Sep . 29, 2024 06:36 Back to list

High-Quality OEM Ultra-Fine Wire Mesh for Precision Filtration Solutions

Exploring the Advantages of OEM Ultra Fine Wire Mesh

In today's highly competitive manufacturing landscape, the need for precision and quality has never been greater. This is particularly true in industries such as pharmaceuticals, electronics, and food processing, where the minutest details can significantly impact product performance and safety. One innovative solution that has garnered attention in various sectors is OEM (Original Equipment Manufacturer) ultra fine wire mesh. This article delves into the characteristics, applications, and benefits of this remarkable material.

What is Ultra Fine Wire Mesh?

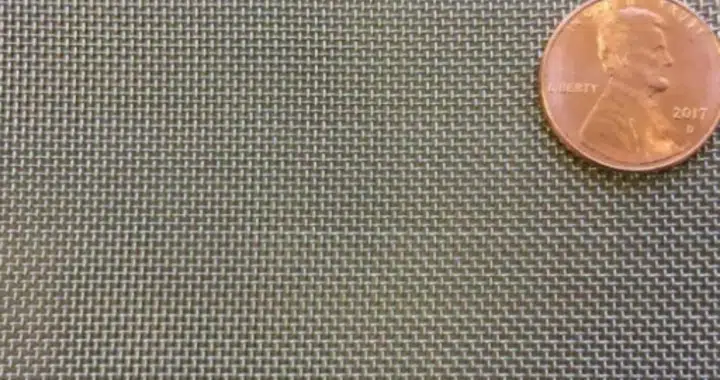

Ultra fine wire mesh is a type of woven mesh made from extremely thin wires. The mesh typically features openings that range from a few microns to several hundred microns, allowing for the filtration, separation, and sorting of particles to very fine levels. The increased surface area and intricate weaving patterns provide the ability to effectively filter air, liquids, and even solids. This level of precision makes ultra fine wire mesh an invaluable asset in many manufacturing processes.

Key Characteristics

1. High Precision Filtration One of the defining features of ultra fine wire mesh is its capacity for high-precision filtration. Its small pore size enables the filtration of the tiniest contaminants, which is crucial in industries such as pharmaceuticals, where even the smallest impurities can jeopardize the integrity of a drug product.

2. Durability and Strength Despite its fine mesh structure, ultra fine wire mesh is often constructed from robust materials such as stainless steel, brass, and nylon. This combination of fine wires with durable materials ensures that the mesh can withstand rigorous operational conditions and is resistant to wear and corrosion.

3. Customizability OEM ultra fine wire mesh can be tailored to meet specific product requirements. Manufacturers can adjust the wire diameter, mesh opening size, and overall dimensions to fit unique applications, making it a versatile option for diverse industries.

4. Chemical Resistance Many applications require materials that can withstand harsh chemicals and extreme temperatures. Ultra fine wire mesh products are available in various materials that maintain their integrity and performance in these challenging environments.

Applications of OEM Ultra Fine Wire Mesh

The applications of OEM ultra fine wire mesh are extensive, spanning several key industries

1. Pharmaceuticals In the pharmaceutical industry, ultra fine wire mesh is essential for filtering active ingredients and ensuring that the products are free from contaminants. It is commonly used in processes such as formulation, drug manufacturing, and sterile packaging.

oem ultra fine wire mesh

2. Food and Beverage The food industry relies heavily on ultra fine wire mesh for separating solids from liquids, ensuring that food products are safe and free of foreign particles. It is also used in brewing and beverage filtration, enhancing product purity and quality.

3. Electronics In the electronics sector, ultra fine wire mesh is utilized in screen printing circuits, filtering materials in manufacturing, and as a protective barrier against environmental contamination.

4. Aerospace and Automotive These industries use ultra fine wire mesh for applications like filtration systems, ensuring that oil, fuel, and air remain free from particulates, which could potentially harm engine efficiency and safety.

Benefits of Utilizing OEM Ultra Fine Wire Mesh

The integration of OEM ultra fine wire mesh into manufacturing processes brings about numerous benefits

1. Enhanced Product Quality By ensuring that the final products are free from contaminants, manufacturers can enhance their product quality and reliability.

2. Increased Efficiency Ultra fine wire mesh filtration systems can operate continuously, reducing downtime and maintenance costs associated with traditional filtering methods.

3. Cost-effective Production Although the initial investment might seem significant, the long-term benefits of improved efficiency, product quality, and reduced material waste can result in substantial cost savings.

4. Regulatory Compliance Many industries have stringent regulations regarding product purity and safety. Incorporating ultra fine wire mesh helps manufacturers meet these standards, ensuring compliance and avoiding potential legal issues.

Conclusion

In conclusion, OEM ultra fine wire mesh represents a vital innovation in modern manufacturing. Its unique properties, including high precision filtration, durability, and customizability, make it a versatile tool across various industries. By leveraging this technology, manufacturers can enhance product quality, improve efficiency, and navigate the complex regulatory landscapes of their respective fields. As industries continue to evolve, the importance of high-quality filtration solutions like ultra fine wire mesh is bound to grow, leading to more advanced, precise, and safe products for consumers around the globe.

share

-

Premium Stainless Steel Netting Mesh Discount & ODM Stainless Steel Wire Mesh Solutions

NewsJun.24,2025

-

High-Quality Screen Stone for Modern Stone Screen Walls Elegant Facade Solutions

NewsJun.10,2025

-

High Quality Wire Filter – Cheap Stainless Steel Filter Wire Mesh Cloth & Wire Mesh Filter Solutions

NewsJun.10,2025

-

5 Micron Water Filter Cartridge - Premium Sediment Filtration, Universal Fit

NewsJun.10,2025

-

High Quality CE-Certified Gabion Boxes with OEM Options

NewsJun.10,2025

-

20x20x2 Air Filter High-Efficiency Dust Filtration for Clean Air

NewsJun.10,2025