Dec . 04, 2024 08:01 Back to list

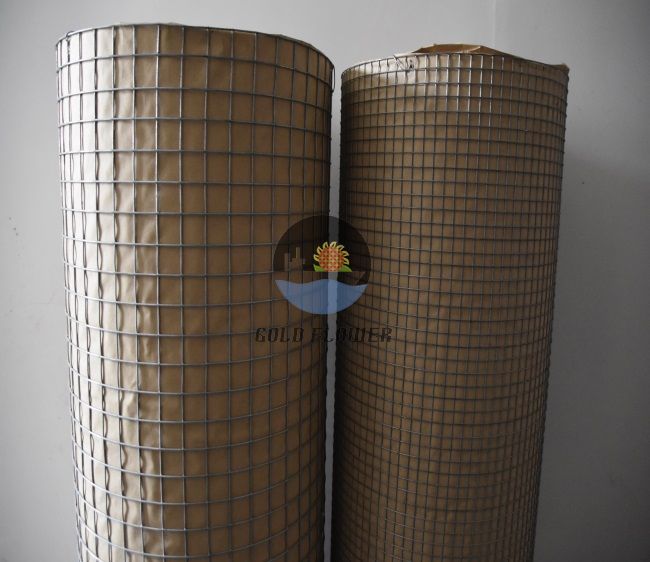

OEM High-Quality Stainless Steel Wire Mesh Screen for Versatile Applications

The Versatility and Applications of OEM Stainless Steel Wire Screen Mesh

Stainless steel wire screen mesh has become an essential component in various industries due to its remarkable properties, versatility, and durability. When it comes to OEM (Original Equipment Manufacturer) solutions, stainless steel wire screen mesh offers customized options that cater to the specific needs of different applications. This article explores the properties, advantages, and various applications of stainless steel wire screen mesh, illuminating its significance in today's industrial landscape.

Understanding Stainless Steel Wire Screen Mesh

Stainless steel wire screen mesh is woven from high-quality stainless steel wires, known for their excellent resistance to corrosion, heat, and wear. The use of stainless steel, particularly grades like 304 and 316, ensures that the mesh remains functional and visually appealing even in harsh environments. The weaving process can vary, leading to different mesh openings that provide various levels of filtration and support.

The custom nature of OEM stainless steel wire screen mesh allows manufacturers to specify dimensions, weave patterns, and openings to satisfy individual project requirements. This flexibility serves multiple industries, from food processing to petrochemicals, making it a favored choice among engineers and designers.

Properties of Stainless Steel Wire Screen Mesh

1. Corrosion Resistance One of the standout features of stainless steel is its impeccable resistance to rust and corrosion. This property makes it the ideal candidate for applications where exposure to moisture or chemicals is a concern.

2. High Strength-to-Weight Ratio Stainless steel wire screen mesh offers excellent strength while remaining lightweight. This characteristic allows for easy handling, installation, and transport.

3. Durability With resistance to abrasion and impact, stainless steel wire screen mesh maintains its integrity and performance quality over time, leading to reduced maintenance costs and extended service life.

4. Temperature Resistance The alloy composition of stainless steel provides superior performance under extreme temperatures, making it suitable for various high-heat applications.

Advantages of Using OEM Stainless Steel Wire Screen Mesh

When partnering with an OEM manufacturer for stainless steel wire screen mesh, businesses can benefit from several key advantages

oem stainless steel wire screen mesh

2. Quality Assurance Reputable OEM suppliers adhere to strict quality control measures, guaranteeing consistency, reliability, and safety in the products they deliver.

3. Cost-Effectiveness While stainless steel may have a higher upfront cost compared to other materials, its durability and longevity can lead to significant savings over time in maintenance, replacement, and operational costs.

4. Aesthetically Pleasing The sleek look of stainless steel enhances the overall appearance of applications, making it an excellent choice for visible components in architectural and decorative designs.

Applications of Stainless Steel Wire Screen Mesh

The applications of OEM stainless steel wire screen mesh are diverse, spanning multiple sectors

1. Filtration In water treatment and food processing industries, stainless steel wire mesh is used for filtering liquids and solids, ensuring purity and compliance with health standards.

2. Construction and Architecture Architects and builders leverage stainless steel mesh for safety barriers, facades, and decorative elements, combining functionality with aesthetic appeal.

3. Mining and Quarrying Heavy-duty stainless steel mesh is vital in mining for sieving and sizing materials, handling abrasive materials without deteriorating over time.

4. Automobile Manufacturing In the automotive sector, stainless steel wire mesh components are used for air filtration, exhaust systems, and structural reinforcements, playing a crucial role in vehicle performance.

5. Electronics and Telecommunications Stainless steel wire screen mesh is employed in EMI shielding and for creating protective enclosures for sensitive electronic components.

Conclusion

The growing demand for OEM stainless steel wire screen mesh signifies its critical role across various industries. With properties like corrosion resistance, durability, and customization, it provides practical solutions tailored to meet unique industrial challenges. As technology continues to advance and industries evolve, the importance of high-quality, tailored stainless steel wire screen mesh will undoubtedly grow, cementing its place as a cornerstone material in modern manufacturing and design.

share

-

CE Certified 250 Micron Stainless Steel Mesh | Precision & Durability

NewsAug.27,2025

-

CE Certified 250 Micron Stainless Steel Mesh for Precision & Durability

NewsAug.26,2025

-

CE Certified 250 Micron Stainless Steel Mesh for Precision & Durability

NewsAug.25,2025

-

Premium CE Certified Metal Fine Mesh for Precision & Safety

NewsAug.24,2025

-

Stainless Steel Wedge Wire Mesh: Durable, Precision Filtration

NewsAug.23,2025

-

CE Certified 250 Micron Stainless Steel Mesh for Precision Filtration

NewsAug.22,2025