okt . 19, 2024 09:10 Back to list

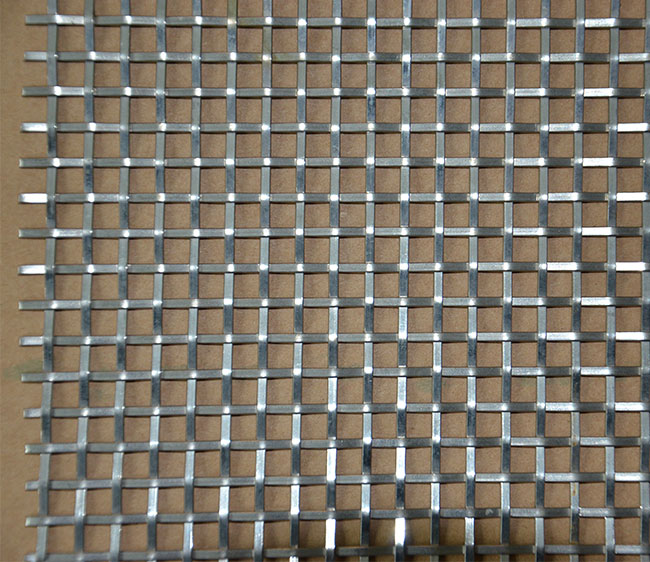

oem stainless steel wire filter

The Essential Role of OEM Stainless Steel Wire Filters in Modern Industries

In today’s fast-paced industrial landscape, precision and reliability are paramount. One critical component that contributes to these objectives is the OEM (Original Equipment Manufacturer) stainless steel wire filter. These filters are indispensable in various applications across multiple sectors due to their durability, resistance to corrosion, and ability to maintain high performance under pressure.

What Are OEM Stainless Steel Wire Filters?

OEM stainless steel wire filters are custom-manufactured filtration devices designed to meet specific requirements set by the original equipment manufacturers. Unlike standard filters, OEM filters are tailored to fit existing machinery or systems, ensuring optimal performance and compatibility. Typically made from high-quality stainless steel, these filters possess excellent mechanical properties, making them suitable for demanding environments.

Advantages of Stainless Steel Wire Filters

1. Corrosion Resistance Stainless steel is well-known for its resistance to rust and corrosion, which is crucial for filters exposed to harsh chemicals or outdoor environments. This resistance extends the lifespan of the filter and reduces maintenance costs.

2. Strength and Durability The structural integrity of stainless steel wire filters is another significant advantage. They can withstand high pressure and temperature variations, making them ideal for use in the oil and gas industry, food processing, pharmaceuticals, and other demanding applications.

3. Ease of Cleaning Unlike other materials, stainless steel can be easily cleaned and reused, making these filters more sustainable. This capability is particularly valuable in industries where hygiene is paramount, such as food and beverage production.

5. Customization Since these filters are OEM products, manufacturers have the flexibility to create designs tailored to unique specifications, including size, shape, and filtration capacity. This customization enhances efficiency and ensures that systems operate at their peak performance.

oem stainless steel wire filter

Applications Across Industries

The versatility of OEM stainless steel wire filters allows them to be employed in a myriad of industries.

- Oil and Gas In this sector, the filters are used to separate debris and contaminants from crude oil and natural gas, ensuring that the extraction and refinement processes are efficient and free from blockage.

- Food and Beverage In food processing, these filters play a crucial role in improving product quality by removing unwanted particulates while maintaining the integrity of the food.

- Pharmaceuticals Stainless steel filters are vital in pharmaceutical production to ensure that the final products are free from contaminants, which is essential for safety and compliance with regulatory standards.

- Water Treatment OEM stainless steel wire filters are integral to water purification systems, helping to ensure clean drinking water by filtering out impurities.

- Automotive and Aerospace These filters are used in fuel and lubricant systems to prevent engine wear and improve performance, contributing to the longevity and reliability of vehicles and aircraft.

Conclusion

In conclusion, OEM stainless steel wire filters offer a compelling solution to the filtration needs of various industries. Their unique combination of durability, corrosion resistance, ease of maintenance, and customization capabilities make them a preferred choice for manufacturers looking to enhance the productivity and safety of their operations. As industries continue to evolve and embrace new technologies, the demand for high-quality filtration solutions will only grow, solidifying the role of OEM stainless steel wire filters in the future of manufacturing and processing. Investing in these filters not only ensures compliance with industry standards but also promotes efficiency, sustainability, and long-term success.

share

-

Best & High-Quality Decorative Metal Wire Mesh OEM Services

NewsMay.20,2025

-

36 Chain Link Fence Durable 8ft,12ft,60ft Security Fencing Solutions

NewsMay.20,2025

-

Stainless Steel Weld Mesh Suppliers High-Strength & Corrosion-Resistant

NewsMay.20,2025

-

5mm Stainless Steel Mesh Best Quality & Custom OEM Solutions

NewsMay.19,2025

-

20x25x4 Furnace Filter MERV 11 Dust & Allergen Defense, 60+ Day Protection

NewsMay.19,2025

-

Ornamental Expanded Metal Sheets Durable & Custom Garden Designs

NewsMay.19,2025