Jan . 06, 2025 11:19 Back to list

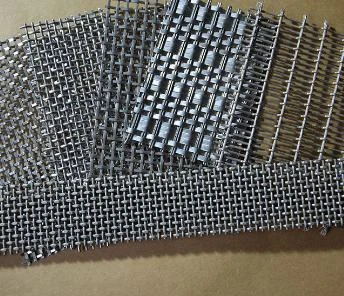

wire net

Wire net, or wire mesh, plays an indispensable role across a myriad of industries due to its versatile applications and unparalleled adaptability. Its unique composition makes it a favored material for a range of tasks, from domestic installations to industrial undertakings. As someone who has extensively worked with wire net across various sectors, I've acquired insights that underscore its value, functionality, and reliability.

One critical aspect that sets wire net apart is its customizable nature. This characteristic allows it to be tailored in terms of material, weave, aperture size, and tensile strength, meeting specific requirements for different applications. For example, in construction and building, particularly in reinforced concrete, wire net provides the necessary structural support, ensuring stability and longevity. It effectively distributes weight and adds flexibility, preventing undue stress and providing resilience against environmental conditions.

The agricultural sector benefits from wire net in several ways. Its robust nature secures perimeters, safeguarding crops and keeping livestock contained while allowing adequate airflow. The durability of galvanized or stainless-steel mesh resists rust and corrosion, which is vital for outdoor use where exposure to the elements is frequent.

Moreover, wire net is extensively used for security purposes due to its formidable design and endurance. High-security installations, such as prisons, can integrate wire net into their infrastructure, ensuring that barriers remain impenetrable to vandalism or unauthorized entry. The fine mesh size deters climbing and cutting, adding an extra layer of security that is essential in such high-stakes environments.

The artistic and creative sectors are not left behind either. Wire net can serve as a medium for sculptors and artists, accommodating a spectrum of artistic visions due to its malleability and ability to hold shape. This provides creators with the freedom to experiment and conceptualize large-scale pieces that maintain structural integrity while pushing the boundaries of design.

wire net

Despite its widespread use, the key to maximizing the benefits of wire net lies in its careful selection and application. Expertise in choosing the right type of wire mesh is crucial. Each variant offers distinct properties welded wire for rigidity, woven wire for flexibility, or expanded mesh for lightness. Understanding these differences is essential for professionals who aim to employ wire net efficiently.

Trustworthiness and safety remain paramount in industries utilizing wire netting. Manufacturers are increasingly subject to stringent quality control measures and compliance with international standards. This ensures consistency in performance and reliability, which end-users can depend on. Occupational health and safety policies in industrial applications necessitate adherence to these quality benchmarks to protect workers and guarantee safe operation.

Furthermore, the forward-thinking sector is gravitating towards sustainability, and wire net is proving to be an ally in this cause. Its recyclability ecoviume means that after serving its purpose, the material can be reprocessed, aligning with global environmental goals while providing cost-effective solutions for businesses.

In conclusion, wire net's adaptability, robustness, and sustainability make it an invaluable material. Its incorporation across varied domains highlights its essential role in enhancing product efficacy, ensuring safety, and supporting innovative solutions. For those seeking materials that promise consistent performance backed by expertise, wire net remains a top contender, bridging the gap between tradition and innovation with admirable reliability.

share

-

CE Certification Metal Fine Mesh for Safety & Durability

NewsJul.24,2025

-

High-Efficiency Particle Filter for Superior Air Purification

NewsJul.23,2025

-

CE Certification 250 Micron Stainless Steel Mesh for Industrial Use

NewsJul.22,2025

-

CE Certified 250 Micron Stain Steel Mesh - Durable & Safe

NewsJul.21,2025

-

CE Certified 250 Micron Stainless Steel Mesh - High Durability & CE Approved

NewsJul.21,2025

-

Premium Slope Collapse Protection Mesh | Durable & Effective

NewsJul.20,2025