marras . 04, 2024 23:38 Back to list

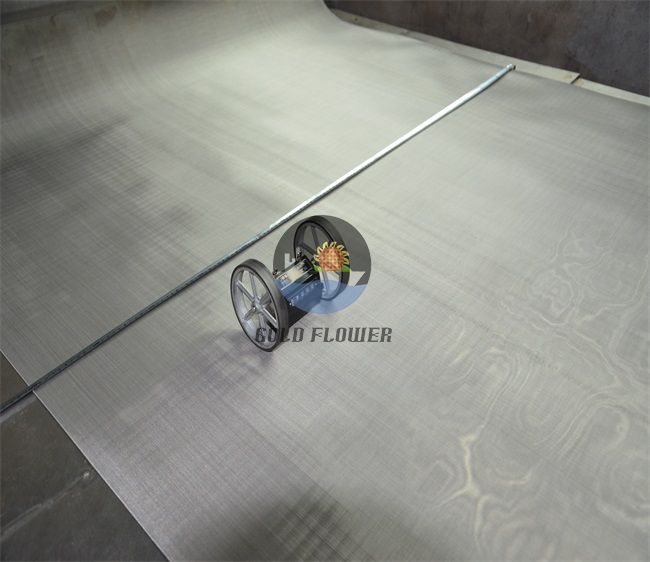

odm steel woven wire cloth

Understanding ODM Steel Woven Wire Cloth A Comprehensive Overview

In the realm of industrial applications, materials that offer strength, durability, and versatility are paramount. One such material that has gained significant attention is ODM steel woven wire cloth. This specialized mesh is quintessential in various sectors, from construction and mining to filtration and agricultural processes. This article will delve into what ODM steel woven wire cloth is, its characteristics, uses, and key factors to consider when selecting this material.

What is ODM Steel Woven Wire Cloth?

ODM stands for Original Design Manufacturer, which often implies a product that meets specific design and quality standards set by the manufacturer. In the case of steel woven wire cloth, this term underscores its reliability and tailored application in various fields.

Steel woven wire cloth is made by interlacing stainless steel wires in a grid pattern, providing a sturdy and flexible material designed for multifarious uses. The weaving process allows for different weave types—such as plain, twill, and Dutch weave—each suited to specific applications and requirements.

Characteristics of ODM Steel Woven Wire Cloth

1. Durability One of the standout features of steel woven wire cloth is its incredible durability. The resilient nature of steel allows the cloth to withstand heavy loads and resist wear and tear over time.

2. Corrosion Resistance Depending on the type of steel used, many ODM wire cloths come with enhanced resistance to corrosion, which is essential in industries where exposure to moisture and various chemicals is inevitable.

3. Versatility ODM steel woven wire cloth is available in a wide range of specifications. The mesh size can be customized to meet specific filtration needs, making it valuable across diverse applications.

4. Aesthetic Appeal While functionality is critical, the aesthetic aspect of the woven wire cloth cannot be overlooked. It can provide a modern look in architectural applications and can be finished in various ways to enhance its visual appeal.

Applications of ODM Steel Woven Wire Cloth

odm steel woven wire cloth

1. Filtration One of the primary uses of ODM steel woven wire cloth is in filtration processes. It is employed to separate solid particles from liquids or gases in various industries, including water treatment, pharmaceuticals, and food processing.

2. Construction In the construction industry, this steel mesh is used in concrete reinforcement, providing added strength to structures and enhancing their lifespan.

3. Mining and Aggregate The mining industry also benefits from ODM steel woven wire cloth, specifically for sorting materials and ensuring the efficient processing of minerals and aggregates.

4. Agriculture In agriculture, the cloth is part of pest control systems and is used in fencing and barriers, promoting the health of crops and livestock.

5. Decorative Applications Beyond industrial uses, ODM steel woven wire cloth can also be utilized in decorative applications such as partitions, railing infills, and architectural features, blending practicality with design.

Selecting the Right ODM Steel Woven Wire Cloth

When choosing ODM steel woven wire cloth, consider the following factors

- Mesh Size The specific application will dictate the required mesh size. Whether separating fine particles or creating sturdy fencing, the mesh size is crucial. - Wire Diameter The thickness of the wire impacts the cloth’s strength and flexibility. Different applications may require varying wire diameters.

- Material Composition Determine if a standard steel, stainless steel, or other alloy is needed, particularly if corrosion resistance is a concern.

- Weaving Type Based on application, choose the appropriate weave type to ensure optimal performance and durability.

In conclusion, ODM steel woven wire cloth stands as a valuable asset in numerous industries. Its unique blend of strength, durability, and versatility makes it a go-to material for various applications. Understanding its characteristics, uses, and selection criteria will empower buyers to make informed decisions, ensuring they achieve the best results for their specific needs.

share

-

CE Certified 250 Micron Stainless Steel Filter Mesh | Premium

NewsJul.31,2025

-

CE Certified 250 Micron Stainless Steel Mesh | Premium Filter

NewsJul.31,2025

-

CE Certification Buy Wire Mesh Fence for High Security and Durability

NewsJul.30,2025

-

Stainless Steel Mesh Filter Discs for Precise Filtration Solutions

NewsJul.29,2025

-

CE Certification 250 Micron Stainless Steel Mesh for Industrial Use

NewsJul.29,2025

-

Premium Stainless Steel Weave Mesh for Filtration and Security

NewsJul.29,2025