Gas Filtration SS Wire Mesh

Gas filtration SS wire mesh is selected for their wear-resisting, heat-resisting, acid-resisting and corrosion resisting characteristics.

Gas filtration SS wire mesh is used in general industrial use applications, like heavy duty particle separation, water filtration and food processing. Such as:mining, quarrying, security, used in instances where air flow is needed. Other of these can be used in scientific applications. Non-industrial users also find some of these specifications suitable for various decorative and artistic applications.

The weaving is determined according to our customers specific requirements, such as the material, the wire diameter, the size of the mesh , width and length.

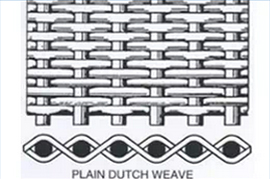

Plain weave:

Each warp wire crosses alternately above and below each weft wire. Warp and weft wires generally have the same diameter.

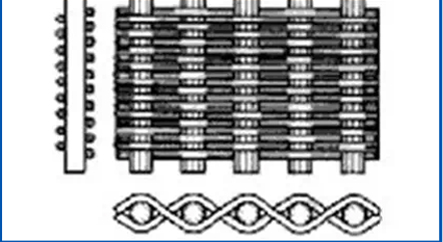

Twill Weave:

The wires of the weft and the warp intercross two above and two below, inverting the intersections of the warp wire at an established distance and obtaining a rigid, stable and robust type of wire mesh fabric.

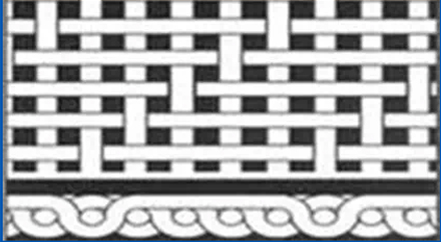

Dutch Twilled Weaving:

The wires of the weft and the warp intercross two above with a larger weft wire than the warp.

Feature of Gas filtration wire mesh

· Corrosion resistance.

· Anti-acid and alkali resistance

· Anti-high temperture.

· Good filter performance.

· Long using life

| ÐÐ¾Ð¼ÐµÑ ÑеÑки | ÐоминалÑнÑй ÑÐ°Ð·Ð¼ÐµÑ ÑÑоÑÐ¾Ð½Ñ ÑÑейки в ÑвеÑÑ, мм | ÐоминалÑнÑй диамеÑÑ Ð¿Ñоволоки, мм |

| 04 | 0,40 | 0,20; 0,25 |

| 045 | 0,45 | 0,20; 0,25 |

| 05 | 0,50 | 0,20; 0,25; 0,30 |

| 055 | 0,55 | 0,22; 0,28 |

| 063 | 0,63 | 0,25; 0,32 |

| 07 | 0,70 | 0,22; 0,28; 0,32 |

| 08 | 0,80 | 0,25; 0,32 |

| 09 | 0,90 | 0,22; 0,36 |

| 1 | 1,00 | 0,25; 0,32; 0,40 |

| 1,1 | 1,10 | 0,28; 0,36 |

| 1,2 | 1,20 | 0,32; 0,40 |

| 1,4 | 1,40 | 0,36; 0,45; 0,65 |

| 1,6 | 1,60 | 0,32; 0,40 |

| 1,8 | 1,80 | 0,45; 0,05; 0,70 |

| 2 | 2,00 | 0,40; 0,50; 0,60; 1,00; 1,20 |

| 2,5 | 2,50 | 0,40; 0,50; 0,60 |

| 2,8 | 2,80 | 0,45; 0,90 |

| 3,2 | 3,20 | 0,50; 0,80; 1,20 |

| 3,5 | 3,50 | 0,70; 0,90; 1,00 |

| 4 | 4,00 | 0,60; 1,00; 1,20 |

| 4,5 | 4,50 | 0,70; 0,90; 1,80 |

| 5 | 5,00 | 0,70;1,20; 1,60; 2,00 |

| 6 | 6,00 | 0,70; 1,20; 2,00 |

| 7 | 7,00 | 0,70; 1,20; 1,80 |

| 8 | 8,00 | 0,70; 1,20; |

| 9 | 9,00 | 1,60; 2,00 1,00; 2,00; |

| 10 | 10,00 | 2,20 |

| 12 | 12,00 | 1,00; 2,00; 1,00; 1,20; |

| 14 | 14,00 | 2,00; 1,00; 1,40; 2,00 |

| 16 | 16,00 | 1,60; 2,50 |

| 18 | 18,00 | 1,80; 2,50 1,60; 2,00; |

| 20 | 20,00 | 2,50 |

-

Plain dutch weave

-

Twilled dutch weave

-

Reverse dutch waeve 1

-

Reverse dutch weave 2

-

Five-heddle weave

-

Material Production

-

Diameter Inspect

-

Tension Test

-

Material Check

-

Material Check

-

Trimming Edge

-

Length and Width Inspect

-

Hole Size Test

-

Mesh Inspect

-

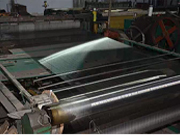

Weaving

-

Intension Test

-

Diameter Inspect

-

Thickness Inspect

-

Role size Inspect

-

Mesh Test

-

Length and Width Check

-

Trimming Edge

-

Mesh Inspect

With the most perfect way to protect your cargo security

-

1

Cardboard Tube

-

2

Thick Paper Board

-

3

Thick Plastic Cloth

-

4

Perfect Wooden Case

-

5

Thick Plastic Bubble Film

-

6

Excellent Cover

-

7

Steel Strap Fix

-

8

Package Check

-

9

Container Transport