joulu . 09, 2024 17:35 Back to list

Custom Metal Wire Mesh Solutions for Various Applications and Industries.

The Versatility and Applications of OEM Metal Wire Netting

In contemporary manufacturing and construction industries, materials that offer flexibility, strength, and durability are highly sought after. One such material is metal wire netting, particularly when it is produced through Original Equipment Manufacturer (OEM) processes. The OEM approach facilitates the customization and production of metal wire nets that meet specific requirements for various applications. This article will explore the features, benefits, and wide-ranging uses of OEM metal wire netting.

Metal wire netting is crafted from different types of metals, including stainless steel, aluminum, and galvanized iron. This variety allows for a multitude of applications, from industrial settings to household uses. The primary advantage of metal wire net is its incredible strength-to-weight ratio, making it suitable for use in demanding environments where durability is paramount. Additionally, the manufacturing process can be tailored to create nets with varying mesh sizes, wire thicknesses, and coatings that enhance resistance to corrosion and wear.

The Versatility and Applications of OEM Metal Wire Netting

The applications of OEM metal wire netting are vast. In agriculture, it serves as fencing, trellising, and crop protection, effectively guarding plants while allowing sunlight and rain to nurture them. The flexibility of these nets enables farmers to create innovative cultivation systems that enhance productivity and efficiency.

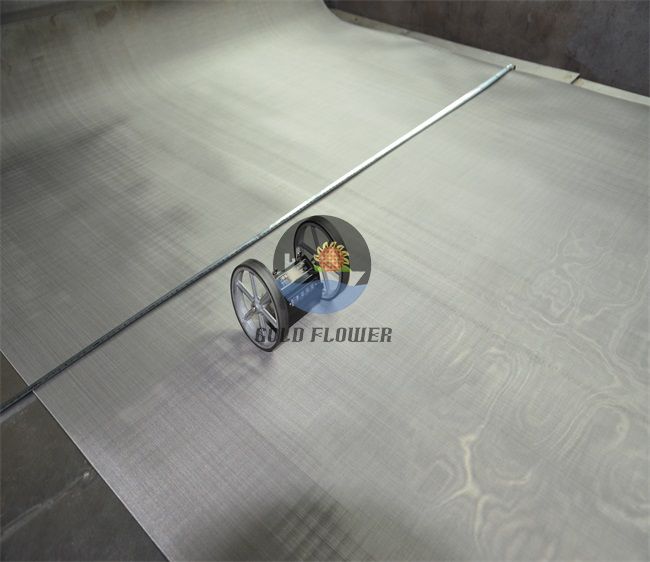

oem metal wire net

In industrial settings, metal wire nets are commonly used for safety barriers, shelving units, and storage solutions. They can effectively enclose machinery, safeguarding workers from potential hazards while maintaining visibility and airflow. The construction industry also frequently employs metal wire netting, particularly for reinforcing concrete structures. Used as a grid, it adds tensile strength to concrete, ensuring that buildings and other constructions maintain their integrity over time.

Moreover, metal wire netting is prevalent in the architectural field. Designers utilize it not only for functional purposes but also for aesthetic enhancements. For example, architecturally finished wire mesh can create stunning facades, allowing light to filter through while providing privacy and security.

In terms of environmental sustainability, OEM metal wire netting is a favorable choice. Many manufacturers utilize recyclable materials in their production processes, promoting a circular economy. Furthermore, metal wire nets tend to have a longer lifespan compared to plastic counterparts, reducing waste over time.

In conclusion, OEM metal wire netting is an invaluable resource in various industries due to its versatility, strength, and customizability. From agriculture to construction, its applications are extensive and growing. By collaborating with OEM manufacturers, clients can develop solutions tailored to their precise needs, ensuring functionality while also emphasizing sustainability. As industries continue to evolve, the demand for durable, high-quality materials like OEM metal wire netting will undoubtedly remain strong, reinforcing its position as a staple in modern manufacturing and construction.

share

-

CE Certified 250 Micron Stainless Steel Mesh Filter

NewsAug.04,2025

-

Premium Twill Weave Mesh for Industrial Filtration & Strength

NewsAug.03,2025

-

CE Certified 250 Micron Stainless Steel Mesh - Durable Filter

NewsAug.02,2025

-

CE Certified 250 Micron Stainless Steel Filter Mesh | Premium

NewsJul.31,2025

-

CE Certified 250 Micron Stainless Steel Mesh | Premium Filter

NewsJul.31,2025

-

CE Certification Buy Wire Mesh Fence for High Security and Durability

NewsJul.30,2025