tammi . 09, 2025 14:08 Back to list

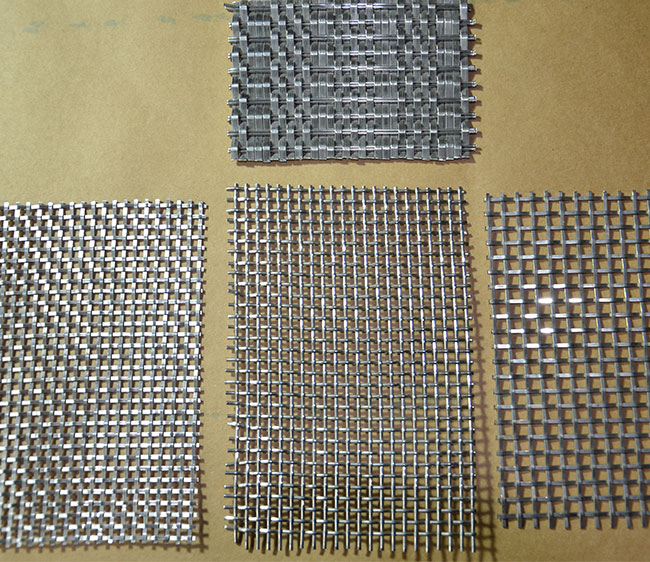

wire net

Wire netting, a versatile product with a myriad of applications, has gained traction across various industries due to its robust and adaptable nature. Made from metals such as galvanized steel, stainless steel, or aluminum, wire netting serves as a fundamental component in sectors ranging from agriculture to construction.

Beyond industrial uses, wire netting finds a place in artistic endeavors and architectural design. Artists leverage its flexible structure to craft intricate sculptures and installations, exploiting its balance between strength and pliability. Architects incorporate wire netting into building facades and interior design, adding aesthetic appeal while simultaneously providing practical functions such as light diffusion or security screening. The fishing and aquaculture industries equally benefit from wire netting, utilizing it for making reliable nets and cages essential for both harvesting and breeding purposes. Its resistance to corrosion, especially when made from stainless steel, ensures longevity and consistent performance even in the harsh marine environment, thereby maximizing operational efficiency and yield for fishermen and aquaculture farmers. In mining, wire netting is used to stabilize slopes and prevent rockfall, protecting infrastructures and workers from potential hazards. Known for its tensile strength, it provides an unparalleled safety measure in an industry where stability and security are paramount. Moreover, the ease of installation and maintenance makes wire netting a cost-effective option for long-term projects. The multi-functional benefits of wire netting underscore its importance across diverse fields, making it an essential material in both contemporary and traditional applications. Its adaptability not only meets the evolving demands of various industries but also guarantees an efficient solution with reliability, cost-effectiveness, and environmental consciousness. Looking forward, the wire net's role is poised to expand, driven by technological advancements and increased demand for multipurpose materials that align with sustainability and innovation.

Beyond industrial uses, wire netting finds a place in artistic endeavors and architectural design. Artists leverage its flexible structure to craft intricate sculptures and installations, exploiting its balance between strength and pliability. Architects incorporate wire netting into building facades and interior design, adding aesthetic appeal while simultaneously providing practical functions such as light diffusion or security screening. The fishing and aquaculture industries equally benefit from wire netting, utilizing it for making reliable nets and cages essential for both harvesting and breeding purposes. Its resistance to corrosion, especially when made from stainless steel, ensures longevity and consistent performance even in the harsh marine environment, thereby maximizing operational efficiency and yield for fishermen and aquaculture farmers. In mining, wire netting is used to stabilize slopes and prevent rockfall, protecting infrastructures and workers from potential hazards. Known for its tensile strength, it provides an unparalleled safety measure in an industry where stability and security are paramount. Moreover, the ease of installation and maintenance makes wire netting a cost-effective option for long-term projects. The multi-functional benefits of wire netting underscore its importance across diverse fields, making it an essential material in both contemporary and traditional applications. Its adaptability not only meets the evolving demands of various industries but also guarantees an efficient solution with reliability, cost-effectiveness, and environmental consciousness. Looking forward, the wire net's role is poised to expand, driven by technological advancements and increased demand for multipurpose materials that align with sustainability and innovation.

share

Next:

Latest news

-

CE Certification 250 Micron Stainless Steel Mesh for Industrial Use

NewsJul.22,2025

-

CE Certified 250 Micron Stain Steel Mesh - Durable & Safe

NewsJul.21,2025

-

CE Certified 250 Micron Stainless Steel Mesh - High Durability & CE Approved

NewsJul.21,2025

-

Premium Slope Collapse Protection Mesh | Durable & Effective

NewsJul.20,2025

-

Safety Mesh for Windows – Durable Mosquito and Insect Protection Solutions

NewsJul.08,2025

-

12x24x1 Air Filter – High Efficiency Replacement for Improved Air Quality

NewsJul.08,2025