jan . 09, 2025 11:40 Back to list

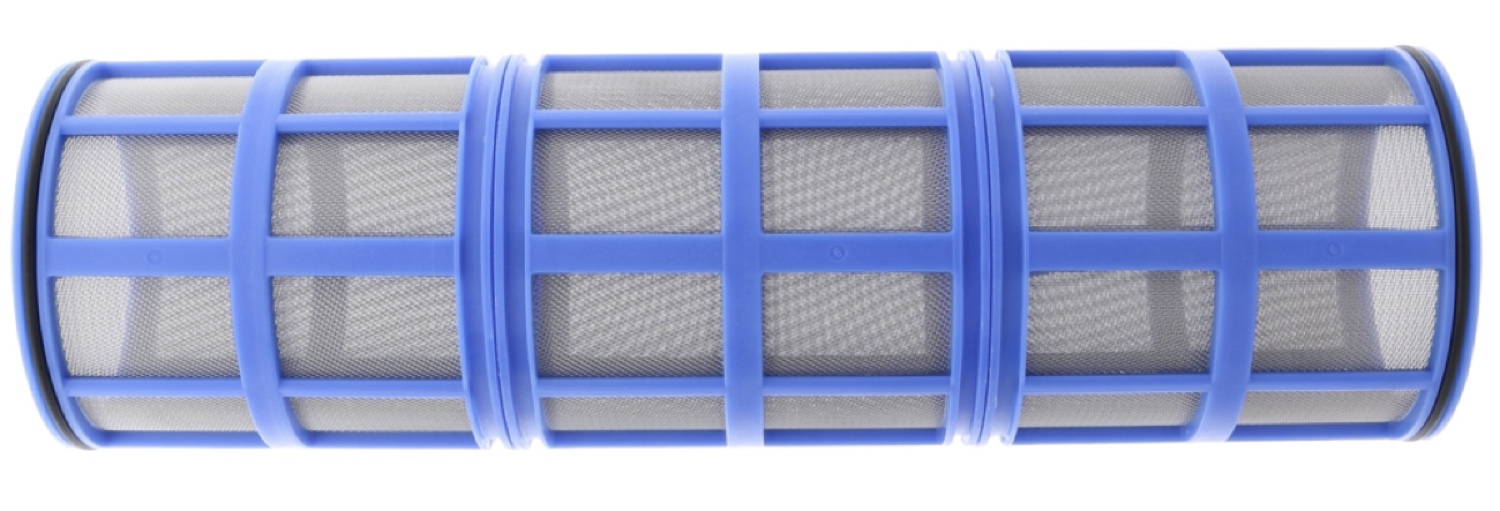

304 stainless steel wire cloth

Wire cloth, also known as woven wire mesh, is an integral component in numerous industrial applications. Understanding its functionality, manufacturing processes, and diverse applications can offer a competitive edge to businesses looking to optimize their operational efficiency.

Authoritativeness in wire cloth production and utilization is often established through extensive field testing and certification by recognized bodies. Products that meet rigorous standards, such as ISO and ASTM certifications, reassure consumers of their quality and reliability. These wire cloths undergo stringent testing protocols to verify their performance under simulated real-world conditions. Such certifications not only affirm their authoritativeness but also enhance trustworthiness among consumers and industry professionals. The trustworthiness of wire cloth extends to its ability to enhance safety, efficiency, and environmental sustainability in industrial operations. Industries such as aerospace and pharmaceuticals, which demand high precision, rely immensely on the trust engendered by certified and thoroughly tested wire cloth materials. This trust is built over years of proven performance and the consistent delivery of specifications promised by manufacturers. Businesses harnessing the potential of wire cloth stand to benefit significantly in enhancing their productivity. The authentic knowledge from industry practitioners, combined with cutting-edge technological advancements in manufacturing, offers a robust framework for selecting the right type of wire cloth for specific applications. In conclusion, wire cloth is more than just a mesh. It is a critical industrial material that underscores the importance of experience, expertise, authoritativeness, and trustworthiness in its production and application. By leveraging industry-leading techniques and maintaining stringent quality standards, manufacturers and users of wire cloth can ensure that they achieve operational excellence, reinforcing their position in a competitive market landscape.

Authoritativeness in wire cloth production and utilization is often established through extensive field testing and certification by recognized bodies. Products that meet rigorous standards, such as ISO and ASTM certifications, reassure consumers of their quality and reliability. These wire cloths undergo stringent testing protocols to verify their performance under simulated real-world conditions. Such certifications not only affirm their authoritativeness but also enhance trustworthiness among consumers and industry professionals. The trustworthiness of wire cloth extends to its ability to enhance safety, efficiency, and environmental sustainability in industrial operations. Industries such as aerospace and pharmaceuticals, which demand high precision, rely immensely on the trust engendered by certified and thoroughly tested wire cloth materials. This trust is built over years of proven performance and the consistent delivery of specifications promised by manufacturers. Businesses harnessing the potential of wire cloth stand to benefit significantly in enhancing their productivity. The authentic knowledge from industry practitioners, combined with cutting-edge technological advancements in manufacturing, offers a robust framework for selecting the right type of wire cloth for specific applications. In conclusion, wire cloth is more than just a mesh. It is a critical industrial material that underscores the importance of experience, expertise, authoritativeness, and trustworthiness in its production and application. By leveraging industry-leading techniques and maintaining stringent quality standards, manufacturers and users of wire cloth can ensure that they achieve operational excellence, reinforcing their position in a competitive market landscape.

share

Latest news

-

CE Certified 250 Micron Stainless Steel Mesh for Precision Filtration

NewsAug.22,2025

-

CE Certified 250 Micron SS Mesh - Precision Filtration & Strength

NewsAug.21,2025

-

CE Certified Woven Wire Mesh Filters | Premium Filtration Solutions

NewsAug.19,2025

-

High-Performance Particle Filters: Optimal Mediums & Applications

NewsAug.18,2025

-

Competitive Screen Mesh Price | 1/4", 1/8", 1/2" Wire Mesh Screens

NewsAug.17,2025

-

CE Certified 250 Micron SS Mesh: Precision & Durability

NewsAug.15,2025