loka . 09, 2024 14:04 Back to list

high quality wire netting machine

High-Quality Wire Netting Machine Revolutionizing Modern Manufacturing

In today's fast-paced industrial landscape, efficiency and quality are paramount. The demand for high-quality wire netting machines has surged in recent years, driven by the increasing need for durable and versatile wire products in various sectors including construction, agriculture, and manufacturing. This article delves into the significance, features, and benefits of investing in high-quality wire netting machines.

Understanding Wire Netting Machines

A wire netting machine is specialized equipment designed to produce wire mesh products used for fencing, protection, and a variety of applications. These machines can handle different types of wire, including galvanized, stainless steel, and PVC-coated options, allowing for a range of final products like fencing, partitions, and even intricate decorative mesh designs. The primary function of these machines is to weave or weld wire strands together to form a strong, reliable netting structure.

The Importance of Quality

Quality is a critical factor when it comes to manufacturing wire netting. A high-quality wire netting machine ensures that the final products not only meet industry standards but also hold up against environmental stressors, wear, and tear. Investing in a machine that guarantees precision and consistency in production can significantly reduce waste, minimize repairs, and enhance customer satisfaction.

Key Features of High-Quality Wire Netting Machines

1. Durability and Build Quality High-quality machines are constructed with robust materials that can withstand heavy-duty use. This not only extends the life of the equipment but also ensures consistent performance over time.

2. Advanced Technology The latest models come equipped with cutting-edge technologies such as programmable logic controllers (PLCs), automatic feeding systems, and touch-screen interfaces. These features enhance operational efficiency and require less manual intervention, allowing for faster production cycles.

3. Versatility Quality machines can produce various mesh types, from fine netting for agricultural applications to heavy-duty fencing suitable for construction sites. This adaptability makes them vital for businesses that require diverse wire mesh products.

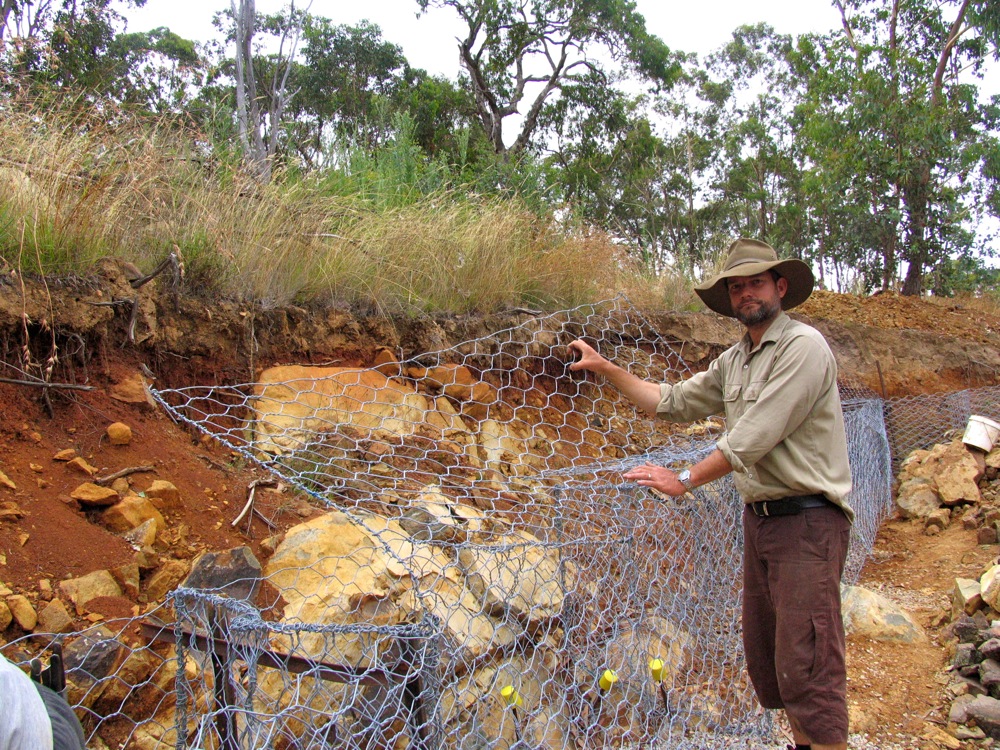

high quality wire netting machine

4. Energy Efficiency With growing concerns over environmental impact and energy costs, many high-quality wire netting machines are designed to be energy-efficient. They often utilize variable speed drives and energy recovery systems that reduce electricity consumption without compromising performance.

5. Ease of Maintenance High-quality machines are designed with user-friendliness in mind. Features such as modular components and easy access for repairs contribute to lower downtime and more efficient maintenance practices.

Benefits of Investing in High-Quality Wire Netting Machines

1. Increased Productivity The advanced technology and automation features in high-quality wire netting machines significantly enhance production rates. Businesses can meet growing demand without sacrificing quality.

2. Cost-Effectiveness Although the initial investment may be higher, the long-term savings associated with reduced maintenance, less downtime, and improved efficiency make these machines a cost-effective choice.

3. Improved Product Quality Machines that provide precise adjustments and consistent performance lead to superior product quality, which can help businesses maintain a competitive edge in the market.

4. Enhanced Safety Quality wire netting machines often incorporate safety features that protect operators, reducing the risk of accidents in the workplace.

5. Support for Sustainable Practices By reducing waste and improving energy efficiency, high-quality wire netting machines align with sustainable manufacturing practices, helping companies to fulfill their corporate social responsibility goals.

Conclusion

In conclusion, high-quality wire netting machines are indispensable in today’s manufacturing environment. Their advanced features, durability, and ability to produce versatile products not only cater to the diverse needs of industries but also support businesses in achieving efficiency and sustainability. As the market continues to evolve, investing in these machines will undeniably pave the way for improved manufacturing processes and product quality, ensuring that businesses remain competitive in a challenging economy. Making the right choice now will pay dividends in the future, setting the foundation for long-lasting success in wire netting production.

share

-

High-Quality Screen Stone for Modern Stone Screen Walls Elegant Facade Solutions

NewsJun.10,2025

-

High Quality Wire Filter – Cheap Stainless Steel Filter Wire Mesh Cloth & Wire Mesh Filter Solutions

NewsJun.10,2025

-

5 Micron Water Filter Cartridge - Premium Sediment Filtration, Universal Fit

NewsJun.10,2025

-

High Quality CE-Certified Gabion Boxes with OEM Options

NewsJun.10,2025

-

20x20x2 Air Filter High-Efficiency Dust Filtration for Clean Air

NewsJun.10,2025

-

Decorative Metal Mesh for Radiator Covers Custom Durable Mesh Panels

NewsJun.10,2025