nov . 25, 2024 01:08 Back to list

Wholesale Stainless Steel Wire Mesh Production Equipment for Various Industries

Wholesale Stainless Steel Wire Mesh Machine An Industry Overview

Stainless steel wire mesh has become an indispensable material in various industries due to its durability, corrosion resistance, and versatility. The demand for high-quality wire mesh has led to the development of sophisticated manufacturing machines, which are essential for producing different types of wire mesh efficiently. This article will explore the wholesale market for stainless steel wire mesh machines, their applications, and key considerations for buyers.

Understanding Stainless Steel Wire Mesh Production

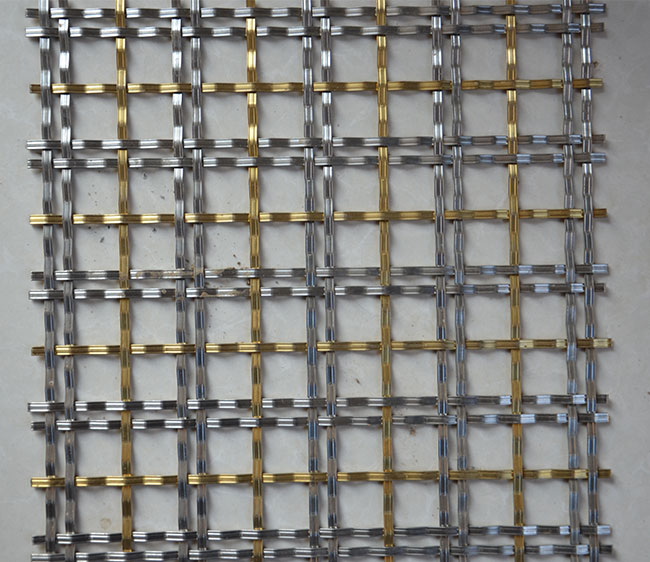

Stainless steel wire mesh is manufactured by weaving together fine strands of stainless steel wire. The weaving process can vary—for instance, it may include plain weave, twill weave, or Dutch weave. The choice of weaving technique affects the mesh's characteristics, such as its strength, permeability, and appearance. This material is widely used in construction, filtration, automotive, and food processing industries, among others.

The production of stainless steel wire mesh machines involves advanced technology, which allows for high-speed operation, precision, and efficiency. Manufacturers can produce various mesh sizes and styles, accommodating diverse customer needs. As the industry evolves, there is an increasing emphasis on automation, reducing manual labor costs and enhancing production rates.

Types of Stainless Steel Wire Mesh Machines

1. Wire Drawing Machines These machines reduce the diameter of stainless steel wire through a series of dies, preparing it for further processing. The precision of wire drawing affects the quality of the final mesh product.

2. Weaving Machines The heart of the production process, weaving machines interlace the drawn wire into mesh. Different types of weaving machines produce different mesh patterns, with some allowing for custom configurations based on client specifications.

3. Mesh Cutting Machines After weaving, the mesh must be cut to specific dimensions. Cutting machines can be programmed for precise measurements, ensuring minimal waste and optimal use of materials.

4. Finishing Machines These machines treat the woven mesh to enhance its properties, such as applying anti-rust coatings or polishing the surface. This step is crucial for applications that require aesthetic appeal or additional durability.

Advantages of Wholesale Purchase

Opting for wholesale stainless steel wire mesh machines offers several advantages for businesses

wholesale stainless steel wire mesh machine

- Cost Savings Buying in bulk often leads to significant discounts. Wholesale suppliers can provide competitive pricing that reduces the overall investment.

- Variety Wholesale distributors usually offer a range of machines, allowing businesses to select models that best suit their production needs.

- Improved Relationships Establishing a relationship with a reliable wholesale supplier can lead to long-term benefits, such as consistent supply, better customer service, and possible financing options.

Key Considerations for Buyers

When considering the purchase of stainless steel wire mesh machines, buyers should take several factors into account

1. Quality and Reliability Evaluate the quality of the machines offered by suppliers. Look for reviews and testimonials to ensure that the machines are reliable and built to last.

2. Technical Support Ensure that suppliers offer robust technical support and training services. This is crucial for minimizing downtime and maintaining productivity.

3. Customization Options If your business has specific requirements, seek out suppliers who can provide customization options for their machines.

4. After-sales Service Good after-sales service is essential for troubleshooting and maintenance, ensuring that the machines operate smoothly over their lifespan.

5. Compliance and Standards Check that the machines comply with industry standards and regulations. Compliance can affect operational efficiency and safety.

Conclusion

Wholesale stainless steel wire mesh machines play a critical role in the production of high-quality mesh for various applications. By understanding the different types of machines available, the advantages of wholesale purchasing, and the key considerations when buying, businesses can enhance their manufacturing operations and meet the growing demands of their respective industries. Investing in reliable machinery not only boosts production efficiency but also ensures the delivery of superior products to the market, ultimately contributing to business success.

share

-

Metal Fly Curtains Durable Insect Barrier & Ventilation Solution

NewsMay.15,2025

-

ODM Steel Crimped Mesh High-Strength & Customizable Solutions

NewsMay.15,2025

-

Wire Mesh Filter Elements Durable & Affordable Filtration Solutions

NewsMay.14,2025

-

Professional Chain Link Fence Installation Services Fast & Affordable

NewsMay.14,2025

-

Premium Dutch Woven Wire Cloth Exporter Durable & Versatile Solutions

NewsMay.13,2025

-

Best Galvanized Wire Mesh for Gabion Baskets OEM & Durable

NewsMay.13,2025