okt . 17, 2024 01:54 Back to list

Custom Steel Mesh Solutions for OEM Applications and Industrial Needs

The Advancements and Applications of OEM Mesh Steel

In the modern world of manufacturing, the significance of materials that combine strength, versatility, and lightweight properties cannot be overstated. One such material that embodies these qualities is mesh steel, increasingly produced by Original Equipment Manufacturers (OEMs). This article delves into the characteristics, applications, benefits, and future of OEM mesh steel.

What is OEM Mesh Steel?

OEM mesh steel refers to steel products that are crafted into mesh forms through various manufacturing techniques. This mesh can consist of different interlocking patterns that enhance its structural integrity, making it suitable for a myriad of applications. OEMs leverage their manufacturing prowess to produce steel mesh tailored for specific requirements, ensuring that industries can utilize materials that meet stringent standards and specifications.

Characteristics of OEM Mesh Steel

1. Strength and Durability Mesh steel is renowned for its high tensile strength, allowing it to withstand significant stress and load. This characteristic makes it ideal for applications in construction and heavy industry.

2. Lightweight Design Despite its strength, mesh steel is relatively lightweight compared to solid steel structures. This quality facilitates easier handling and installation, reducing labor costs and time in various projects.

3. Versatility The adaptable nature of OEM mesh steel means it can be produced in various sizes, shapes, and designs. This versatility ensures that it can meet specific needs, whether for architectural designs, security solutions, or industrial applications.

4. Corrosion Resistance Many manufacturers enhance mesh steel with protective coatings or alloying elements that ensure longevity and resistance to environmental factors. This is crucial for applications exposed to harsh conditions.

Applications of OEM Mesh Steel

1. Construction and Building One of the primary applications of OEM mesh steel is in the construction industry. It is widely used for reinforcing concrete structures, such as foundations, walls, and slabs, providing them with additional strength and stability.

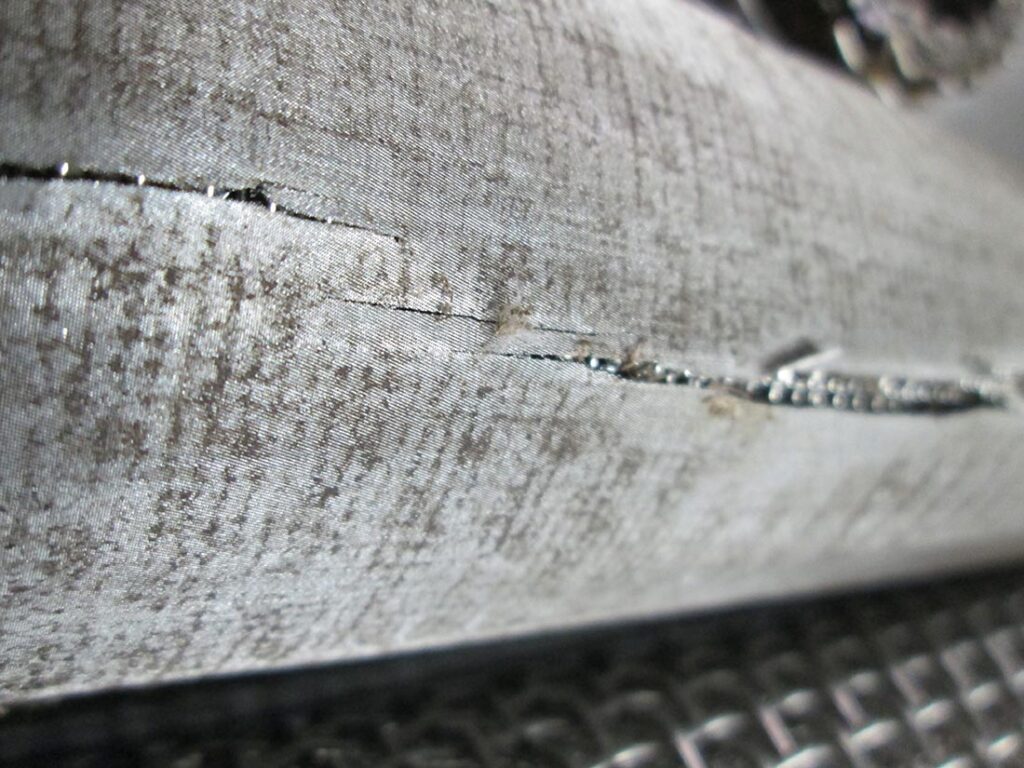

oem mesh steel

2. Security Fencing OEM mesh steel is also commonly used in security fencing. The robust interlocking design makes it difficult to penetrate, making it an effective solution for securing properties, facilities, and public spaces.

3. Industrial Flooring Mesh steel is employed in the creation of industrial flooring systems. Its strength allows it to support heavy loads while providing good ventilation, which is essential in industrial environments.

4. Automotive Industry In the automotive sector, OEM mesh steel is vital for manufacturing components like grills, bumpers, and safety barriers. The lightweight yet strong nature of the material contributes to vehicle efficiency and safety.

5. Agricultural Uses The agricultural sector also benefits from the use of mesh steel in wire fencing, livestock enclosures, and equipment storage, demonstrating the material's versatility beyond conventional applications.

Benefits of OEM Mesh Steel

The benefits of integrating OEM mesh steel into various projects are manifold. By sourcing mesh steel from OEMs, businesses gain access to high-quality, customized materials tailored to their specific needs. This results in enhanced performance and longevity of structures and products.

Moreover, using OEM mesh steel can lead to cost savings in terms of reduced material waste and easier installation processes. The adaptability of the design means companies can innovate and create new applications, fostering creativity in product development and infrastructure projects.

Future Prospects

As industries continue to evolve, the demand for innovative materials like OEM mesh steel is likely to rise. The focus on sustainable manufacturing processes and recycling is expected to influence the production techniques for mesh steel, leading to more environmentally-friendly options. Moreover, advancements in technology may allow for even more intricate designs and higher-performance materials.

In conclusion, OEM mesh steel represents a blend of durability, versatility, and cost-effectiveness that meets the diverse needs of various sectors. As manufacturers continue to innovate and improve their offerings, the future of OEM mesh steel looks promising, promising to play a pivotal role in shaping modern infrastructure and industrial practices.

share

-

Safety Mesh for Windows – Durable Mosquito and Insect Protection Solutions

NewsJul.08,2025

-

12x24x1 Air Filter – High Efficiency Replacement for Improved Air Quality

NewsJul.08,2025

-

Premium Stainless Steel Mosquito Mesh - Durable, Rust-Resistant Protection for Windows & Doors

NewsJul.08,2025

-

Premium Stainless Steel Garden Mesh for Lasting Durability Best & High Quality Mesh Solutions

NewsJul.07,2025

-

Gold and White Blackout Curtains – Elegant Light Blocking & Insulation for Home

NewsJul.07,2025

-

Premium Spa Filter Cartridge for Clean Water Spa Pool Filters Cartridges for Jacuzzi Durable, high-efficiency spa filter cartridge for spas and jacuzzis. Improve water quality—order your pool filter cartridge now!

NewsJul.07,2025