Jan . 11, 2025 10:29 Back to list

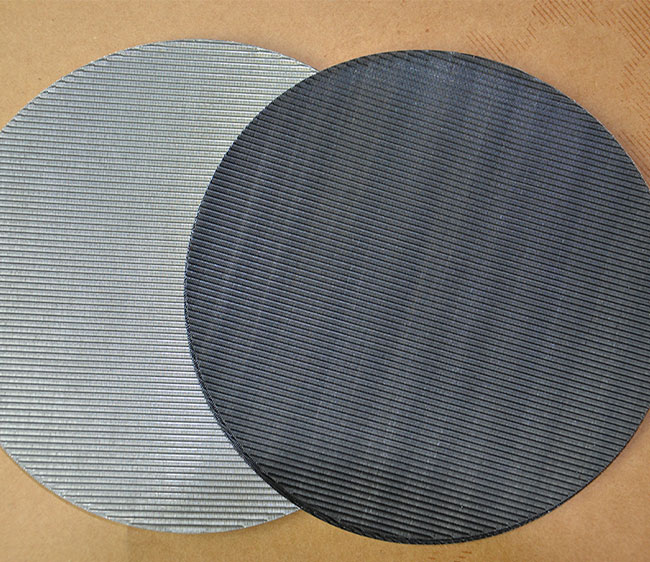

400 stainless steel mesh

Stainless steel mesh has emerged as a pivotal component in various industries, thanks to its unmatched durability, versatility, and reliability. When sourcing materials for applications ranging from architectural designs to industrial processes, stainless steel mesh stands out as a preferred choice.

Notably, the healthcare sector also benefits from the unique properties of stainless steel mesh. In medical environments where sterility, strength, and biocompatibility are of paramount importance, stainless steel mesh is employed in the production of surgical instruments, implants, and even hospital fixtures. Its use assures patients and professionals of the safety and effectiveness of medical procedures. For those involved in manufacturing and construction, the production of stainless steel mesh is well regulated, which in turn enhances its reputation. The quality control systems ensure that customers receive a product that meets international standards. This reliability is crucial for stakeholders who prioritize not just the performance but also the credibility of materials they use. Adhering to strict manufacturing guidelines, companies that produce stainless steel mesh offer an authoritative guarantee of quality to their clients. Furthermore, stainless steel mesh's recyclability highlights its environmental friendliness. In an era where sustainability is as important as performance, choosing materials that can be recycled without losing their inherent qualities is vital. By selecting stainless steel mesh, industries not only fulfill their operational needs but also contribute to global sustainability initiatives. In summary, stainless steel mesh is a cornerstone material catering to diverse industries with its robust properties, multifaceted applications, and assurance of quality. Whether for construction, industrial processing, healthcare, or environmental management, the expertise and trustworthiness associated with stainless steel mesh make it an unparalleled choice for professionals seeking efficiency, durability, and an edge in modern applications.

Notably, the healthcare sector also benefits from the unique properties of stainless steel mesh. In medical environments where sterility, strength, and biocompatibility are of paramount importance, stainless steel mesh is employed in the production of surgical instruments, implants, and even hospital fixtures. Its use assures patients and professionals of the safety and effectiveness of medical procedures. For those involved in manufacturing and construction, the production of stainless steel mesh is well regulated, which in turn enhances its reputation. The quality control systems ensure that customers receive a product that meets international standards. This reliability is crucial for stakeholders who prioritize not just the performance but also the credibility of materials they use. Adhering to strict manufacturing guidelines, companies that produce stainless steel mesh offer an authoritative guarantee of quality to their clients. Furthermore, stainless steel mesh's recyclability highlights its environmental friendliness. In an era where sustainability is as important as performance, choosing materials that can be recycled without losing their inherent qualities is vital. By selecting stainless steel mesh, industries not only fulfill their operational needs but also contribute to global sustainability initiatives. In summary, stainless steel mesh is a cornerstone material catering to diverse industries with its robust properties, multifaceted applications, and assurance of quality. Whether for construction, industrial processing, healthcare, or environmental management, the expertise and trustworthiness associated with stainless steel mesh make it an unparalleled choice for professionals seeking efficiency, durability, and an edge in modern applications.

share

Next:

Latest news

-

CE Certification Buy Wire Mesh Fence for High Security and Durability

NewsJul.30,2025

-

Stainless Steel Mesh Filter Discs for Precise Filtration Solutions

NewsJul.29,2025

-

CE Certification 250 Micron Stainless Steel Mesh for Industrial Use

NewsJul.29,2025

-

Premium Stainless Steel Weave Mesh for Filtration and Security

NewsJul.29,2025

-

CE Certification 250 Micron Stainless Steel Mesh for Safety & Durability

NewsJul.29,2025

-

Decorative Perforated Metal Panels & Sheets with Unique Patterns

NewsJul.28,2025