Feb . 16, 2025 02:00 Back to list

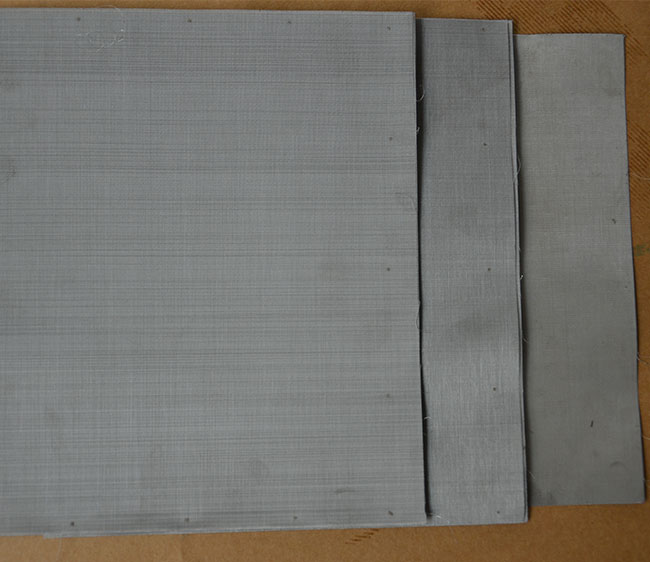

Woven Wire Drapery

In the bustling world of construction and industrial applications, buying the right industrial wire mesh can make the difference between the success and failure of a project. With decades of experience in the industry, I have witnessed firsthand how quality wire mesh can serve as the backbone of many structural applications. Here’s a comprehensive guide to understanding what makes industrial wire mesh an indispensable material and tips on how to smartly purchase it.

A common pitfall in purchasing wire mesh is overlooking the aspect of load-bearing capacity, especially in applications like walkways and platforms. Here, the thickness of the wire and the engineering behind the mesh structure come into play. Always consult an engineer to calculate the weight distribution and stress factors to choose a mesh that will not buckle under pressure. Many suppliers now offer computer-based modeling to predict performance under various conditions — a worthwhile investment for critical infrastructure. While cost is always a consideration, do not compromise quality for a lower price. An inexpensive mesh that fails prematurely can lead to increased maintenance costs and potential safety hazards, negating any initial savings. Instead, focus on suppliers who are ISO certified, as this is a testament to their commitment to quality and reliability in manufacturing. Seek out reviews or case studies from industries similar to yours; peer validation is a powerful tool in assessing both product and supplier legitimacy. To further bolster your purchasing strategy, inquire about the supplier's delivery capabilities and after-sales support. Swift delivery is crucial in preventing project delays, and competent technical support can aid in troubleshooting installation issues. Building a long-term relationship with a reliable supplier will ensure you receive consistent quality and possibly even better pricing for bulk purchases. Ultimately, industrial wire mesh is not just a product but an integral component that supports the integrity and success of a project. Through careful selection based on project-specific needs, consultation with experts, and partnership with reputable suppliers, you can ensure that you are investing in a product that will perform optimally and sustainably over time. Remember, the right wire mesh does more than meet operational needs — it provides peace of mind through quality and dependability.

A common pitfall in purchasing wire mesh is overlooking the aspect of load-bearing capacity, especially in applications like walkways and platforms. Here, the thickness of the wire and the engineering behind the mesh structure come into play. Always consult an engineer to calculate the weight distribution and stress factors to choose a mesh that will not buckle under pressure. Many suppliers now offer computer-based modeling to predict performance under various conditions — a worthwhile investment for critical infrastructure. While cost is always a consideration, do not compromise quality for a lower price. An inexpensive mesh that fails prematurely can lead to increased maintenance costs and potential safety hazards, negating any initial savings. Instead, focus on suppliers who are ISO certified, as this is a testament to their commitment to quality and reliability in manufacturing. Seek out reviews or case studies from industries similar to yours; peer validation is a powerful tool in assessing both product and supplier legitimacy. To further bolster your purchasing strategy, inquire about the supplier's delivery capabilities and after-sales support. Swift delivery is crucial in preventing project delays, and competent technical support can aid in troubleshooting installation issues. Building a long-term relationship with a reliable supplier will ensure you receive consistent quality and possibly even better pricing for bulk purchases. Ultimately, industrial wire mesh is not just a product but an integral component that supports the integrity and success of a project. Through careful selection based on project-specific needs, consultation with experts, and partnership with reputable suppliers, you can ensure that you are investing in a product that will perform optimally and sustainably over time. Remember, the right wire mesh does more than meet operational needs — it provides peace of mind through quality and dependability.

share

Next:

Latest news

-

CE Certified 250 Micron Stainless Steel Mesh Filter

NewsAug.04,2025

-

Premium Twill Weave Mesh for Industrial Filtration & Strength

NewsAug.03,2025

-

CE Certified 250 Micron Stainless Steel Mesh - Durable Filter

NewsAug.02,2025

-

Screen Mesh Price Deals | gpt-4-turbo Optimized Pricing

NewsAug.01,2025

-

CE Certified 250 Micron Stainless Steel Filter Mesh | Premium

NewsJul.31,2025

-

CE Certified 250 Micron Stainless Steel Mesh | Premium Filter

NewsJul.31,2025