Jan . 15, 2025 04:20 Back to list

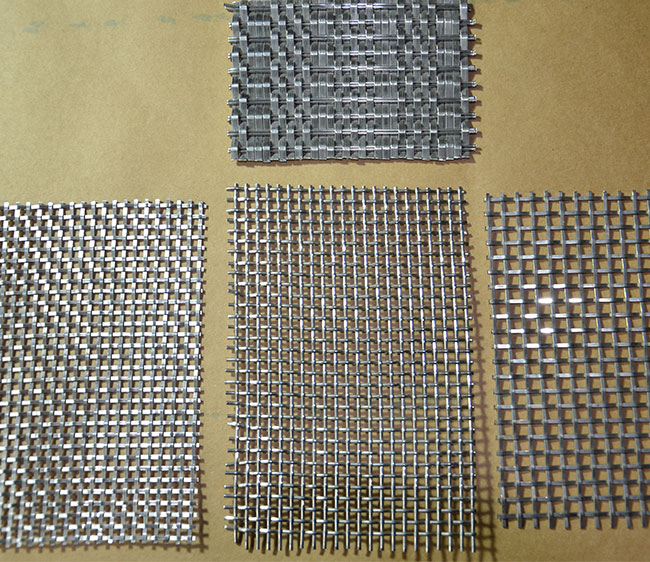

Oil water separation net

Purchasing a wire net machine can be an instrumental decision for businesses in the manufacturing and construction industries. Given the rise in industrial demands, wire mesh products are increasingly essential, be it for fencing, reinforcement, or filtering applications. The decision to invest in a wire net machine should be guided by a comprehensive understanding of both the technical specifications of the machines available and the credibility of the manufacturers.

Trustworthiness stems from transparency concerning machine specifications, warranty policies, and pricing structures. Reputable manufacturers should openly discuss the technical aspects of their machines, offering clarity on capabilities and limitations. A trustworthy supplier will ensure that all promises made regarding machine performance and customer service are backed by a documented guarantee. In addition to these considerations, future scalability should be part of your purchasing decision. The ideal wire net machine should offer options for upgrades or modifications as your business grows or pivots into new markets. This scalability not only protects your investment but also positions your company for dynamic growth in the ever-evolving industrial landscape. Understanding the adaptability of the machine to integrate with emerging technologies and additional features is crucial. Sustainability, while often overlooked, is also a significant aspect. Machines designed to minimize waste and operate efficiently contribute not only to environmental goals but also to cost-saving through reduced material usage and energy consumption. Look for machines built with environmentally-friendly processes and compliant with international safety and efficiency standards. In summary, selecting the right wire net machine involves a balance of understanding your technical needs, leveraging comprehensive support systems, and aligning with reputable manufacturers who offer transparency and innovation. Such an informed approach ensures your investment leads to enhanced productivity, reliability, and long-term growth for your business.

Trustworthiness stems from transparency concerning machine specifications, warranty policies, and pricing structures. Reputable manufacturers should openly discuss the technical aspects of their machines, offering clarity on capabilities and limitations. A trustworthy supplier will ensure that all promises made regarding machine performance and customer service are backed by a documented guarantee. In addition to these considerations, future scalability should be part of your purchasing decision. The ideal wire net machine should offer options for upgrades or modifications as your business grows or pivots into new markets. This scalability not only protects your investment but also positions your company for dynamic growth in the ever-evolving industrial landscape. Understanding the adaptability of the machine to integrate with emerging technologies and additional features is crucial. Sustainability, while often overlooked, is also a significant aspect. Machines designed to minimize waste and operate efficiently contribute not only to environmental goals but also to cost-saving through reduced material usage and energy consumption. Look for machines built with environmentally-friendly processes and compliant with international safety and efficiency standards. In summary, selecting the right wire net machine involves a balance of understanding your technical needs, leveraging comprehensive support systems, and aligning with reputable manufacturers who offer transparency and innovation. Such an informed approach ensures your investment leads to enhanced productivity, reliability, and long-term growth for your business.

share

Next:

Latest news

-

High-Efficiency Particle Filter for Superior Air Purification

NewsJul.23,2025

-

CE Certification 250 Micron Stainless Steel Mesh for Industrial Use

NewsJul.22,2025

-

CE Certified 250 Micron Stain Steel Mesh - Durable & Safe

NewsJul.21,2025

-

CE Certified 250 Micron Stainless Steel Mesh - High Durability & CE Approved

NewsJul.21,2025

-

Premium Slope Collapse Protection Mesh | Durable & Effective

NewsJul.20,2025

-

Safety Mesh for Windows – Durable Mosquito and Insect Protection Solutions

NewsJul.08,2025