nov . 06, 2024 08:17 Back to list

OEM 304 Stainless Steel Wire Mesh Screens for Various Applications and Industries

The Versatility and Applications of OEM 304 Stainless Steel Mesh Screens

Stainless steel mesh screens are an essential component in various industries, offering durability, corrosion resistance, and versatility. Among the different grades available, OEM 304 stainless steel mesh screens stand out due to their ideal balance of strength and flexibility. This article explores the characteristics, benefits, and applications of OEM 304 stainless steel mesh screens, showcasing why they are the preferred choice for many manufacturers and industries.

Understanding 304 Stainless Steel

304 stainless steel is one of the most widely used stainless steel grades, primarily due to its excellent corrosion resistance and high strength. This particular grade contains a composition of approximately 18% chromium and 8% nickel, making it resistant to rust and oxidation. Its non-magnetic properties and ability to withstand high temperatures up to 870°C (1,600°F) also contribute to its popularity across various sectors.

Unique Features of OEM 304 Stainless Steel Mesh Screens

1. Corrosion Resistance The high chromium content in 304 stainless steel imparts excellent resistance to a wide range of corrosive environments. This makes it suitable for applications in food processing, chemical manufacturing, and marine environments, where exposure to harsh chemicals and moisture is common.

2. Strength and Durability OEM 304 stainless steel mesh screens are engineered to withstand significant stress and pressure. Their durability ensures long-lasting performance, reducing the need for frequent replacements and maintenance.

3. Versatility The mesh structure can be customized to different wire diameters and opening sizes, catering to specific filtration and separation requirements. Whether a fine mesh is needed for filtering particulates or a coarse mesh for structural applications, OEM 304 stainless steel mesh screens can be tailored accordingly.

4. Ease of Cleaning Unlike other materials, stainless steel is easy to clean and maintain. This is particularly important in industries like food and pharmaceuticals, where hygiene is paramount. The smooth surface of 304 stainless steel prevents the accumulation of contaminants, making it an ideal choice for various applications.

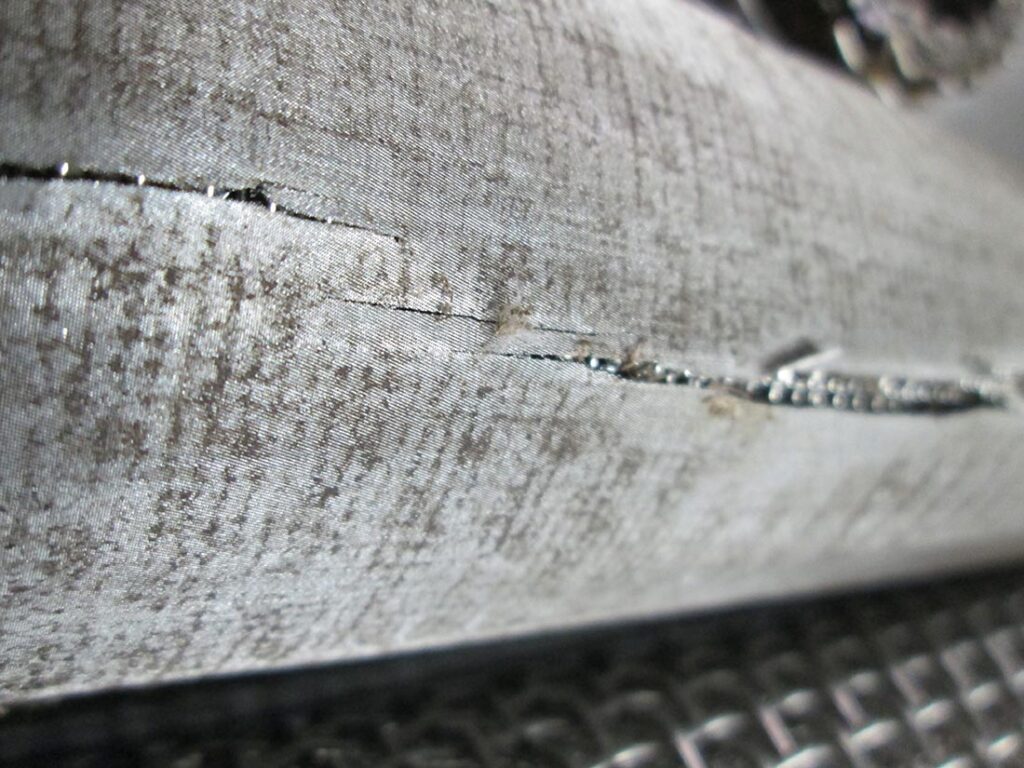

oem 304 stainless steel mesh screen

Applications of OEM 304 Stainless Steel Mesh Screens

1. Filtration and Separation One of the most common uses for 304 stainless steel mesh screens is in filtration systems. They are used in water treatment plants, food and beverage processing, and various industrial processes to separate solids from liquids. The ability to customize mesh size allows for precise filtration, ensuring the removal of unwanted materials while retaining the desired products.

2. Architectural and Design Elements Beyond industrial uses, 304 stainless steel mesh screens are also popular in architecture and design. They can be used to create elegant facades, partitions, and ceilings, adding an aesthetic appeal while offering durability. The modern look of stainless steel complements various design styles, making it a popular choice among architects and designers.

3. Automotive and Aerospace Industries In these high-performance sectors, the lightweight and strong nature of 304 stainless steel mesh screens makes them invaluable. They are used in exhaust systems, filtration devices, and as protective barriers, contributing to the efficiency and safety of vehicles and aircraft.

4. HVAC Systems OEM 304 stainless steel mesh screens play a vital role in heating, ventilation, and air conditioning systems. They are used in filters to maintain clean air quality by trapping dust, debris, and other airborne particles. Their durability ensures they can withstand the rigors of continuous airflow without degrading.

5. Medical Equipment The medical field demands high hygiene standards, and 304 stainless steel mesh screens fit the bill perfectly. They are utilized in various medical devices and equipment, ensuring that contamination is minimized while maintaining structural integrity.

Conclusion

OEM 304 stainless steel mesh screens are a prime example of how advanced materials can meet diverse needs across multiple industries. Their strength, versatility, and resistance to corrosion make them an indispensable tool in applications ranging from filtration to architectural design. As industries continue to evolve, the demand for reliable, high-performance materials like 304 stainless steel will only grow, solidifying its position as a preferred choice in various sectors.

share

-

Durable 1.8m Chain Link Fence for Secure Perimeter Protection

NewsJun.06,2025

-

Custom Air Filters - Premium Quality & Tailored Fit for Optimal Efficiency

NewsJun.06,2025

-

Premium Aluminium Mosquito Screens Durable & Bug-Free

NewsJun.06,2025

-

16x18x1 Air Filter - High Efficiency for HVAC & Compressors

NewsJun.06,2025

-

Best Chain Link Fence Heights 8ft High Security & Low Cost

NewsJun.06,2025

-

Durable Pleated Insect Screen Easy Fit & Insect Protection

NewsJun.05,2025