Nov . 15, 2024 04:53 Back to list

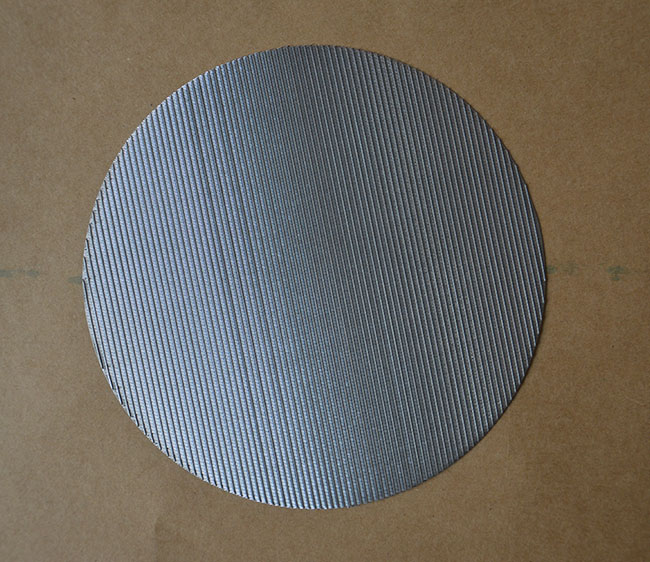

odm stainless steel wire mesh strainer

The Versatility and Utility of ODM Stainless Steel Wire Mesh Strainers

In the world of industrial and culinary equipment, the significance of strainers cannot be overstated. Among the various materials utilized for strainers, stainless steel has emerged as a preferred choice due to its durability, resistance to corrosion, and ease of maintenance. Specifically, ODM stainless steel wire mesh strainers have gained recognition for their robust design and versatile applications, making them indispensable in numerous settings, ranging from commercial kitchens to industrial processes.

Understanding Wire Mesh Strainers

At their core, wire mesh strainers serve a fundamental purpose to separate solids from liquids, ensuring that only the desired components of a mixture pass through. The construction of ODM stainless steel wire mesh strainers typically consists of a finely woven mesh, crafted from high-quality stainless steel. This combination results in excellent filtration capabilities, allowing for the efficient removal of particulate matter without compromising flow rates.

Why Choose Stainless Steel?

Stainless steel offers several advantages that enhance the performance and longevity of wire mesh strainers. First and foremost, the resistance to rust and corrosion inherent to stainless steel ensures that the strainer maintains its integrity in environments that involve exposure to moisture, chemicals, or extreme temperatures. This longevity makes stainless steel strainers a cost-effective investment, as they require less frequent replacement compared to those made from other materials.

Moreover, stainless steel is intrinsically hygienic. It does not harbor bacteria, making it an ideal choice for applications in food processing, pharmaceuticals, and water treatment. The ease of cleaning stainless steel surfaces further guarantees that contaminants are less likely to linger, thus adhering to necessary health and safety standards.

Applications of ODM Stainless Steel Wire Mesh Strainers

odm stainless steel wire mesh strainer

1. Culinary Uses In commercial kitchens, ODM stainless steel wire mesh strainers are commonly used for tasks like sifting flour, separating grains, and rinsing vegetables. Their fine mesh design helps achieve a smooth texture in sauces and soups while preventing unwanted pieces from entering the final product.

2. Industrial Filtration In industries such as oil and gas, chemical manufacturing, and wastewater treatment, stainless steel wire mesh strainers are crucial for protecting pumps and machinery from debris. They are often installed in pipelines to filter out solid particles, which could otherwise cause wear and tear on equipment and lead to costly repairs.

3. Aquaculture and Water Treatment In aquaculture, these strainers help separate fish feed from leftover feed and solids, ensuring a clean environment for aquatic life. Similarly, in water treatment facilities, they play a pivotal role in filtering out contaminants, contributing to cleaner, safer water for consumption.

Design Customization and Efficiency

One of the significant features of ODM stainless steel wire mesh strainers is the availability of custom designs. Depending on the specific requirements of the application, these strainers can be manufactured in various sizes, mesh openings, and configurations. This versatility enables industries to implement strainers that best suit their operational needs.

Additionally, the design of these strainers can facilitate easy installation and maintenance. Many models come equipped with quick-release mechanisms or are designed to fit standard pipe sizes, allowing for seamless integration into existing systems.

Conclusion

ODM stainless steel wire mesh strainers represent a convergence of functionality and durability across a multitude of applications. Their ability to efficiently filter liquids while withstanding harsh conditions makes them a reliable choice for both culinary and industrial environments. Investing in high-quality stainless steel strainers not only enhances operational efficiency but also contributes to maintaining safety and hygiene standards essential in today’s competitive landscape. Whether in the bustling environment of a restaurant kitchen or the demanding conditions of an industrial plant, these strainers are poised to deliver exceptional performance and longevity, proving their worth time and again.

share

-

Stainless Steel Wedge Wire Mesh: Durable, Precision Filtration

NewsAug.23,2025

-

CE Certified 250 Micron Stainless Steel Mesh for Precision Filtration

NewsAug.22,2025

-

CE Certified 250 Micron SS Mesh - Precision Filtration & Strength

NewsAug.21,2025

-

CE Certified Woven Wire Mesh Filters | Premium Filtration Solutions

NewsAug.19,2025

-

High-Performance Particle Filters: Optimal Mediums & Applications

NewsAug.18,2025

-

Competitive Screen Mesh Price | 1/4", 1/8", 1/2" Wire Mesh Screens

NewsAug.17,2025