mesh is used to its fullest potential. Trustworthiness is built from proven results and consistent performance over time. Investing in high-quality metal netting mesh not only promises enhanced operational efficiency but also solidifies trust among clients and stakeholders. End-users should review case studies and client testimonials that highlight the mesh's successful applications in similar scenarios. Trust is further cemented when suppliers offer warranty and after-sale services, demonstrating a commitment to customer satisfaction. In the current market, the sustainability aspect of materials cannot be overlooked. Opting for recyclable and environmentally friendly metal netting meshes not only aligns with global trends towards sustainability but also attracts environmentally conscious stakeholders and clients. This approach not only underscores a commitment to the planet but also enhances the marketability of products or services associated with the mesh. In conclusion, the selection and application of metal netting mesh is a sophisticated process that benefits immensely from expert guidance. Whether the aim is to protect, support, or enhance structural components, a well-informed decision will invariably lead to cost benefits and superior project outcomes. By considering factors such as material type, standard compliance, and proper installation techniques, stakeholders can leverage the full potential of metal netting meshes, thereby ensuring their projects are both efficient and resilient. These insights, rooted in extensive experience and a commitment to quality, serve as a roadmap for utilizing metal netting mesh in the most effective way possible.

share

Next:

Latest news

-

CE Certification Metal Fine Mesh for Safety & Durability

NewsJul.24,2025

-

High-Efficiency Particle Filter for Superior Air Purification

NewsJul.23,2025

-

CE Certification 250 Micron Stainless Steel Mesh for Industrial Use

NewsJul.22,2025

-

CE Certified 250 Micron Stain Steel Mesh - Durable & Safe

NewsJul.21,2025

-

CE Certified 250 Micron Stainless Steel Mesh - High Durability & CE Approved

NewsJul.21,2025

-

Premium Slope Collapse Protection Mesh | Durable & Effective

NewsJul.20,2025