aug . 17, 2024 13:57 Back to list

Custom Metal Mesh Fabric Solutions for OEM Applications and Industrial Needs

Exploring the Versatility of OEM Metal Mesh Fabric

In the modern landscape of manufacturing and design, the use of OEM (Original Equipment Manufacturer) metal mesh fabric has emerged as a significant innovation. This material, characterized by its strength, durability, and aesthetic appeal, caters to a wide array of industries and applications. From architectural design to automotive components, OEM metal mesh fabric is forging a new path in material science.

Understanding OEM Metal Mesh Fabric

OEM metal mesh fabric refers to custom-designed mesh products that are produced by manufacturers to meet specific client needs. The fabric is typically made from stainless steel, aluminum, or other alloys, which provide not only structural integrity but also resistance to corrosion and wear. The mesh is engineered into various patterns, sizes, and thicknesses, enabling versatility in application. Manufacturers often use advanced fabrication techniques to produce meshes that can be tailored to the exact specifications of clients, ensuring that every product delivered aligns with their requirements.

Applications Across Industries

One of the primary industries benefiting from OEM metal mesh fabric is architecture. The aesthetic appeal of metal mesh is utilized in facades, sunshades, and dividers, allowing natural light to filter through while providing privacy and ventilation. Designers appreciate the mesh's ability to create dynamic visual impacts, enhancing the overall look of a building while maintaining functionality.

In the automotive sector, OEM metal mesh fabric is employed for its lightweight properties and heat resistance, making it ideal for components such as filters, grilles, and protective shields. The automotive industry values this material for its ability to withstand harsh environmental conditions while providing necessary airflow and protection.

Similarly, the aerospace industry utilizes metal mesh fabrics in various components due to their strength-to-weight ratio. Parts like screens and separators made from these materials contribute to the overall performance and safety of aircraft. OEM metal mesh fabric’s capacity to endure extreme conditions makes it a preferred choice in this highly regulated field.

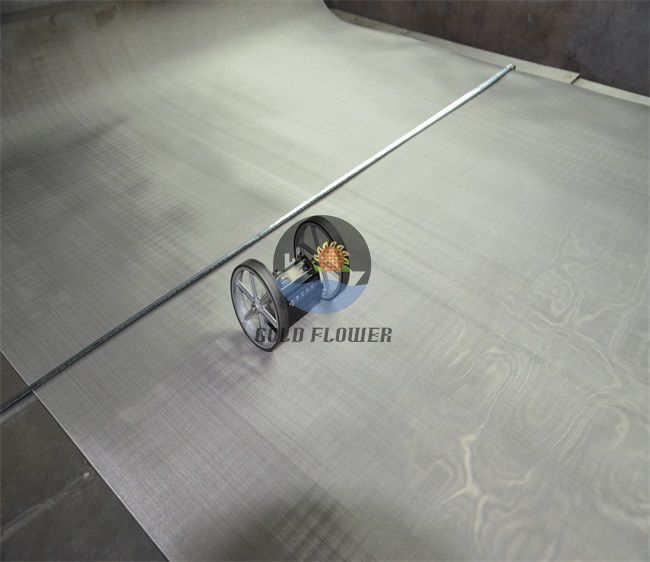

oem metal mesh fabric

Benefits of OEM Metal Mesh Fabric

One of the most significant advantages of OEM metal mesh fabric is its customizable nature. By working with manufacturers, businesses can specify the precise characteristics they need, whether it be specific dimensions, wire thickness, or mesh openings. This tailored approach not only enhances the functionality of the end product but also ensures that it meets industry standards and regulations.

Durability is another compelling benefit. Unlike traditional fabrics that may wear out or degrade over time, metal mesh fabrics are designed to last. They resist tearing, fraying, and corrosion, making them ideal for both indoor and outdoor applications. This long lifespan translates into cost savings for businesses, as they do not need to frequently replace their materials.

Sustainability Considerations

With a growing emphasis on sustainability in manufacturing, OEM metal mesh fabric presents an environmentally friendly option. Metals used can often be recycled, reducing waste and minimizing environmental impact. Furthermore, the longevity of metal mesh products contributes to sustainability, as durable materials lead to less frequent replacements and lower overall consumption.

Conclusion

OEM metal mesh fabric stands out as an extraordinary material that seamlessly blends functionality with aesthetic appeal. Its versatility in various industries highlights the demand for innovative solutions in manufacturing. By leveraging the benefits of customization, durability, and sustainability, businesses can enhance their products and meet the ever-evolving needs of the market. As applications continue to expand, the role of OEM metal mesh fabric in shaping the future of design and engineering remains paramount.

share

-

Premium Stainless Steel Netting Mesh Discount & ODM Stainless Steel Wire Mesh Solutions

NewsJun.24,2025

-

High-Quality Screen Stone for Modern Stone Screen Walls Elegant Facade Solutions

NewsJun.10,2025

-

High Quality Wire Filter – Cheap Stainless Steel Filter Wire Mesh Cloth & Wire Mesh Filter Solutions

NewsJun.10,2025

-

5 Micron Water Filter Cartridge - Premium Sediment Filtration, Universal Fit

NewsJun.10,2025

-

High Quality CE-Certified Gabion Boxes with OEM Options

NewsJun.10,2025

-

20x20x2 Air Filter High-Efficiency Dust Filtration for Clean Air

NewsJun.10,2025