Fév . 14, 2025 19:38 Back to list

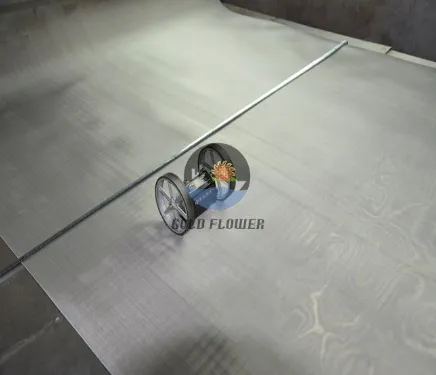

Gas Filtration SS Wire Mesh

Woven stainless steel has emerged as an invaluable material across various industries due to its exceptional properties, including high tensile strength, corrosion resistance, and versatility. Ideal for applications ranging from architectural design to industrial settings, buying woven stainless steel requires an understanding of its technical nuances and practical applications to optimize its use and maximize investment. Here's an insightful exploration on how to navigate your purchase of woven stainless steel with an emphasis on expertise, authority, and trustworthiness.

Navigating Price and Value While woven stainless steel represents a significant investment, it's crucial to balance cost with value. A lower upfront price might equate to increased susceptibility to wear and tear or inferior performance over time. Consider the lifecycle cost and potential maintenance savings when opting for higher-grade materials. Bundling purchases or establishing long-term contracts with suppliers can also offer cost benefits without compromising quality. Practical Applications and Techniques Woven stainless steel is extensively utilized in industries such as petrochemicals, food processing, and construction. In food processing, it serves as a critical component in sieving and filtration systems, where its resistance to chemicals and hygiene is paramount. In construction, it enhances not only the aesthetic value of buildings but also their functional resilience against the elements. For effective use, understanding the installation techniques is crucial. Whether it's tensioning for architectural purposes or fastening for industrial use, improper installation can undermine the mesh's performance. Engaging skilled professionals or obtaining equipment tailored for specific installation needs is advised to maintain the structural integrity of the stainless steel weave. Maintenance and Longevity Once installed, woven stainless steel's longevity can be maximized through regular maintenance. Despite its natural resistance to corrosion, periodic cleaning can prevent the buildup of residues that might impede its performance over time. Use environmentally friendly cleaning agents and ensure they are compatible with stainless steel to avoid surface damage. Regular inspections to assess wear and tear, especially in high-stress or corrosive environments, can preemptively identify issues before they escalate, ensuring prolonged performance. Conclusion Purchasing woven stainless steel is not just a transaction but a strategic investment in your operational efficiency and project success. By prioritizing expert guidance, adhering to quality standards, and maintaining the material meticulously, buyers can harness the full potential of this versatile material. Its benefits span across improving process efficiency, enhancing aesthetic appeal, and ensuring long-term reliability, making it an indispensable resource for various industries. Emphasizing professionalism and credibility at each purchase stage guarantees a rewarding experience and optimal return on investment.

Navigating Price and Value While woven stainless steel represents a significant investment, it's crucial to balance cost with value. A lower upfront price might equate to increased susceptibility to wear and tear or inferior performance over time. Consider the lifecycle cost and potential maintenance savings when opting for higher-grade materials. Bundling purchases or establishing long-term contracts with suppliers can also offer cost benefits without compromising quality. Practical Applications and Techniques Woven stainless steel is extensively utilized in industries such as petrochemicals, food processing, and construction. In food processing, it serves as a critical component in sieving and filtration systems, where its resistance to chemicals and hygiene is paramount. In construction, it enhances not only the aesthetic value of buildings but also their functional resilience against the elements. For effective use, understanding the installation techniques is crucial. Whether it's tensioning for architectural purposes or fastening for industrial use, improper installation can undermine the mesh's performance. Engaging skilled professionals or obtaining equipment tailored for specific installation needs is advised to maintain the structural integrity of the stainless steel weave. Maintenance and Longevity Once installed, woven stainless steel's longevity can be maximized through regular maintenance. Despite its natural resistance to corrosion, periodic cleaning can prevent the buildup of residues that might impede its performance over time. Use environmentally friendly cleaning agents and ensure they are compatible with stainless steel to avoid surface damage. Regular inspections to assess wear and tear, especially in high-stress or corrosive environments, can preemptively identify issues before they escalate, ensuring prolonged performance. Conclusion Purchasing woven stainless steel is not just a transaction but a strategic investment in your operational efficiency and project success. By prioritizing expert guidance, adhering to quality standards, and maintaining the material meticulously, buyers can harness the full potential of this versatile material. Its benefits span across improving process efficiency, enhancing aesthetic appeal, and ensuring long-term reliability, making it an indispensable resource for various industries. Emphasizing professionalism and credibility at each purchase stage guarantees a rewarding experience and optimal return on investment.

share

Next:

Latest news

-

CE Certified 250 Micron Stainless Steel Mesh Filter

NewsAug.04,2025

-

Premium Twill Weave Mesh for Industrial Filtration & Strength

NewsAug.03,2025

-

CE Certified 250 Micron Stainless Steel Mesh - Durable Filter

NewsAug.02,2025

-

Screen Mesh Price Deals | gpt-4-turbo Optimized Pricing

NewsAug.01,2025

-

CE Certified 250 Micron Stainless Steel Filter Mesh | Premium

NewsJul.31,2025

-

CE Certified 250 Micron Stainless Steel Mesh | Premium Filter

NewsJul.31,2025