Sep . 04, 2024 20:16 Back to list

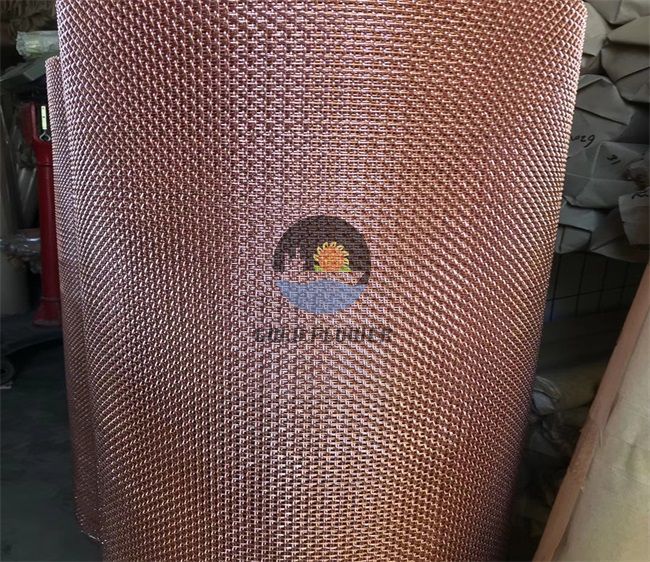

ODM Alloy Wire Mesh - High-Quality Custom Solutions

Understanding ODM Alloy Wire Mesh Features and Applications

ODM alloy wire mesh is a versatile and indispensable material in various industries due to its unique properties and functionality. This wire mesh is crafted from alloy materials, which exhibit enhanced strength, durability, and resistance to environmental factors compared to traditional wire mesh options. ODM, which stands for Original Design Manufacturer, indicates that the product can be custom-designed to meet specific requirements, ensuring that it suits diverse applications.

Composition and Properties

The primary characteristic of ODM alloy wire mesh is its composition. Typically made from stainless steel or other alloy materials, this type of wire mesh provides superior corrosion resistance, making it suitable for both indoor and outdoor applications. The alloys used in the production process can be tailored to meet specific performance metrics such as tensile strength, ductility, and thermal resistance.

For instance, stainless steel alloy wire mesh boasts high resistance to oxidation and tarnishing, making it ideal for environments exposed to moisture and chemicals. Furthermore, its fine yet robust weave structure creates a barrier that is effective for filtration purposes, while still allowing for adequate airflow and visibility. These attributes make ODM alloy wire mesh suitable for a variety of industrial, agricultural, and commercial uses.

Applications in Various Industries

1. Filtration and Separation Due to its precise and uniform mesh size, ODM alloy wire mesh is widely used in filtration applications. Industries such as water treatment, food and beverage, and pharmaceuticals benefit from its ability to separate solids from liquids effectively. The mesh can be designed to suit various filtration grades, ensuring compliance with industry standards.

odm alloy wire mesh

2. Construction and Architectural Uses In construction, ODM alloy wire mesh is employed as a reinforcement material in concrete structures. It enhances the strength of buildings while preventing cracking and structural failure. Moreover, its aesthetic appeal makes it a popular choice for architectural applications, such as decorative facades and railings.

3. Industrial Manufacturing In manufacturing, alloy wire mesh is utilized in sieving and sorting processes. Its robustness ensures that it can withstand heavy-duty applications, such as those found in mining and aggregate industries, where it helps in the efficient separation of materials.

4. Agriculture In the agricultural sector, this wire mesh plays a crucial role in creating protective enclosures for livestock and crops. Its strength and durability protect against pests and harsh weather conditions while allowing adequate sunlight and airflow.

5. Electronics and Aerospace The properties of ODM alloy wire mesh also make it suitable for use in the electronics and aerospace industries. It is used for EMI shielding and as part of components that require lightweight yet strong materials.

Conclusion

In summary, ODM alloy wire mesh is a highly functional material with a wide range of applications across various industries. Its customized design capabilities allow businesses to tailor it to their specific needs, enhancing operational efficiency and performance. With its exceptional properties, ODM alloy wire mesh continues to play a vital role in modern manufacturing and construction, effectively meeting the growing demands of today's industries. Whether for filtration, construction, or agriculture, the versatility of ODM alloy wire mesh is unmatched, making it a preferred choice for professionals across sectors.

share

-

High-Quality Screen Stone for Modern Stone Screen Walls Elegant Facade Solutions

NewsJun.10,2025

-

High Quality Wire Filter – Cheap Stainless Steel Filter Wire Mesh Cloth & Wire Mesh Filter Solutions

NewsJun.10,2025

-

5 Micron Water Filter Cartridge - Premium Sediment Filtration, Universal Fit

NewsJun.10,2025

-

High Quality CE-Certified Gabion Boxes with OEM Options

NewsJun.10,2025

-

20x20x2 Air Filter High-Efficiency Dust Filtration for Clean Air

NewsJun.10,2025

-

Decorative Metal Mesh for Radiator Covers Custom Durable Mesh Panels

NewsJun.10,2025