Feb . 11, 2025 02:26 Back to list

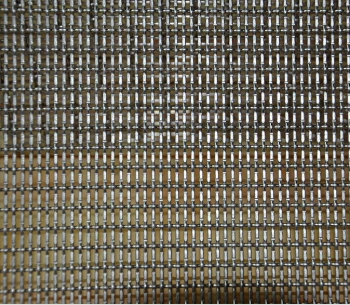

ce certification fine metal mesh netting

Navigating the world of metal mesh can be an overwhelming endeavor, especially for those who seek to buy very fine metal mesh for specialized applications. Having spent years immersed in the intricacies of metal materials and their various uses, I aim to provide a comprehensive guide that not only informs but also empowers you with the confidence needed to make an informed purchase.

Trustworthy suppliers often provide detailed insights into the testing and certification of their products. Look for those who adhere to international quality standards such as ASTM or ISO. These certifications go a long way in verifying the mesh's suitability for your specific needs, especially when the application is highly technical and precise. Building Trust through Experience Real-world testimonials and case studies from industries similar to yours can offer reassurance. If a particular metal mesh is praised for its performance in high-stakes environments, it can serve as a strong indicator of its potential reliability. A supplier with a robust portfolio of such case studies is more likely to be experienced and trustworthy. Sustainability and Environmental Impact An often overlooked but increasingly important aspect is the sustainability of the metal mesh production process. Environmentally conscious manufacturers who prioritize sustainability not only contribute to reducing the ecological footprint but also often adhere to stricter safety and quality standards. By choosing products from such sources, you align your purchase with values that transcend mere transactional relationships. Making the Purchase Decision Ultimately, buying very fine metal mesh is not merely about selecting a product based on specifications; it is about engaging with a supplier whose expertise, commitment to quality, and ethical practices align with your needs. Conducting due diligence by verifying supplier credentials, requesting samples, and engaging directly with their technical teams can greatly influence the success of your purchase. In conclusion, the quest to buy very fine metal mesh can be navigated successfully by emphasizing real-world experience, professional expertise, and credible authority. It is a process that involves understanding the unique specifications of the mesh, recognizing the importance of the application-specific requirements, examining the manufacturing process, and ensuring that the supplier upholds environmental and ethical standards. Such a holistic approach positions you as an informed buyer, equipped to make decisions that meet your industry’s demands while supporting sustainable practices.

Trustworthy suppliers often provide detailed insights into the testing and certification of their products. Look for those who adhere to international quality standards such as ASTM or ISO. These certifications go a long way in verifying the mesh's suitability for your specific needs, especially when the application is highly technical and precise. Building Trust through Experience Real-world testimonials and case studies from industries similar to yours can offer reassurance. If a particular metal mesh is praised for its performance in high-stakes environments, it can serve as a strong indicator of its potential reliability. A supplier with a robust portfolio of such case studies is more likely to be experienced and trustworthy. Sustainability and Environmental Impact An often overlooked but increasingly important aspect is the sustainability of the metal mesh production process. Environmentally conscious manufacturers who prioritize sustainability not only contribute to reducing the ecological footprint but also often adhere to stricter safety and quality standards. By choosing products from such sources, you align your purchase with values that transcend mere transactional relationships. Making the Purchase Decision Ultimately, buying very fine metal mesh is not merely about selecting a product based on specifications; it is about engaging with a supplier whose expertise, commitment to quality, and ethical practices align with your needs. Conducting due diligence by verifying supplier credentials, requesting samples, and engaging directly with their technical teams can greatly influence the success of your purchase. In conclusion, the quest to buy very fine metal mesh can be navigated successfully by emphasizing real-world experience, professional expertise, and credible authority. It is a process that involves understanding the unique specifications of the mesh, recognizing the importance of the application-specific requirements, examining the manufacturing process, and ensuring that the supplier upholds environmental and ethical standards. Such a holistic approach positions you as an informed buyer, equipped to make decisions that meet your industry’s demands while supporting sustainable practices.

share

Latest news

-

Premium Twill Weave Mesh for Industrial Filtration & Strength

NewsAug.03,2025

-

CE Certified 250 Micron Stainless Steel Mesh - Durable Filter

NewsAug.02,2025

-

Screen Mesh Price Deals | gpt-4-turbo Optimized Pricing

NewsAug.01,2025

-

CE Certified 250 Micron Stainless Steel Filter Mesh | Premium

NewsJul.31,2025

-

CE Certified 250 Micron Stainless Steel Mesh | Premium Filter

NewsJul.31,2025

-

CE Certification Buy Wire Mesh Fence for High Security and Durability

NewsJul.30,2025