nov . 09, 2024 20:03 Back to list

High Strength Woven Wire Mesh for Durable Applications in China

High Tensile Woven Wire Mesh A Comprehensive Overview

High tensile woven wire mesh is a vital material with diverse applications across various industries, such as construction, agriculture, mining, and manufacturing. Its unique properties, including strength, durability, and flexibility, make it an ideal choice for a wide range of uses. This article provides an overview of high tensile woven wire mesh, focusing on its characteristics, advantages, manufacturing process, and common applications.

Characteristics of High Tensile Woven Wire Mesh

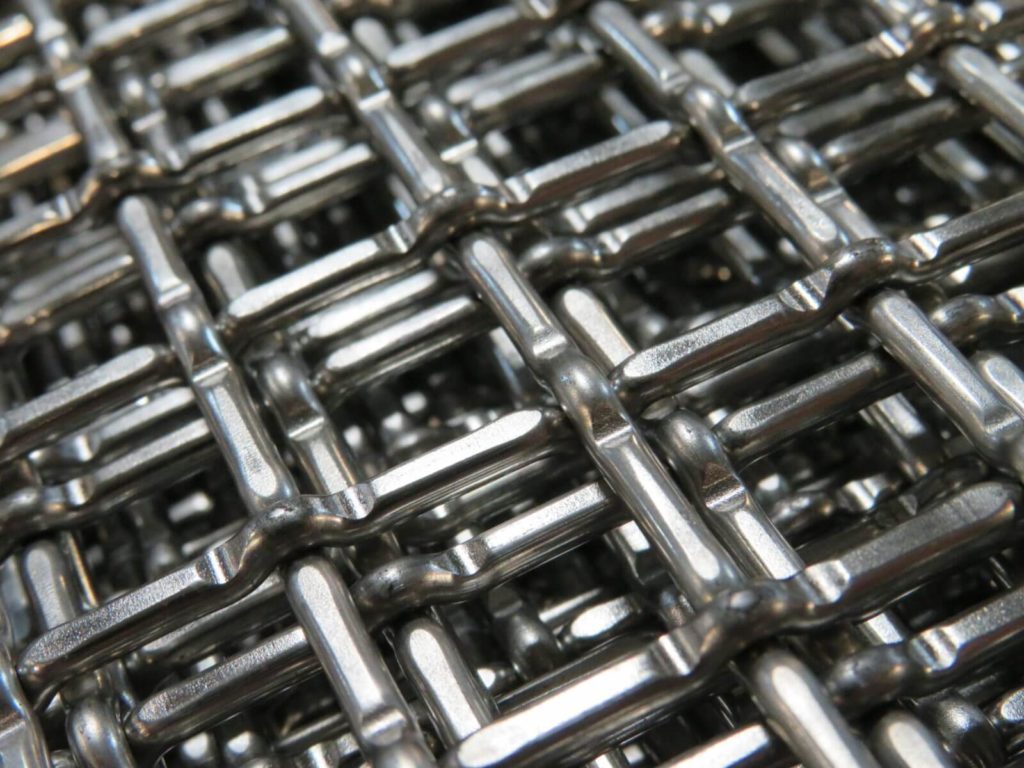

High tensile woven wire mesh is characterized by its robust structure, which is created by weaving high-strength wire at specific intervals. The mesh is typically made from materials such as stainless steel, galvanized steel, or other high-carbon steel, which contribute to its excellent tensile strength and resistance to corrosion. The wire thickness and mesh opening size can vary, allowing for customization based on specific requirements.

One of the most notable features of high tensile woven wire mesh is its ability to withstand significant loads and stresses, making it suitable for heavy-duty applications. Additionally, the woven design provides a level of flexibility, enabling the mesh to maintain its shape without compromising strength, even under challenging conditions.

Advantages of High Tensile Woven Wire Mesh

1. Strength and Durability The primary advantage of high tensile woven wire mesh is its exceptional strength. The use of high-tensile wires means that the mesh can support heavy loads without deformation, making it ideal for structural applications. Its durability ensures a long service life, which translates to cost savings over time.

2. Corrosion Resistance When made from stainless steel or galvanized materials, high tensile woven wire mesh exhibits excellent resistance to rust and corrosion. This attribute is crucial for outdoor applications or in industries where exposure to harsh chemicals or environmental conditions is a concern.

3. Versatility High tensile woven wire mesh can be used in various applications, including fencing, filtration, and as support in construction projects. This versatility allows it to serve multiple functions across different sectors.

4. Ease of Installation Due to its lightweight nature and flexible design, high tensile woven wire mesh is relatively easy to install. This ease can reduce labor costs and installation time.

5. Customizability Manufacturers can tailor high tensile woven wire mesh to meet specific project needs. Customers can choose wire thickness, mesh size, and material type, ensuring that the final product fits their requirements precisely.

china high tensile woven wire mesh

Manufacturing Process

The production of high tensile woven wire mesh begins with the selection of high-quality wire. After securing the appropriate material—whether stainless steel, galvanized steel, or coated wire—the wire is drawn to the desired thickness. The wire is then woven using advanced machinery that aligns and interlaces the strands at specific intervals to create a sturdy mesh structure.

Quality control is a critical part of the manufacturing process. Each batch of wire mesh undergoes rigorous testing to ensure that it meets strength and durability standards. Additionally, various surface treatments can be applied to enhance corrosion resistance and improve the mesh's overall longevity.

Common Applications

High tensile woven wire mesh is employed in a variety of applications across multiple industries

- Construction It is widely used in concrete reinforcement, with mesh sheets being integrated into structures to improve tensile strength.

- Fencing The mesh is commonly used for agricultural and industrial fencing, providing security and delineating property boundaries.

- Mining In mining operations, high tensile woven wire mesh is employed for screening and separating materials, ensuring optimal efficiency in extraction processes.

- Filtration The mesh's fine openings make it suitable for filtering applications in water treatment, oil and gas industries, and food processing.

- Architectural Applications Designers also leverage woven wire mesh for aesthetic purposes, creating unique facades, ceilings, and interior features.

In conclusion, high tensile woven wire mesh stands out as a robust and versatile material that is crucial for various sectors. Its strength, durability, and adaptability make it a preferred choice for many applications, underscoring its importance in modern industry. As technology advances, the production and applications of high tensile woven wire mesh are likely to expand even further, paving the way for innovative uses in the future.

share

-

CE Certified 250 Micron Stainless Steel Mesh Filter

NewsAug.04,2025

-

Premium Twill Weave Mesh for Industrial Filtration & Strength

NewsAug.03,2025

-

CE Certified 250 Micron Stainless Steel Mesh - Durable Filter

NewsAug.02,2025

-

CE Certified 250 Micron Stainless Steel Filter Mesh | Premium

NewsJul.31,2025

-

CE Certified 250 Micron Stainless Steel Mesh | Premium Filter

NewsJul.31,2025

-

CE Certification Buy Wire Mesh Fence for High Security and Durability

NewsJul.30,2025