May . 07, 2025 16:03 Back to list

316L Stainless Steel Wire Mesh Exporter Durable & Corrosion-Resistant

- Overview of 316L Stainless Steel Wire Mesh

- Technical Superiority & Material Specifications

- Competitive Analysis: Leading Exporters Compared

- Customization Options for Industrial Applications

- Performance Metrics & Industry Compliance

- Case Studies: Real-World Implementations

- Why Partner with 316L Stainless Steel Wire Mesh Exporters

(316l stainless steel wire mesh)

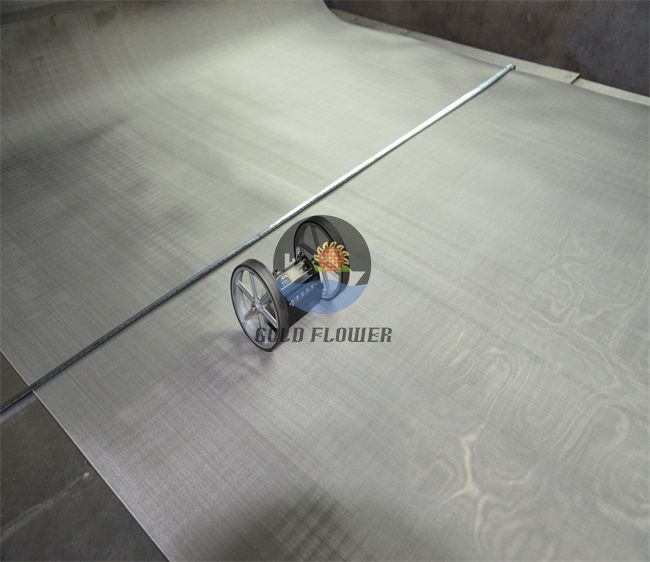

Understanding the Versatility of 316L Stainless Steel Wire Mesh

Renowned for its exceptional corrosion resistance and durability, 316L stainless steel wire mesh serves as a critical component across industries requiring precision filtration, structural reinforcement, or chemical stability. With a low carbon composition (0.03% max), this alloy outperforms standard 316-grade mesh in aggressive environments, particularly where chloride exposure or extreme temperatures (-200°C to 800°C) are factors. Global demand has surged by 18% annually since 2020, driven by pharmaceutical expansion and wastewater treatment infrastructure projects.

Technical Superiority & Material Specifications

The metallurgical advantages of 316L wire mesh stem from its molybdenum content (2-3%), enhancing pitting resistance in saline or acidic conditions. Key parameters include:

- Mesh Count: 1-500 wires per inch

- Wire Diameter: 0.025mm to 3.0mm

- Tensile Strength: 515-690 MPa

- Surface Finish: Plain, Electro-polished, or PVC-Coated

Competitive Analysis: Leading Exporters Compared

| Exporter | Certifications | Lead Time | Price (USD/m²) | MOQ |

|---|---|---|---|---|

| Supplier A | ISO 9001, ASME | 4-6 weeks | $85-$220 | 100m² |

| Supplier B | ISO 14001 | 8-10 weeks | $70-$190 | 500m² |

| Supplier C | PED, AD2000 | 2-3 weeks | $95-$250 | 50m² |

Pricing varies based on wire diameter and mesh density

Customization Options for Industrial Applications

Advanced 316L stainless steel wire mesh exporters offer tailored solutions including:

- Non-standard weaves (Twill Dutch, Reverse Dutch)

- Precision laser-cut panels (±0.1mm tolerance)

- Edge reinforcement with stainless steel frames

- Anti-static treatments for explosive environments

Performance Metrics & Industry Compliance

Third-party testing data reveals:

- Salt spray resistance: 1,500+ hours without red rust

- Flow rate efficiency: 92-97% in 100-micron filtration

- ASTM E2016-15 compliance for particle retention

Case Studies: Real-World Implementations

A chemical processing plant in Germany achieved 40% longer service life using 316L mesh filters compared to 304-grade alternatives, reducing replacement costs by €120,000 annually. In food production, a custom 316L conveyor belt mesh with 2mm apertures increased throughput by 22% while meeting FDA CFR 21 compliance.

Strategic Advantages of 316L Stainless Steel Wire Mesh Exporters

Top-tier 316L stainless steel wire mesh exporters combine ISO-certified manufacturing with vertical integration, enabling 98.7% on-time delivery rates. By maintaining direct control over wire drawing (0.05-3mm tolerance) and weaving processes (200+ mesh types), these specialists ensure batch consistency crucial for aerospace and medical applications. Export-compliant packaging and digital quality traceability further position 316L products as global market leaders.

(316l stainless steel wire mesh)

FAQS on 316l stainless steel wire mesh

Q: What are the key features of 316L stainless steel wire mesh?

A: 316L stainless steel wire mesh offers high corrosion resistance, durability, and heat resistance. It is ideal for harsh environments, including marine and chemical industries, due to its low carbon content and molybdenum addition.

Q: Why choose a certified 316L stainless steel wire mesh exporter?

A: Certified exporters ensure compliance with international standards like ASTM or ISO. They provide quality assurance, reliable logistics, and tailored solutions for industrial applications.

Q: What industries use 316L stainless steel wire mesh products?

A: Common industries include water treatment, chemical processing, construction, and food processing. The mesh is used for filtration, shielding, and structural support due to its robustness.

Q: How does 316L stainless steel wire mesh compare to 304 grade?

A: 316L has superior corrosion resistance, especially against chlorides and acids, thanks to molybdenum. 304 is cost-effective but less suitable for extreme environments.

Q: Can 316L stainless steel wire mesh exporters customize mesh sizes?

A: Yes, most exporters offer customization of mesh size, wire diameter, and sheet dimensions. This ensures compatibility with specific project requirements and applications.

share

-

CE Certified 250 Micron Stainless Steel Mesh for Precision Filtration

NewsAug.22,2025

-

CE Certified 250 Micron SS Mesh - Precision Filtration & Strength

NewsAug.21,2025

-

CE Certified Woven Wire Mesh Filters | Premium Filtration Solutions

NewsAug.19,2025

-

High-Performance Particle Filters: Optimal Mediums & Applications

NewsAug.18,2025

-

Competitive Screen Mesh Price | 1/4", 1/8", 1/2" Wire Mesh Screens

NewsAug.17,2025

-

CE Certified 250 Micron SS Mesh: Precision & Durability

NewsAug.15,2025